Low-noise water inlet valve body and method for realizing mute when anti-siphon water inlet valve enters water

A water inlet valve, low-noise technology, applied in the valve's device for absorbing fluid energy, valve details, valve device, etc., can solve the problems that the water inlet valve is difficult to meet the requirements of ENISO3822, it is difficult to find the water inlet valve, and the water is urgent, etc. Achieve the effects of simple structure, low cost and slow water flow of the water inlet valve body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

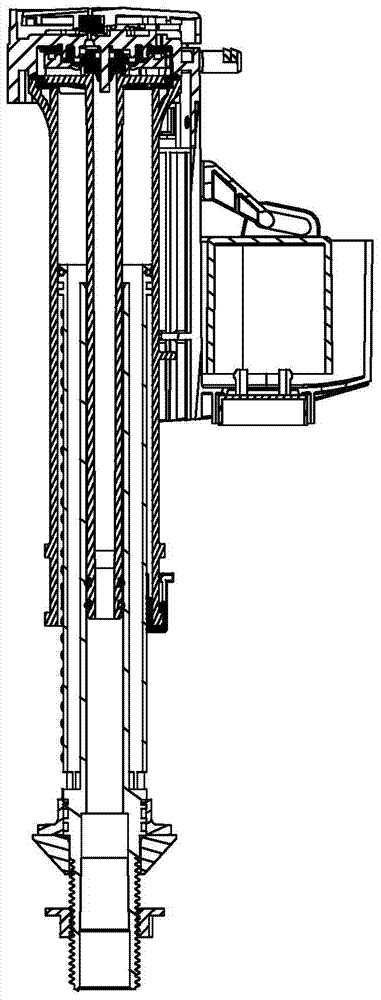

[0077] Such as Figure 1 to Figure 8 The shown low-noise water inlet valve body includes a water inlet valve body 100, a lower casing 200, and an upper casing 300. The lower casing 200 is connected to the water inlet valve body 100 to supply water to the water inlet valve body 100. The upper casing 300 is set between the main body 100 of the water inlet valve and the lower casing 200. The main body of the water inlet valve 100, the lower casing 200 and the upper casing 300 together form a water outlet pipe; the main body of the water inlet valve 100 is higher than the water inlet valve. The position of the highest water level is provided with an air vent 400, and the liquid level in the water inlet valve is directly connected to the atmosphere through the air vent 400 to realize anti-siphon; the water outlet channel 105 of the water inlet valve includes a main waterway 101, several auxiliary waterways 102, the main waterway 101 is directly connected with the water inlet channe...

Embodiment 2

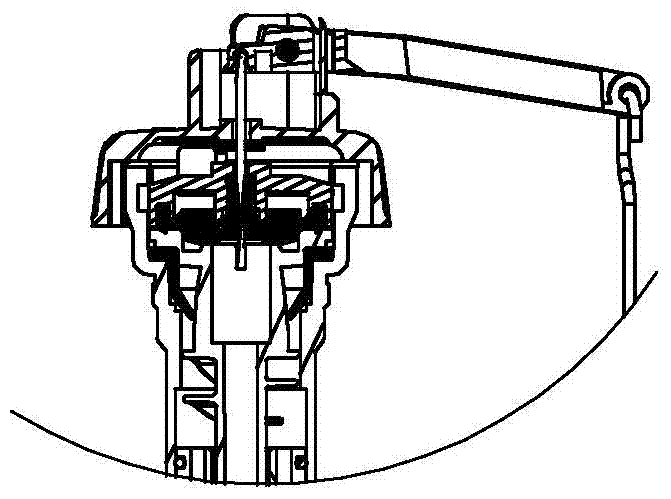

[0085] Such as Figures 16 to 21 The shown low-noise water inlet valve body includes a water inlet valve body 100, a lower casing 200, and an upper casing 300. The lower casing 200 is connected to the water inlet valve body 100 to supply water to the water inlet valve body 100. The upper casing 300 is set between the main body 100 of the water inlet valve and the lower casing 200. The main body of the water inlet valve 100, the lower casing 200 and the upper casing 300 together form a water outlet pipe; the main body of the water inlet valve 100 is higher than the water inlet valve. The position of the highest water level is provided with an air vent 400, and the liquid level in the water inlet valve is directly connected to the atmosphere through the air vent 400 to realize anti-siphon; the water outlet channel 105 of the water inlet valve includes a main waterway 101, several auxiliary waterways 102, the main waterway 101 is directly connected with the water inlet channel 10...

Embodiment 3

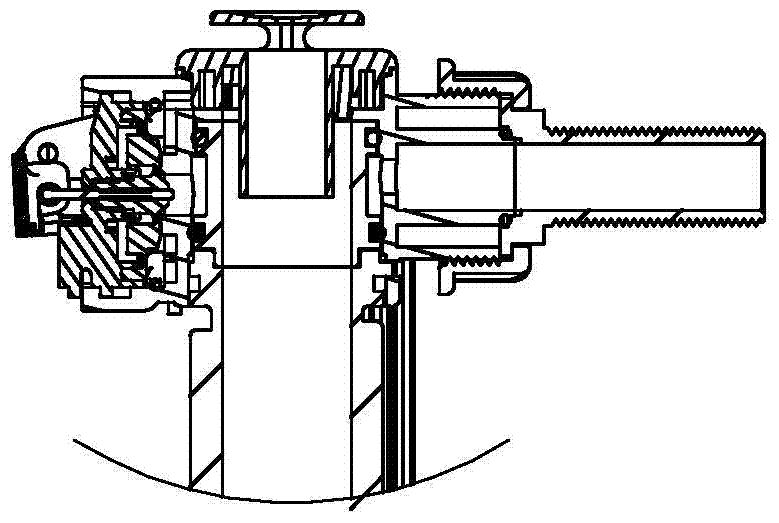

[0093] Such as Figures 27 to 33 The shown low-noise water inlet valve body includes a water inlet valve body 100, a lower casing 200, and an upper casing 300. The lower casing 200 is connected to the water inlet valve body 100 to supply water to the water inlet valve body 100. The upper casing 300 is set between the main body 100 of the water inlet valve and the lower casing 200. The main body of the water inlet valve 100, the lower casing 200 and the upper casing 300 together form a water outlet pipe; the main body of the water inlet valve 100 is higher than the water inlet valve. The position of the highest water level is provided with an air vent 400, and the liquid level in the water inlet valve is directly connected to the atmosphere through the air vent 400 to realize anti-siphon; the water outlet channel 105 of the water inlet valve includes a main waterway 101, several auxiliary waterways 102, the main waterway 101 is directly connected with the water inlet channel 103,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com