Automatic liquid stopping type intravenous infusion unit

A technology for intravenous infusion and hemostasis, which is applied in the direction of instruments, drug devices, hypodermic injection devices, etc. It can solve problems such as difficulty in detection and understanding by patients, low reliability of sealing, deformation of floats, etc., to enhance trust and facilitate rapid transformation And upgrade, promote the effect of harmony

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

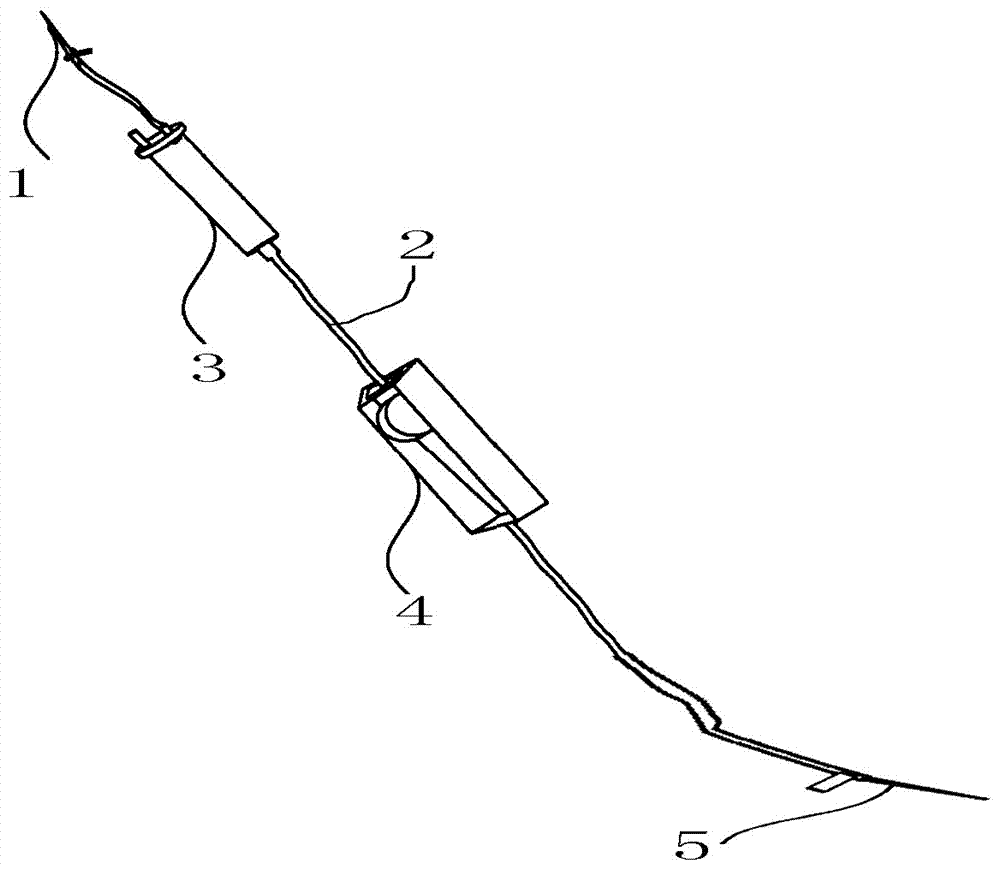

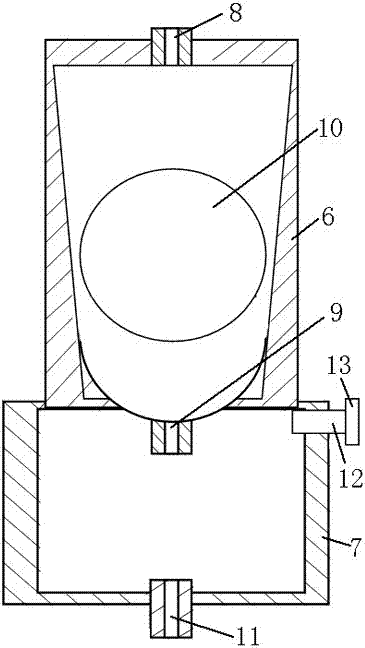

[0016] The infusion hose 2 connects the bottle stopper puncturer 1, the drip pot 3, the flow regulator 4, and the intravenous infusion needle 5 in sequence. The drip pot 3 is composed of the upper drip pot 6 and the lower drip pot 7, and the lower drip pot 7 is socketed on the The lower end of the upper drip pot 6; the cavity of the upper drip pot 6 is in the shape of an inverted cone; the upper end of the upper drip pot 6 is provided with a liquid inlet 8, and the cavity of the upper drip pot 6 is provided with a floating body 10, which is a spherical structure; A spherical structure with an upward opening is arranged between the upper drip pot 6 and the lower dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com