Automatic continuous sampling device

A sampling device and automatic technology, applied to the sampling device and other directions, can solve the problems of high manufacturing cost, complex structure and complexity, and achieve the effects of low manufacturing cost, simple device structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

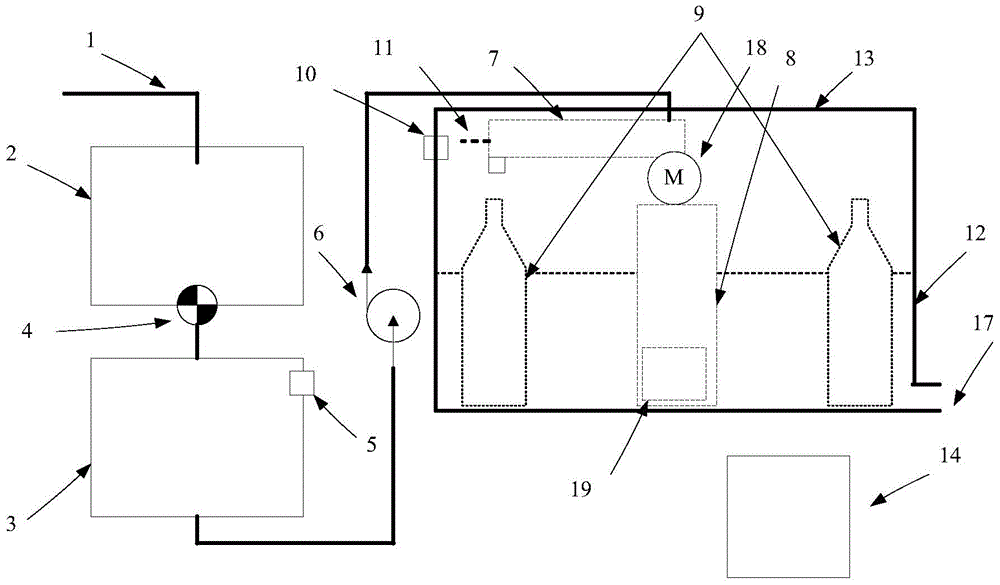

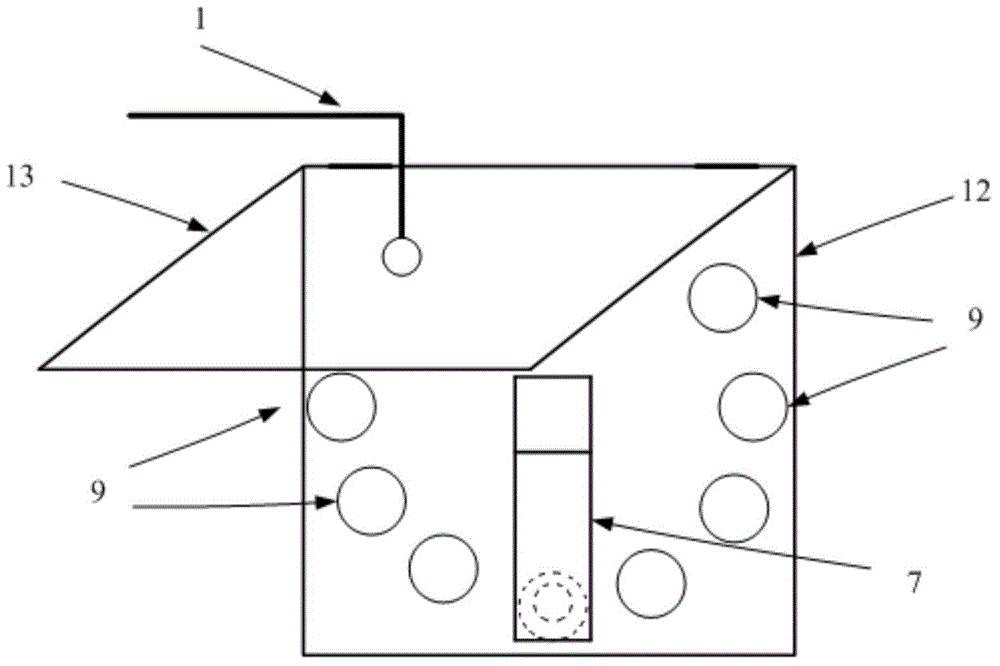

[0022] The structure of the automatic continuous sampling device provided by the invention is as figure 1 and figure 2 As shown, the device includes a buffer container A2, a buffer container B3, a buffer container C7, a sampling tank 12, a rotating platform 8 and a CPU controller 14. The buffer container A2, the buffer container B3 and the buffer container C7 can all be cuboid containers formed by bonding acrylic plastic materials. The buffer container A and the buffer container B are fixed by the bracket, the buffer container A is located directly above the buffer container B, the top of the buffer container A is provided with a liquid inlet pipe 1, and the bottom is provided with a liquid outlet pipe, and the liquid outlet pipe is connected to the top of the buffer container B Connected, and a solenoid valve 4 (AB4104-8-W-DC12V, Ningbo Kailing Pneumatic Componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com