A dual-purpose machine for straightening and arc adjustment of multiple steel bars on site

A steel bar and direct adjustment technology, which is applied in the field of multi-steel bar back and straight arc adjustment dual-purpose machine, can solve the problems of increased production cost and maintenance cost, high price, large error, etc., and achieves easy control of the processing steel bar angle and high mechanical power. The effect of low and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is further described with reference to the accompanying drawings.

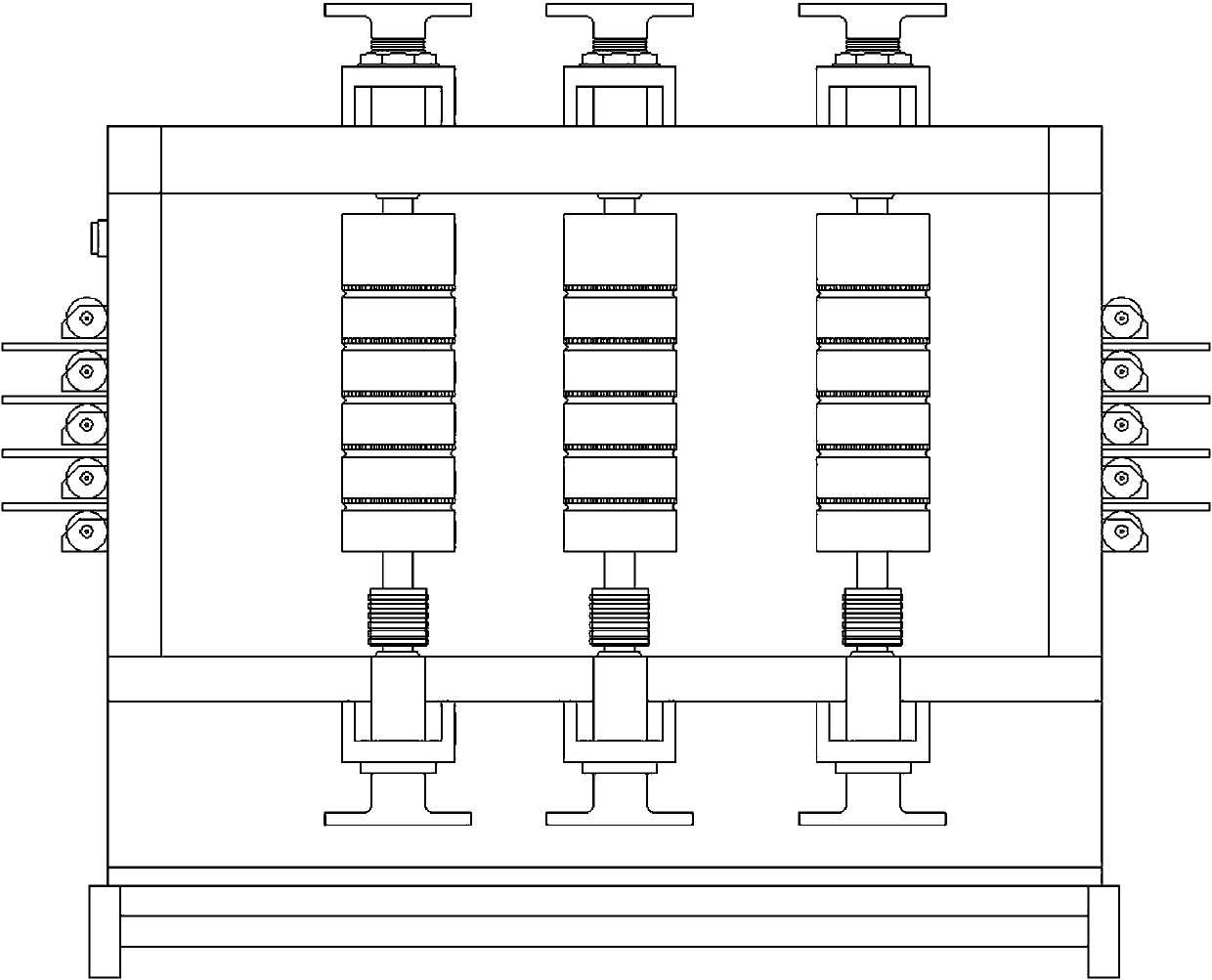

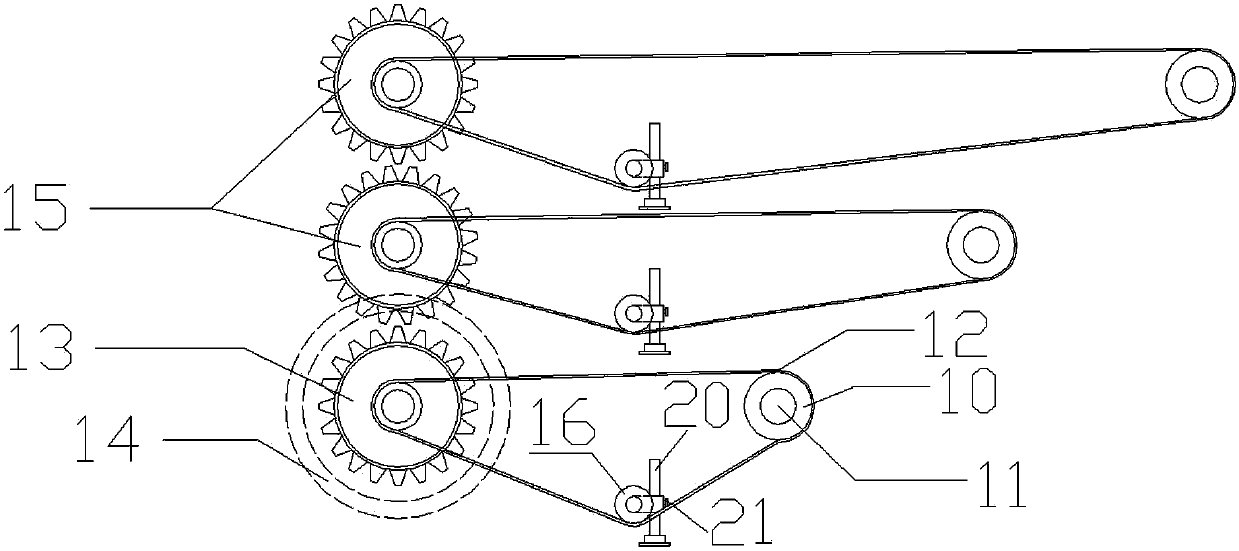

[0015] Such as figure 1 As shown, a dual-purpose machine for straightening and arc-adjusting multiple steel bars on site includes a frame 1, a power mechanism, and a mechanism for straightening and arc-adjusting steel bars. Some parallel conveying rollers 3 and several parallel multi-section grooved solid cylinders 8 installed in the vertical direction of the frame 1, the multi-section grooved solid cylinders 8 slide left and right relative to the frame 1 and can be fixed.

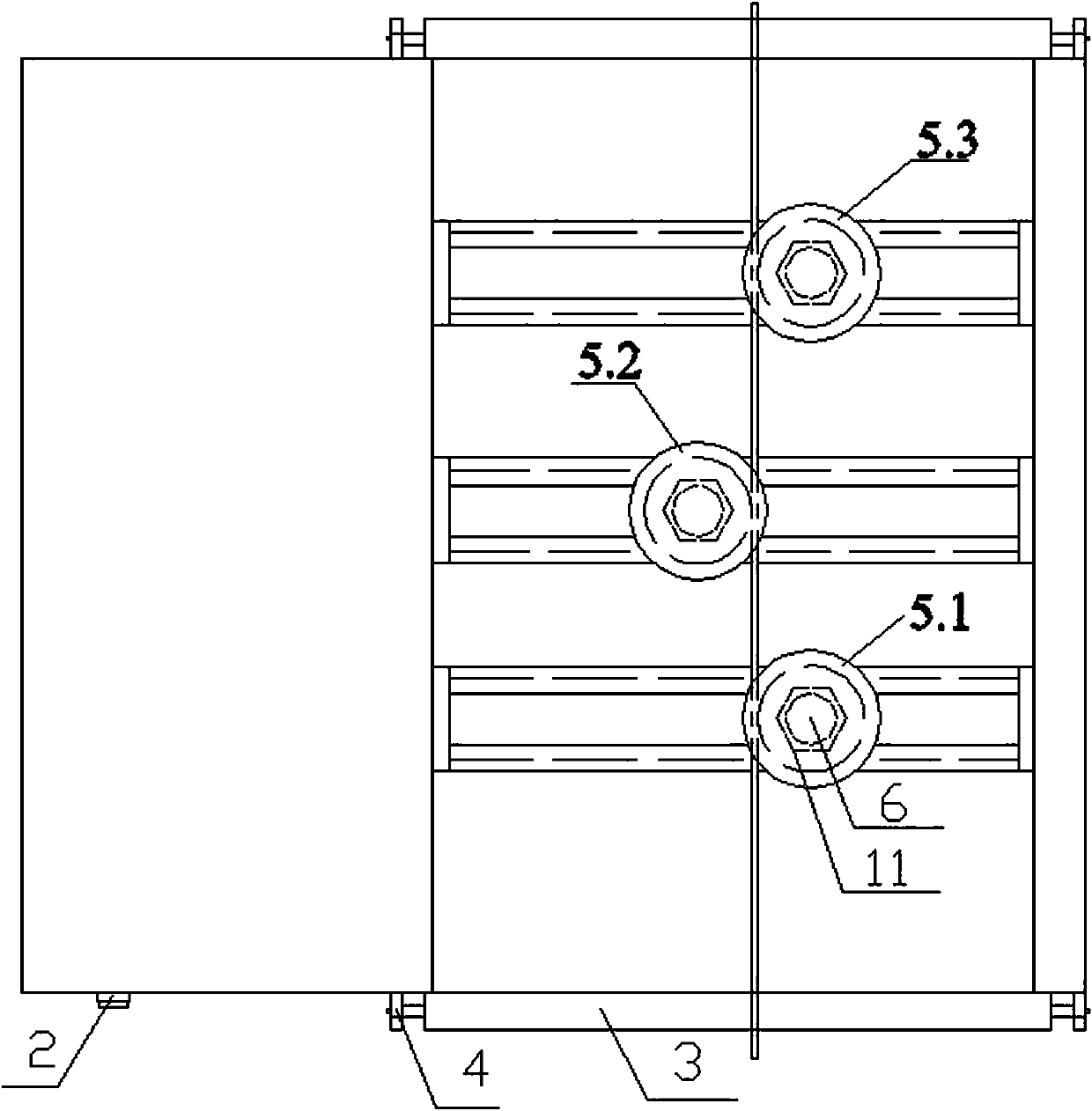

[0016] The frame 1 includes upper and lower beams and front and rear vertical beams. Several rows of guide chute 7 are symmetrically fixed on the upper and lower beams of the frame 1. The guide chute 7 is movably connected to the regulating valve 5, and the regulating valve 5 is internally inserted into the central axis screw rod 11. The multi-section grooved solid drum 8 is fixed on the central axis screw 11; the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com