Drop height fitting method

A critical drop height and height technology, applied in strength characteristics, measuring devices, instruments, etc., can solve problems such as test result deviation, material denaturation, and increased workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

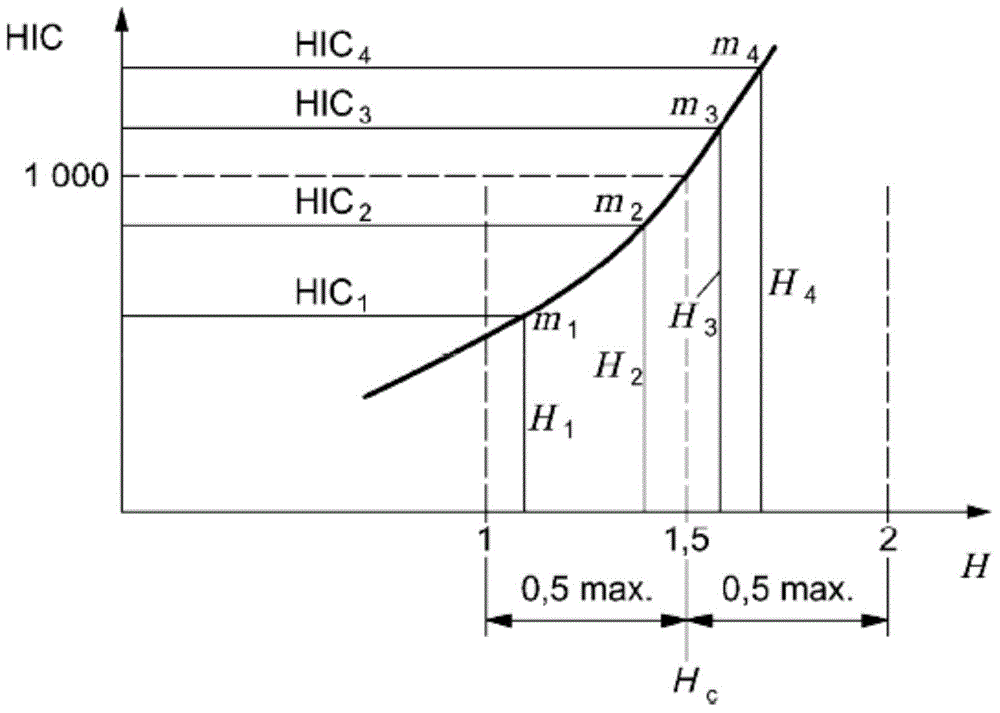

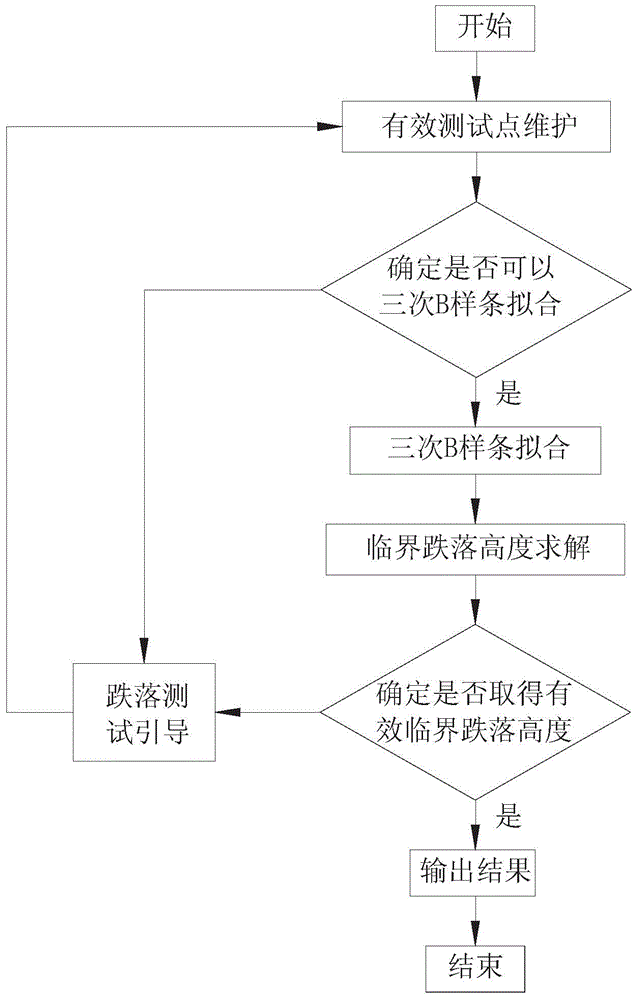

[0035] In order to achieve the purpose of the present invention, such as figure 2 As shown, in one of the embodiments of the present invention, a drop height fitting method is provided, comprising the following steps:

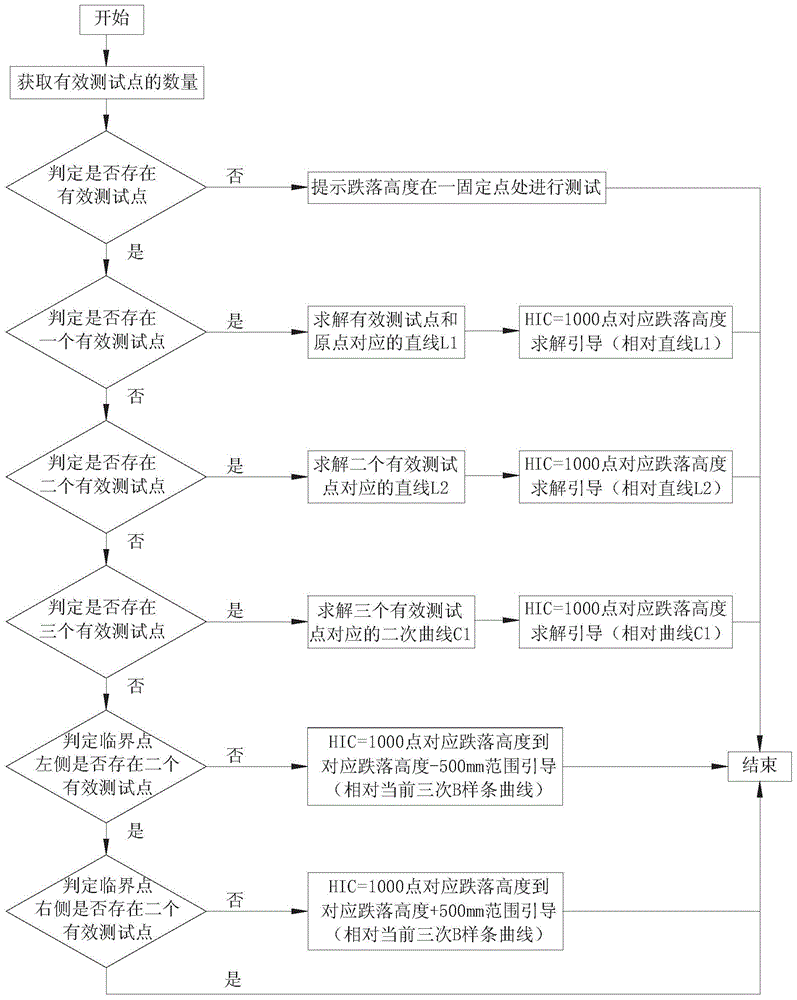

[0036] S1. Maintenance of effective test point list: The drop tester performs impact test, obtains the drop data of the impact test point and generates a test point list, and performs conflict analysis when adding the drop data of the new impact test point to the already generated test point list. If there is no conflict, enter step S2 after generating a new valid test point list; if there is a conflict, delete the conflict point according to the conflict determination rule, generate a new valid test point list and enter step S2;

[0037] S2, determine whether cubic B-spline fitting is possible: according to the new list o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com