Operation device and assembly line for automatically assembling upper and lower covers of shielding cases on line

An operating device and automatic assembly technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the number of pick-and-place actions, product surface pollution, and complicated actions, so as to simplify the design of manipulators and improve equipment efficiency. , the effect of simplifying the operation action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

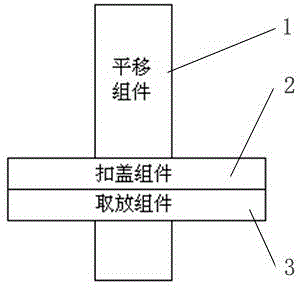

[0073] like figure 1 As shown, an operating device for automatically assembling the upper and lower covers of the shielding cover on-line includes a translation assembly 1, a button cover assembly 2 and a pick-and-place assembly 3, and the button cover assembly 2 and the pick-and-place assembly 3 are installed on the translation assembly 1 and Driven by the translation component 1, it moves back and forth horizontally.

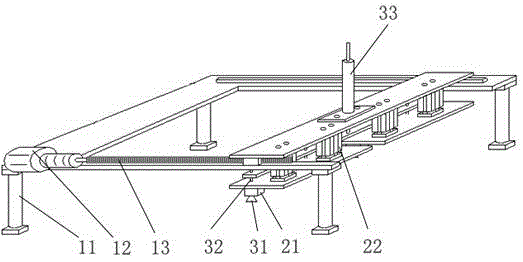

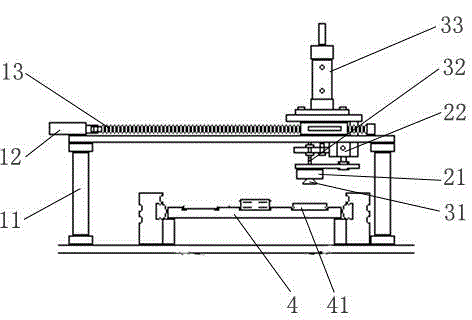

[0074] like figure 2 , 3 As shown, the translation assembly 1 includes a bracket 11 , a translation motor 12 and a screw 13 , the translation motor 12 is fixedly mounted on the bracket 11 , and the screw 13 is connected to the output end of the translation motor 12 .

[0075] like Figure 4 As shown, the pick-and-place assembly 3 includes a vacuum suction nozzle 31, an elastic floating air pipe 32, a pick-and-place air cylinder 33 and a vacuum generator 34. 34 connection, the output end of the pick-and-place cylinder 33 is fixedly connected to a connectin...

Embodiment 2

[0078] like Image 6 As shown, an assembly line for the online automatic assembly of the upper and lower covers of the shielding cover includes a number of carrying trolleys 4, and an operating device is installed on the side of the carrying trolley 4 that needs to operate the product. Each action of each operating device is controlled by the control system. The control system of each operating device is connected to a main controller through an external bus for unified control.

[0079] The operating device in this embodiment uses the operating device described in Embodiment 1.

[0080] Utilize the operating device of the present invention to complete the assembly process on the assembly line as follows:

[0081] 1. The carrying trolley 4 is conveyed on the assembly line. Before passing through the automatic cover-closing station, use manual or mechanical hands to place and position the metal upper cover, metal lower cover and metal enclosure to be assembled on the designat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com