A method for the preparation of rail rows in curved sections of urban rail construction

A technology for urban rails and curved sections, applied in the directions of rails, laying rails, rail maintenance, etc., can solve the problems of not taking into account the difference of the rail head phase offset and the distribution of sleepers, wasting rails, rail head damage, etc., to achieve neat arrangement. , Reduce the waste of raw materials, reduce the effect of impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Under the confidentiality agreement of the present invention, the method has been successfully tried out in track engineering in various places. Now take ZJD7 of Wuxi Metro Line 2 as an example:

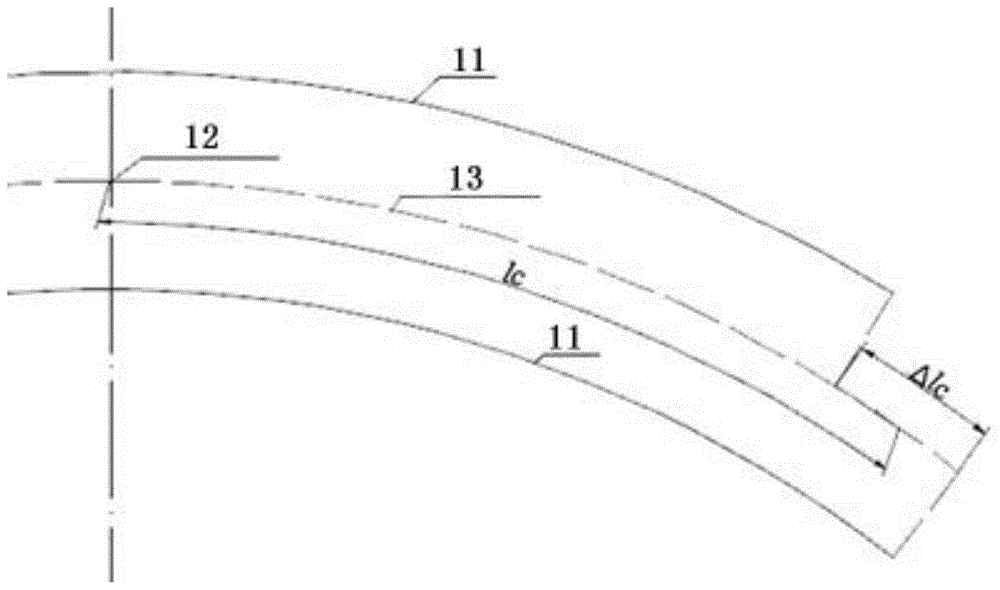

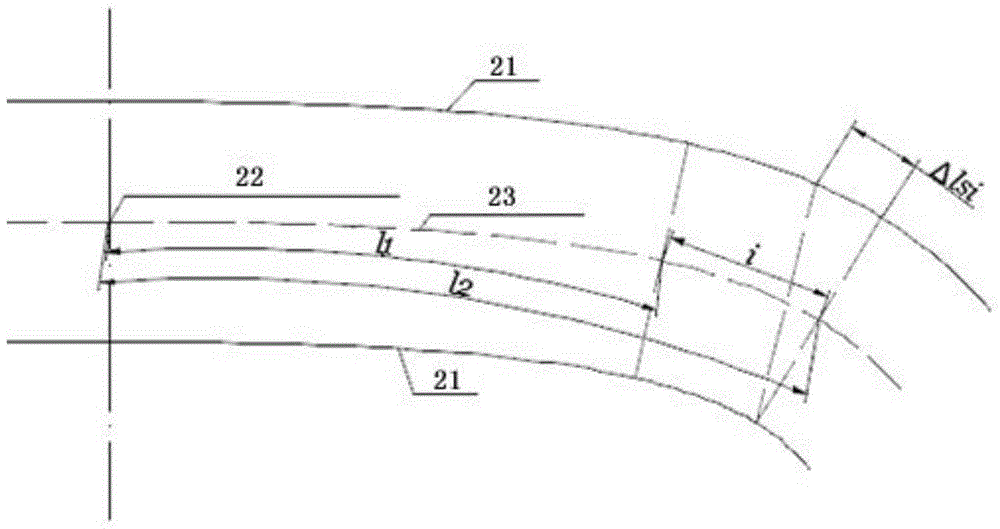

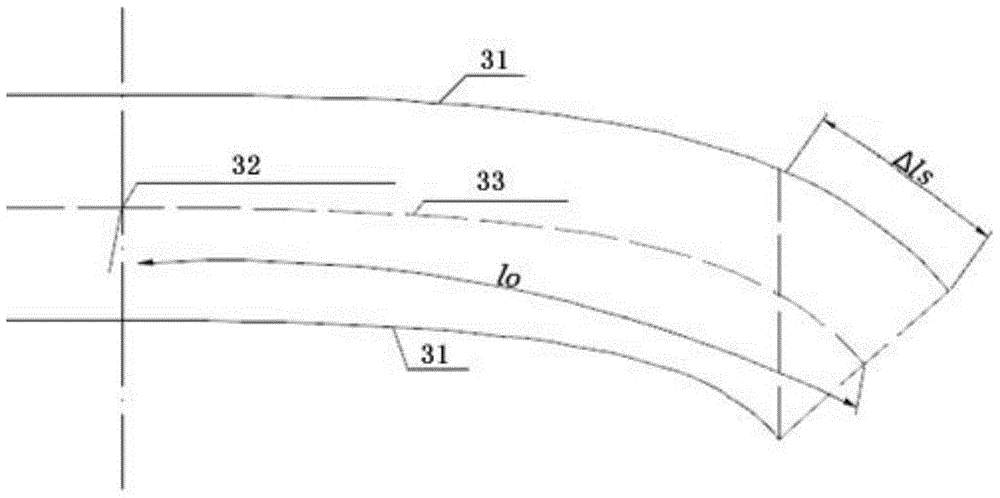

[0065] It is known that the symmetric transition curve turns left, R=300,l 0 =60, the total length of the curve L=207.742, the ZH point mileage is ZDK4+112.314, the starting mileage is ZDK4+104.5, the starting point misalignment is 35mm, the track center distance is 1508mm, the rail length is 25m, the sleeper spacing is 625mm, the sleeper To the left stock rail head 305mm, please configure the curved section rail row.

[0066] 1. Calculation of shortening amount:

[0067] ①Curve relaxation curve shortening amount:

[0068] ②Shortening of circular curve:

[0069] ③The total shortening of the curve: Δl=Δl S1 +Δl c +Δl S2 =151+441+151=743mm

[0070] 2. The configuration of the first auxiliary rail row:

[0071] ①The length of the rail row entry curve: starting point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com