A Self-Balancing Storage Robot for Hazardous Locations

A dangerous place, self-balancing technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of glass bottle damage, failure to ensure material safety, failure to use, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

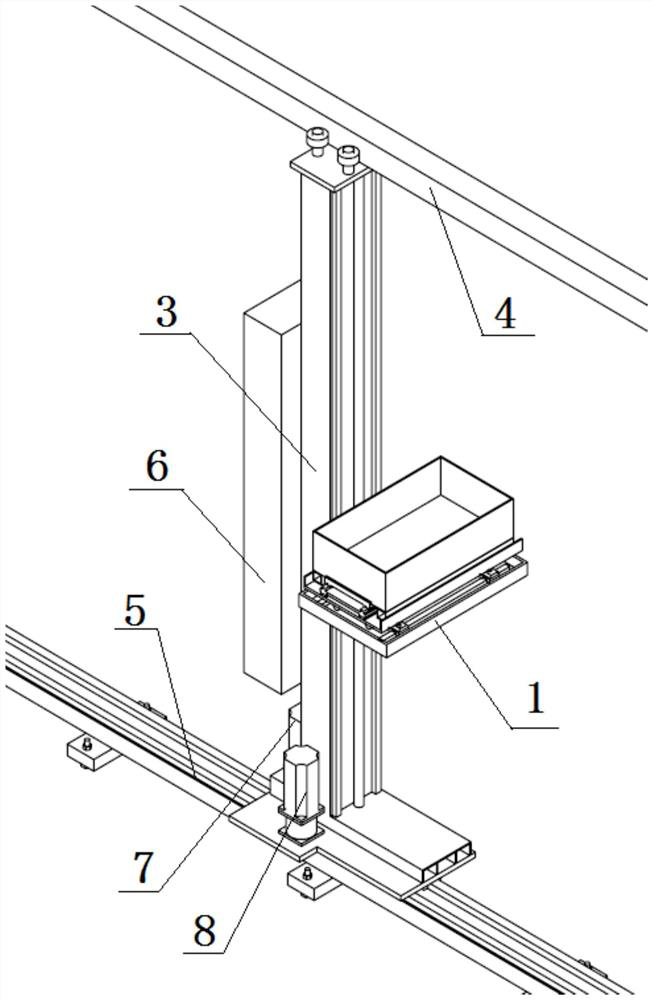

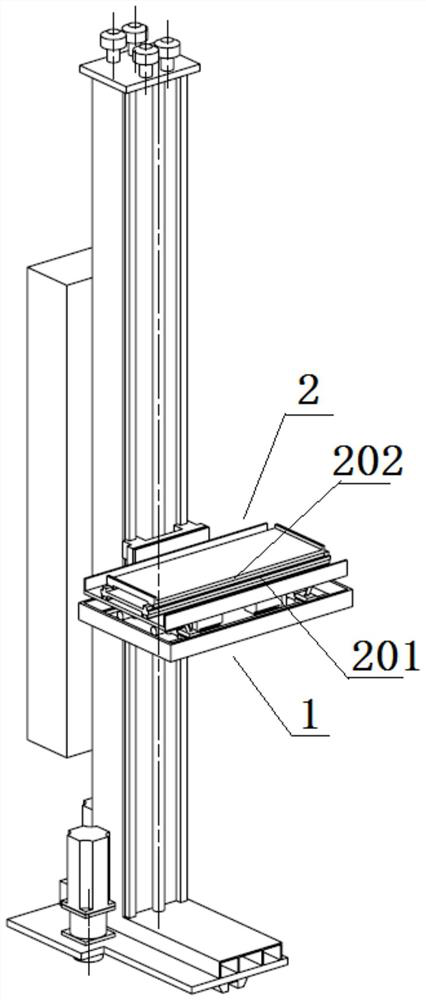

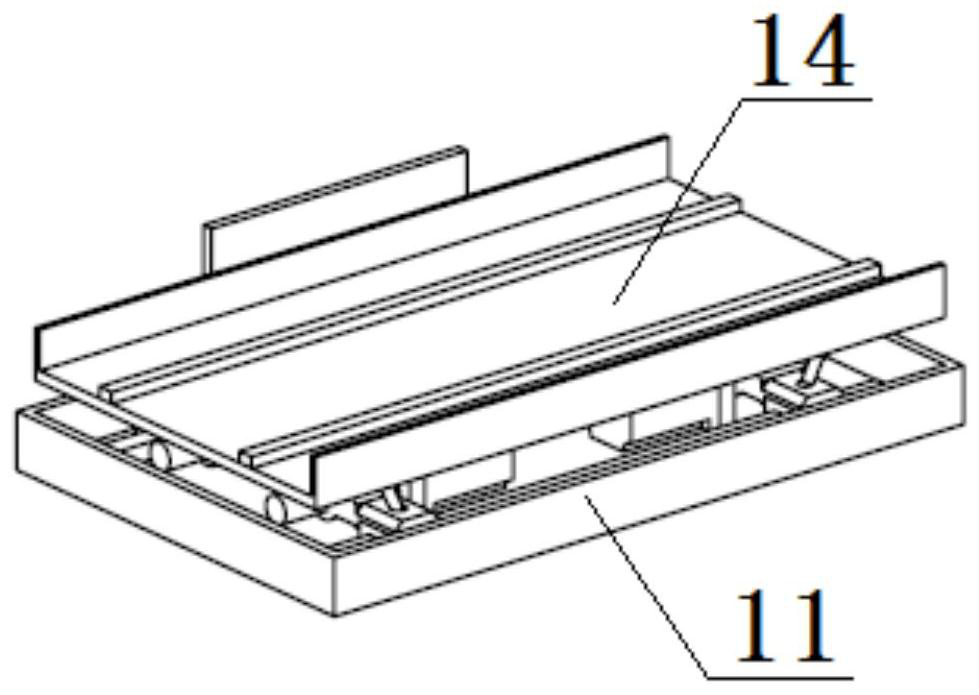

[0038] Example: as Figure 1 to Figure 6 As shown, a self-balancing storage robot for hazardous locations includes a self-balancing structure 1, the self-balancing structure 1 includes a bottom plate 11, a rotating central column 12, a balance adjustment group 13 and a balance plate 14;

[0039] The balance plate 14 is located above the bottom plate 11, and the middle part of the surface of the bottom plate 11 is connected to the middle part of the balance plate 14 through the rotating center column 12, and the top of the rotating center column 12 and the middle part of the balance plate 14 are hinged;

[0040] The surface of the bottom plate 11 is connected to the balance plate 14 through a plurality of balance adjustment groups 13 . The balance adjustment group 13 includes a motor seat 131 , a motor 132 , a ball screw pair 133 , a connection seat 134 and an adjustment column 135 . The motor 132 The motor seat 131 is arranged on the surface of the bottom plate 11, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com