Aluminum material cutting mechanism with low probability of vibration

A cutting mechanism and an uncompromising technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as large shaking force, offset of aluminum materials, and affecting the quality of cutting aluminum materials, so as to facilitate cutting operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

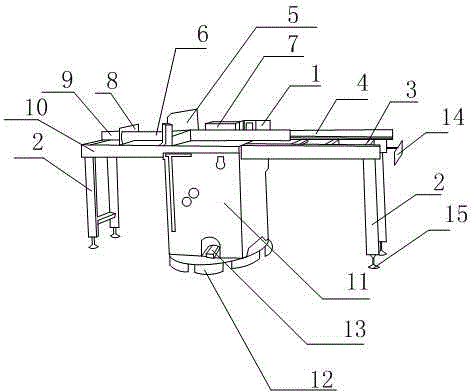

[0018] Such as figure 1 As shown, the present invention includes an aluminum cutting mechanism that is not prone to vibration, including a plurality of tripods 2, a feeding frame 3, a discharging frame 10, a support table 11 and a shock-proof block 12, the feeding frame 3 and the discharging frame One end of 10 is connected horizontally, and the supporting table 11 is vertically installed at the bottom of the horizontal plane formed by the feeding rack 3 and the discharging rack 10. A number of tripods 2 are vertically installed at the bottoms of both ends of the discharging rack 10 and the feeding rack 3. The top of the feeding rack 3 and the discharging rack 10 is also provided with a workpiece 6, and the workpiece 6 on the discharging rack 10 crosses the baffle 8. On the side of the workpiece 6 is also provided with a press rack 5, switch 1 and cutting oil tank 7 , A stopper 14 is also provided at the entrance of the feeding rack 3; a plurality of shock-proof blocks 12 are e...

Embodiment 2

[0020] This embodiment is preferably as follows on the basis of embodiment 1: a level adjustment screw 15 is provided at the bottom of each stand 2. It is used to adjust the angle of the plane formed by the feeding rack and the discharging rack to any situation to meet the needs of different aluminum cutting.

[0021] A stop plate 4 is also installed on the side of the feeding rack 3, and the stop plate 4 can slide back and forth.

[0022] The baffle 14 can slide back and forth.

[0023] A foot switch 13 is also arranged under the supporting platform 11.

[0024] A ruler 9 is also provided at one end of the workpiece 6. For some aluminum materials that are not cut in place, you can also use the foot switch to cut again separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com