Flange extension type column foot for a narrow flange steel column and construction technology of column foot

A construction technology and steel column technology, which can be used in infrastructure engineering, construction, etc., can solve the problems of too deep, too large bearing platform, uneconomical, etc., and achieve the advantages of reducing the embedded depth, improving economic benefits and improving integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

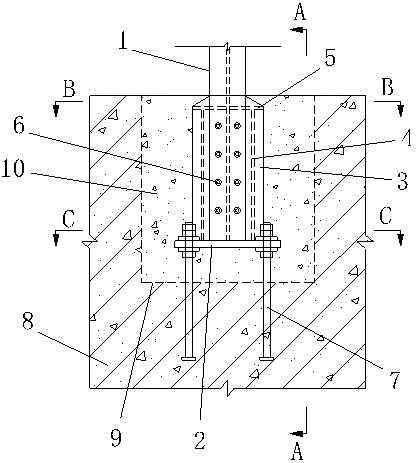

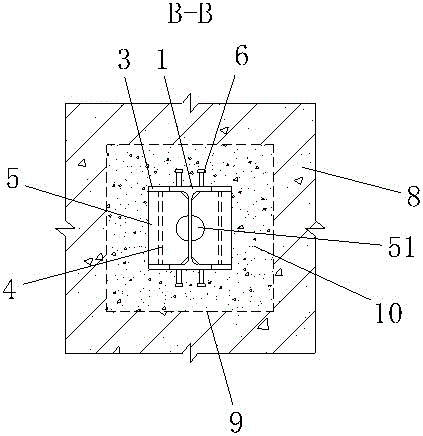

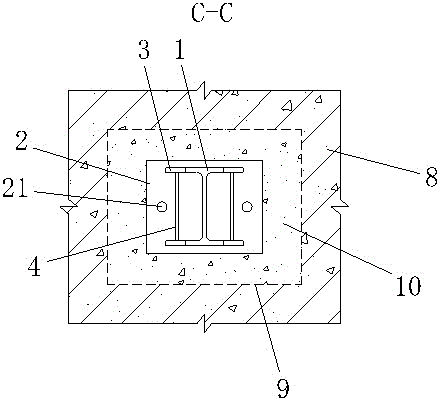

[0024] Embodiment one: if Figure 1~4 As shown, a narrow-flange steel column expanded airfoil column foot, the column foot is embedded in the reinforced concrete foundation, including the base plate 2 arranged on the bottom end surface of the H-shaped steel column 1, and two flanges respectively arranged on the two flanges of the steel column. The wing expansion plate 3 of the side wall, the wing expansion plate 3 is welded on the side wall of the flange through the groove full penetration weld, and is welded with the bottom plate 2, and the vertical expansion plate is welded between the two opposite wing expansion plates. Straight stiffener 4, the vertical stiffener 4 is parallel to the web of the steel column, and the flange, web, wing expansion plate 3, vertical stiffener 4 and the bottom plate together form a cavity, the cavity A horizontal stiffener 5 is provided at the top opening of the chamber, several pegs 6 are evenly distributed on the bottom of the outer walls of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com