High-temperature-resistant non-welded type radio-frequency coaxial cable connector

A technology of radio frequency coaxial cable and radio frequency cable, which is applied in the direction of connection, two-part connection device, and parts of the connection device, etc. It can solve the problems that cannot meet the requirements of high temperature environment, high operating process requirements, and low electrical performance indicators. , achieve the effects of simple structure, broad application prospects, and good electrical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

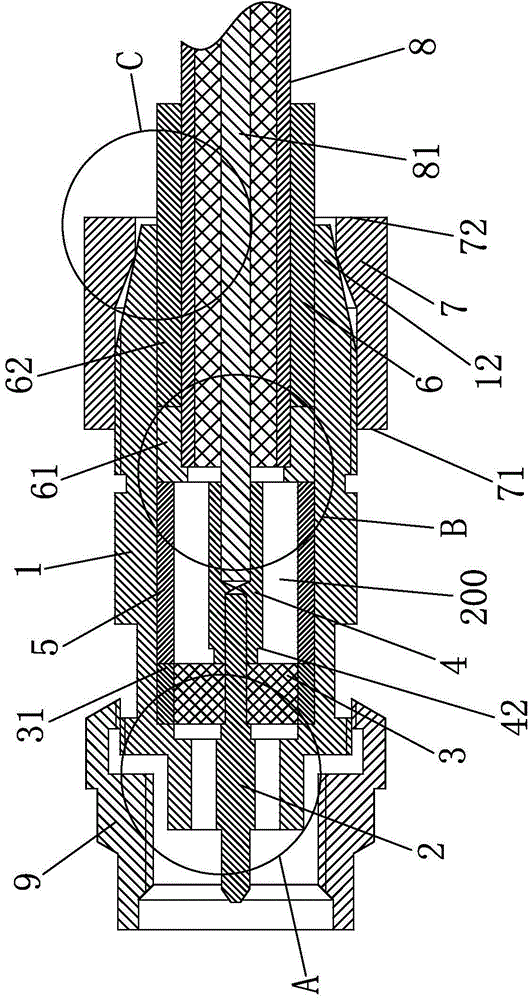

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

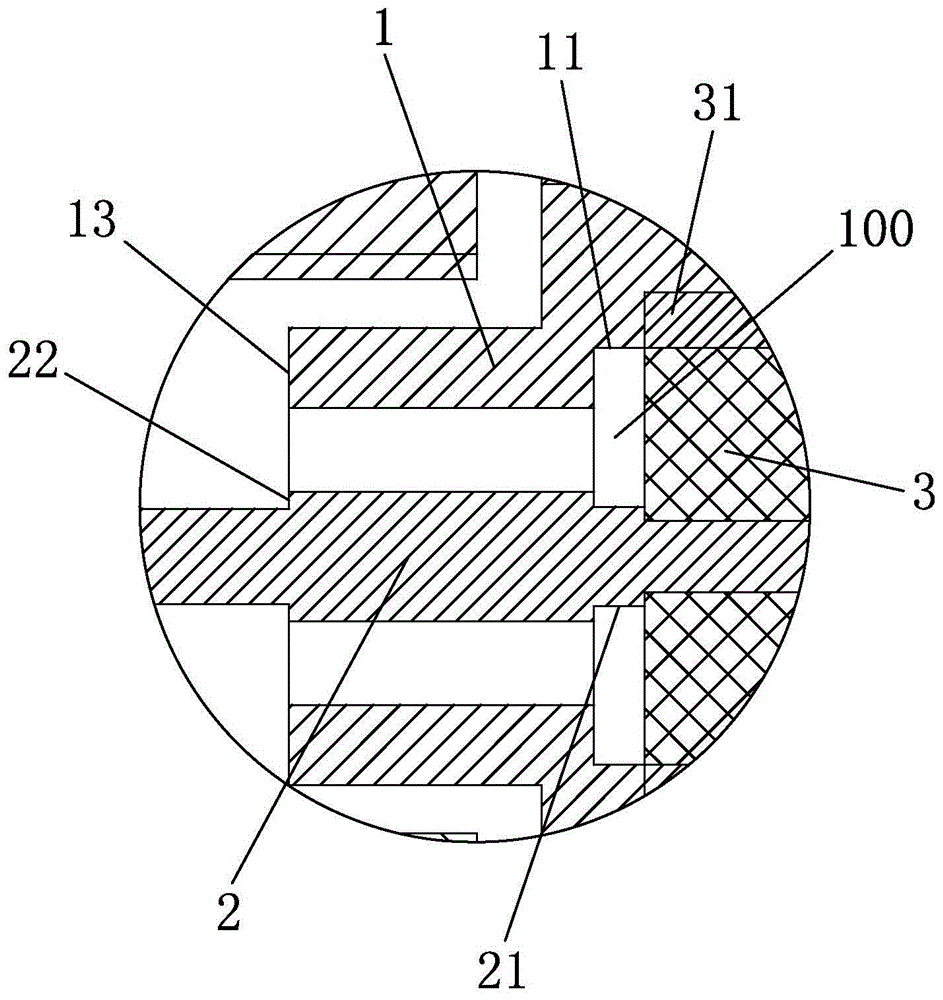

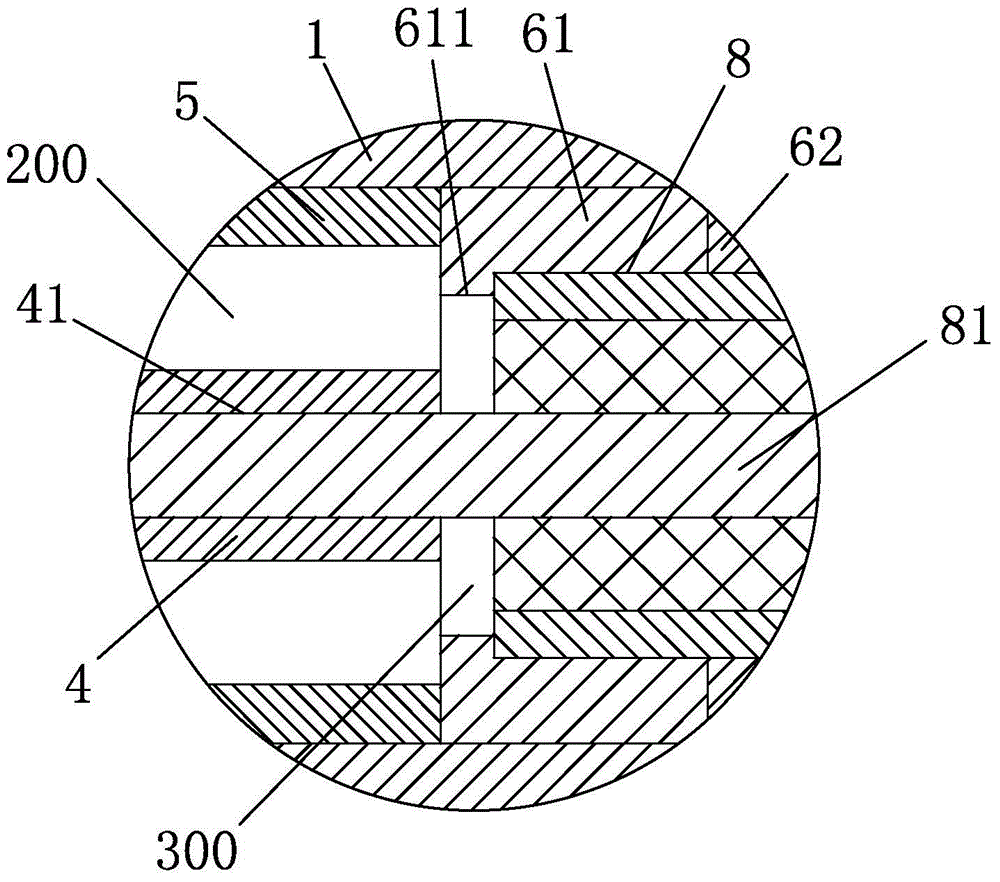

[0032] like Figures 1 to 5 As shown, a high temperature resistant non-welded radio frequency coaxial cable connector, the connector includes an outer conductor 1, a first inner conductor 2 arranged in the outer conductor 1, and a first inner conductor 2 arranged in the outer conductor 1 for preventing protection The retaining ring 5 that the ring 31 moves to the right, and a set of limit sleeves 6 arranged on the radio frequency cable 8 for fixing the relative position of the radio frequency cable 8 and the outer conductor 1 and preventing the retaining ring 5 from moving to the right.

[0033] The first inner conductor 2 is covered with a high temperature resistant insulating support 3. In this embodiment, the material of the high temperature resistant insulating support 3 is made of glass material; The first limit compensation step 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com