A single-power two-way mobile traction drive system

A technology of traction transmission and two-way movement, which is applied in transmission devices, components with teeth, belts/chains/gears, etc. It can solve the problems of multi-metal materials and electric energy, occupy a large space, and complex structures, and achieve low production costs. , increase friction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

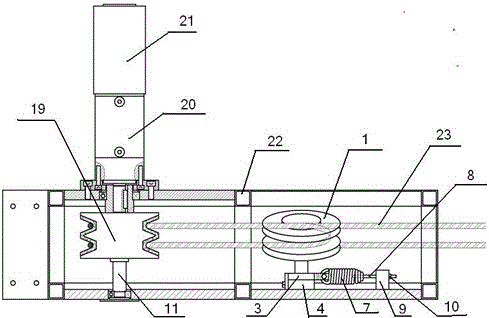

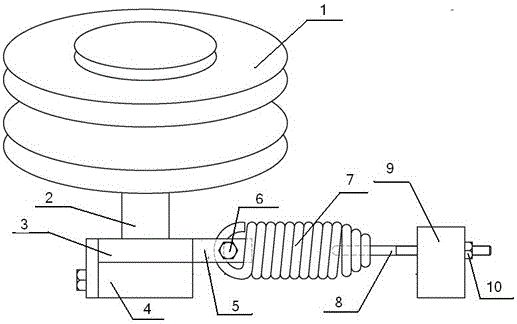

[0024] Such as figure 1 and Figure 5 As shown, a single-power two-way mobile traction transmission system of the present invention is composed of a power system 28, a bracket 22, a special-shaped rotating shaft 19, a tension adjustment mechanism, a pulley block and a traction rope 23;

[0025] The power system 28 is installed on the outside of the support 22 . The power system 28 includes two parts, the motor 21 and the reducer 20 .

[0026] The special-shaped rotating shaft 19 and the tension adjusting mechanism are installed inside the bracket 22 .

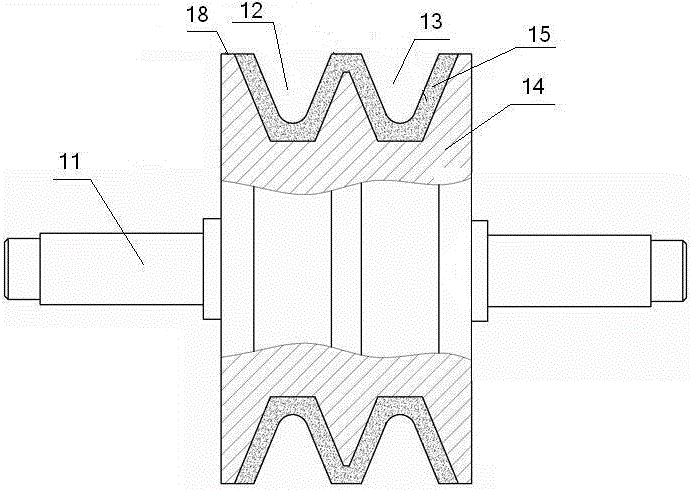

[0027] Such as image 3 and Figure 4 As shown, the special-shaped rotating shaft 19 includes a bearing 11 and a runner 14. There is a round hole 17 at the center of the runner 14, and the bearing 11 is installed at the round hole 17 of the runner 14; the rim of the runner 14 The surface of 18 is formed by a first groove 12 and a second groove 13 in a "W" shape, and the surface of the first groove 12 and the second groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com