MDOF (multiple degree of freedom) coarse motion workpiece platform

A technology of degrees of freedom and workpiece table, which is applied in the field of lithography machines, can solve problems such as complex control, difficult design and processing of flexible blocks, and complex structure of coarse motion workpiece table, so as to reduce costs, facilitate installation, and reduce structural processing and assembly. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

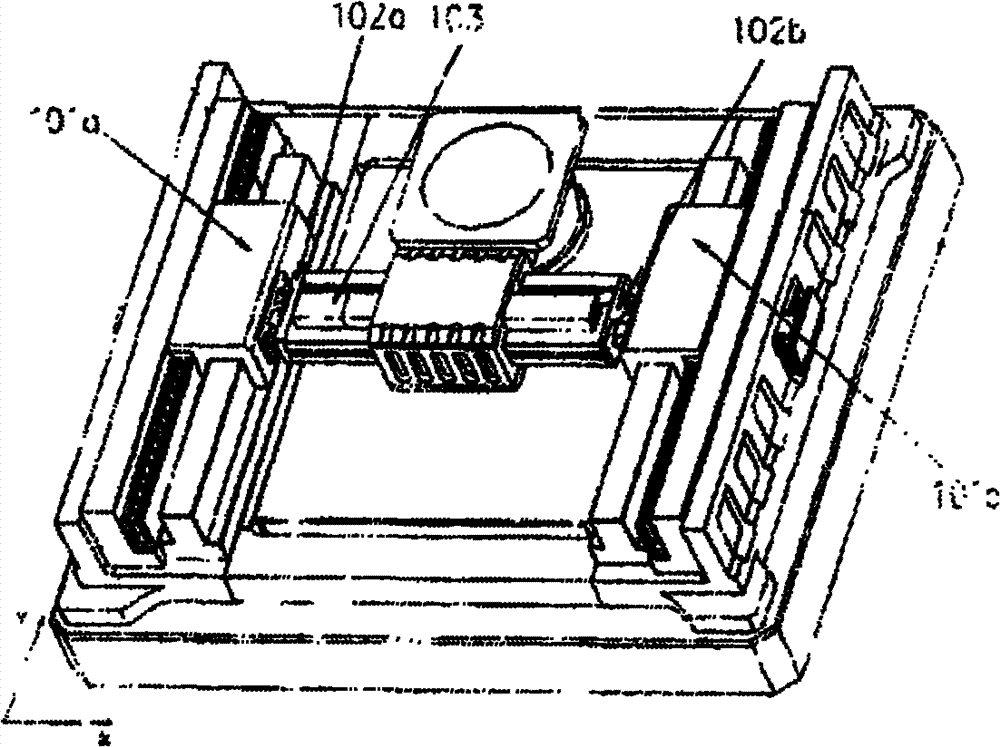

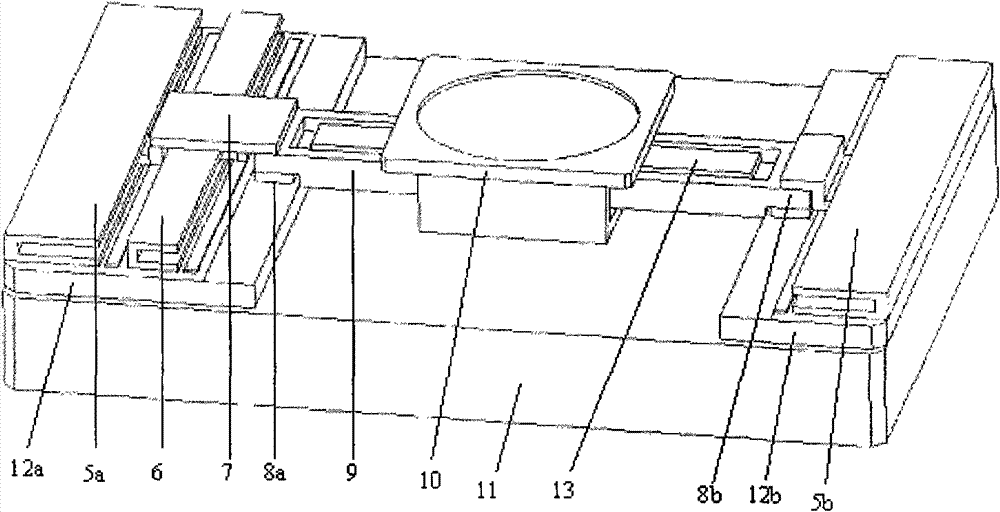

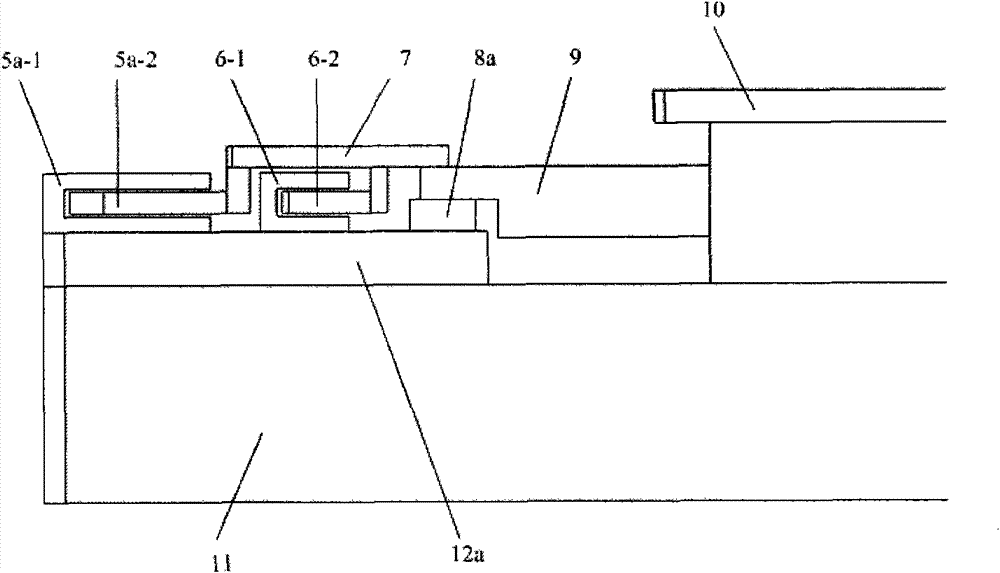

[0020] The following will combine Figure 2 ~ Figure 4 The multi-degree-of-freedom coarse motion workpiece table of the present invention is further described in detail.

[0021] see figure 2 , the marble plate 11 of the multi-degree-of-freedom rough motion workpiece table of the present invention, two motor supports 12a and 12b, two Y-direction long-stroke linear motors 5a and 5b, X-direction micromotor 6, connecting plate 7, two air floats Blocks 8a and 8b, crossbeam 9 workpiece table 10 and X-direction long-stroke linear motor 13;

[0022] The two motor supports 12a and 12b are respectively arranged on both sides of the marble slab 11;

[0023] The two Y-direction long-stroke linear motors 5a and 5b are separately arranged on the two motor supports 12a and 12b;

[0024] The X-direction micromotor 6 is arranged on the motor support 12a, and the X-direction micromotor 6 is parallel to the Y-direction long-stroke linear motor 5a;

[0025] The X-direction micromotor 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com