A mold locking mechanism for blow molding equipment

A blow molding equipment and mold technology, applied in the field of mold locking mechanism, can solve the problems of reduced reliability of the mechanism, inability to eliminate, and inability to eliminate noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

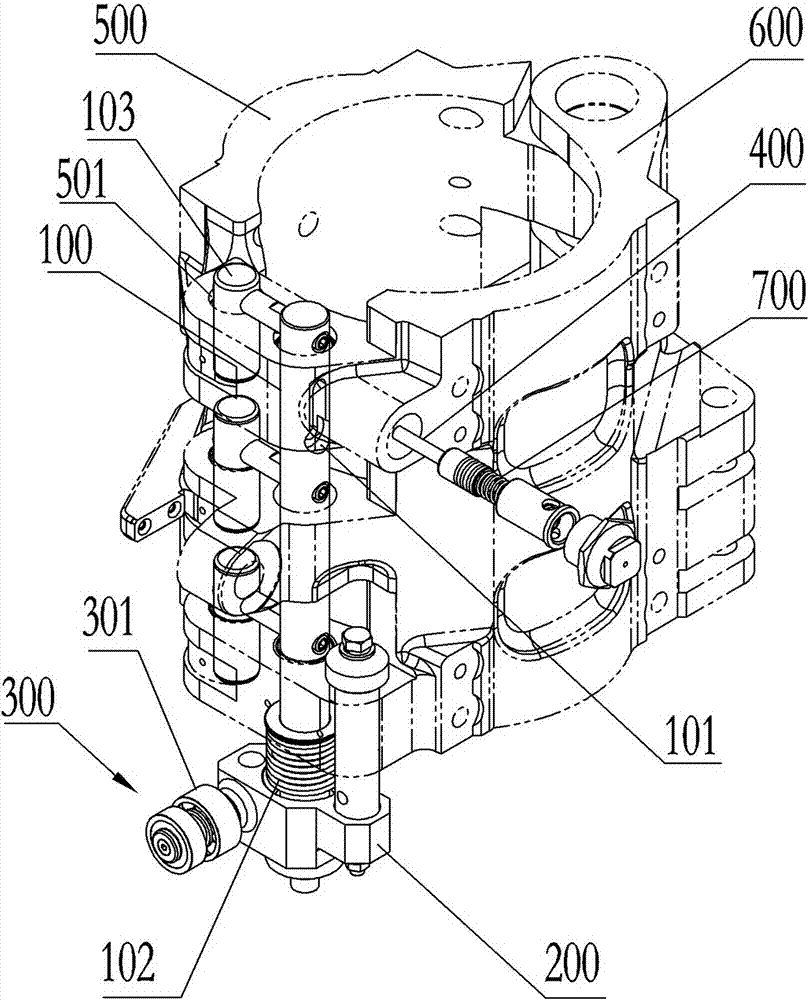

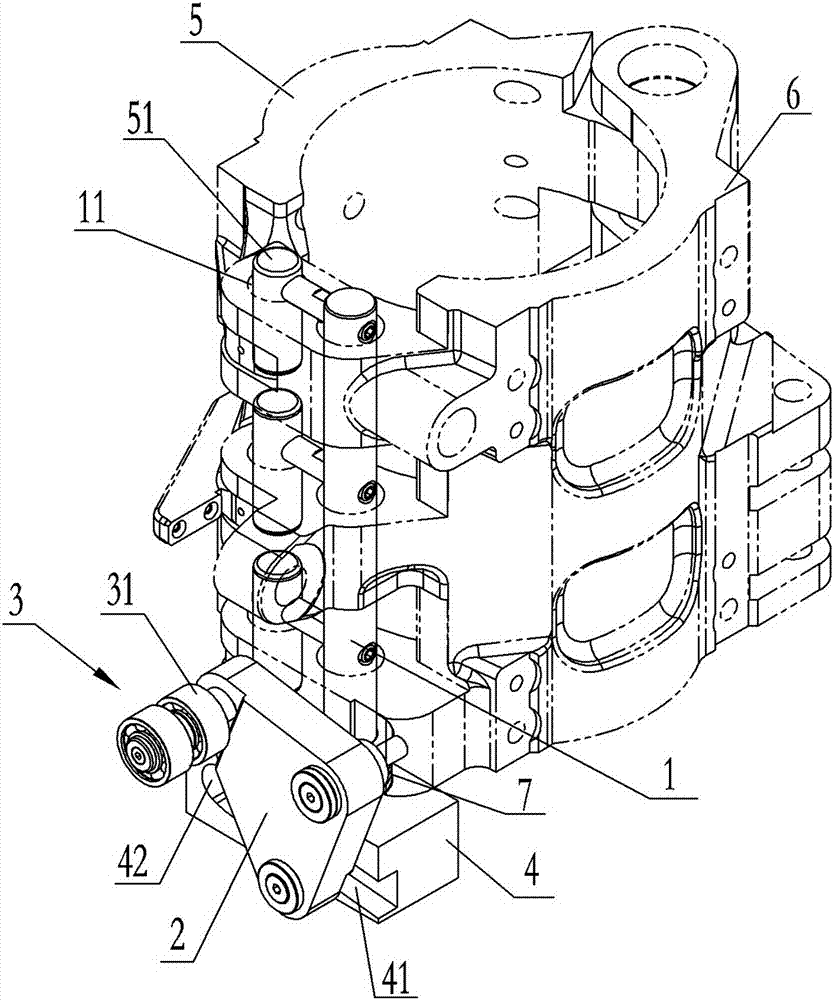

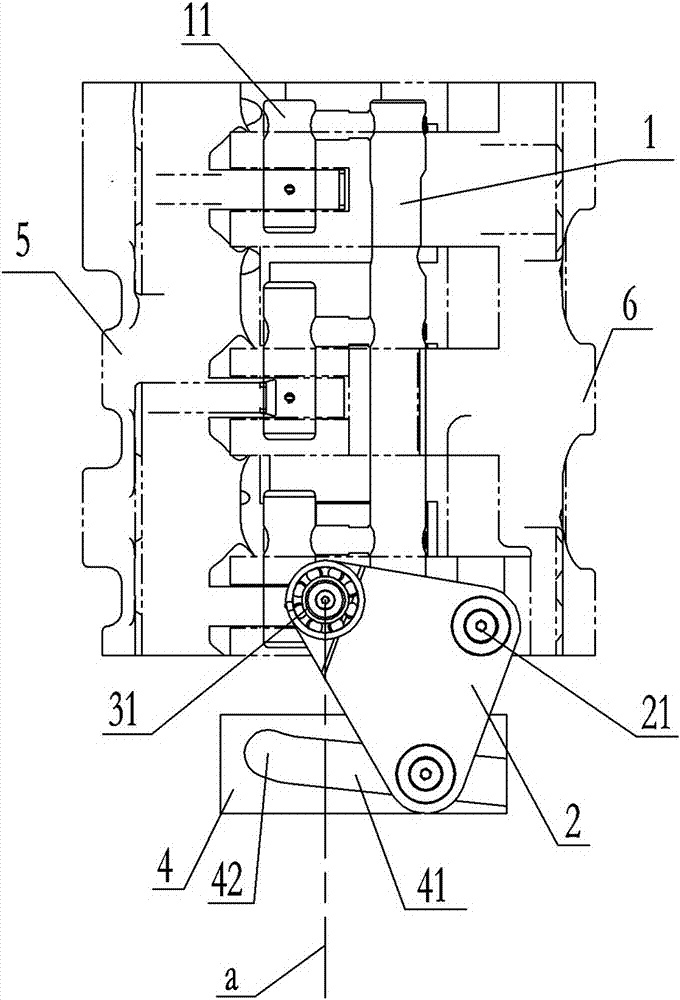

[0012] Such as Figures 2 to 4 As shown, a mold locking mechanism of blow molding equipment includes two mold frames 5, 6 installed on a rotating frame (not shown in the figure) and driven by a driving mechanism (not shown in the figure) to realize opening or closing , one of the mold frames 6 is equipped with a clamping shaft assembly 1 that can slide up and down and is hinged with a swing arm 2. The lower part of the locking shaft assembly 1 is fixed with a connecting block 4, and the lower part of the locking shaft assembly 1 is located at the bottom of the connecting block 4. The upper position is set with the booster top spring 7, the upper end of the booster top spring is against the mold frame 6, and the lower end is against the connecting block 4, exerting downward elastic force on the clamping shaft assembly 1, and the connecting block 4 and the swing arm 2 are opposite to each other. Sides are respectively provided with slideway 41 and toggle shaft 8 extending into s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com