Solar thermal collector integrated with insulation decorative board and processing method

A technology for solar heat collectors and thermal insulation decorative panels, which is applied to solar heat collectors using working fluids, solar heat collectors, and solar thermal energy, and can solve high processing costs, high raw material prices, and difficulties in welding copper pipes and aluminum plates and other issues to achieve the effect of cost reduction and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

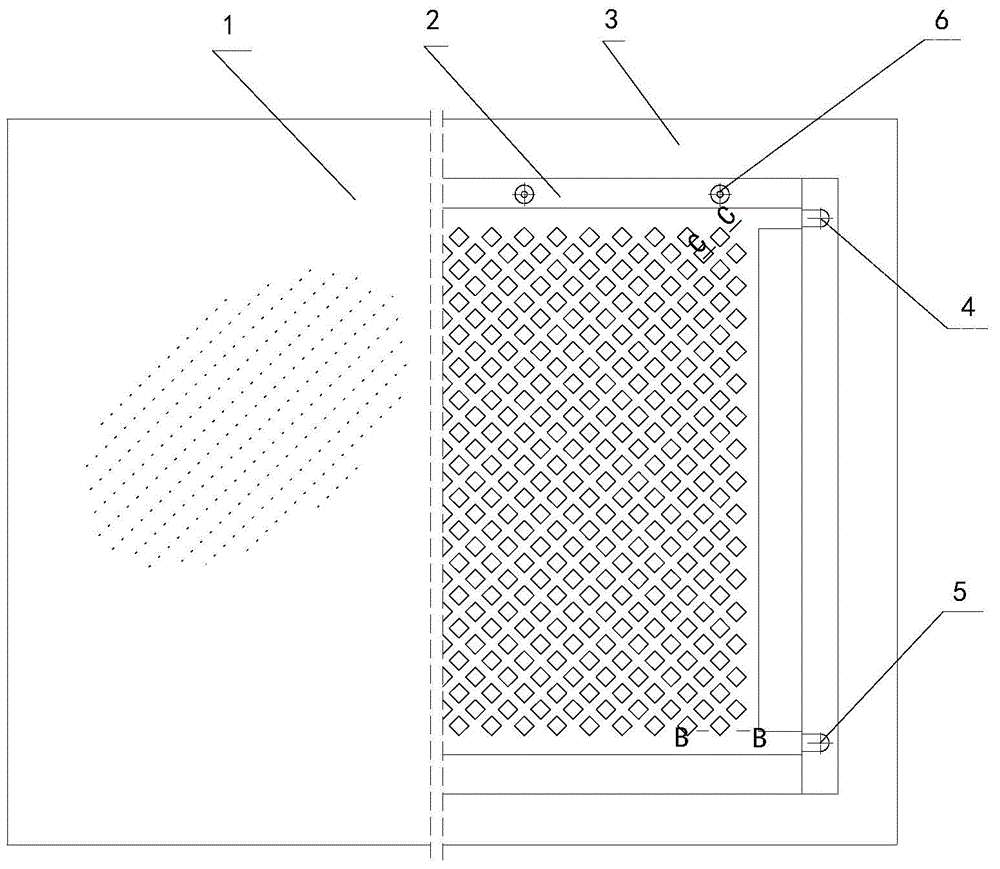

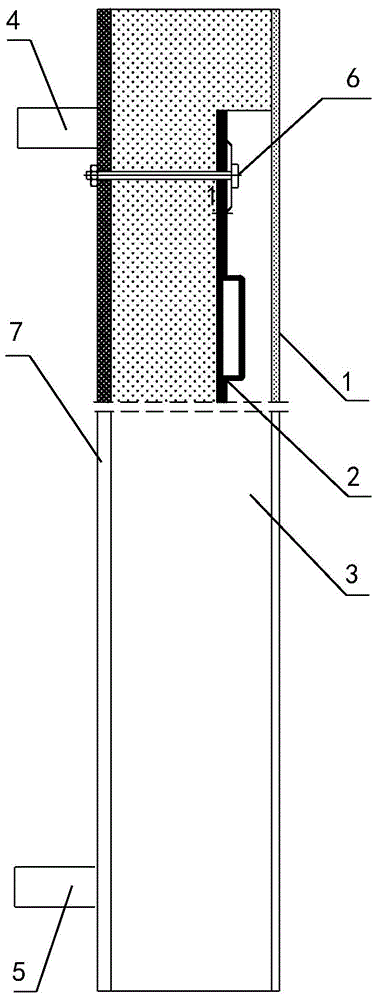

[0031] figure 1 , 2 The main structure of the heat collector of the present invention as shown includes a thermal insulation decorative panel and a grid-shaped plastic heat collector plate core 3 embedded in the thermal insulation decorative panel; the thermal insulation decorative panel consists of a back plate 7, an insulating layer 3 and a glass cover The plate 1 is composed of grid-shaped plastic heat-collecting plate core 2 connected with the back plate 7 of the thermal insulation decorative panel through anchoring assembly 6, and the grid-shaped plastic heat-collecting plate core is provided with water inlet and outlet joints 4,5.

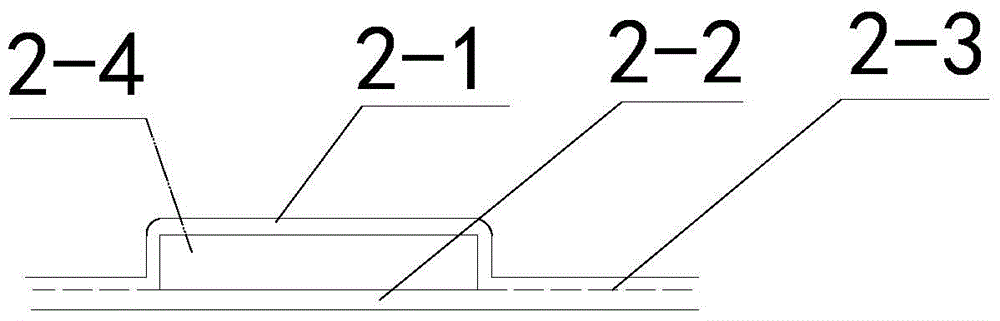

[0032] The grid-shaped plastic heat-collecting plate core is bonded by two plastic sheets or plastic films at multiple points, the bonded part 2-3 of the plate core is a plane, and the protruding part of the thick plastic sheet B 2-1 forms a grid, and the grid Inside is the connected water channel 2-4, such as image 3 , Figure 4 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com