An ultrasonic motor intelligent detection device for missing edges of bamboo chips

An ultrasonic motor, intelligent detection technology, applied in the direction of using a device that measures the time required to move a certain distance, can solve the problems of incompetence, low efficiency, missed detection, etc., and achieve the effect of efficient and stable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0025] A kind of specific embodiment of the present invention is as follows:

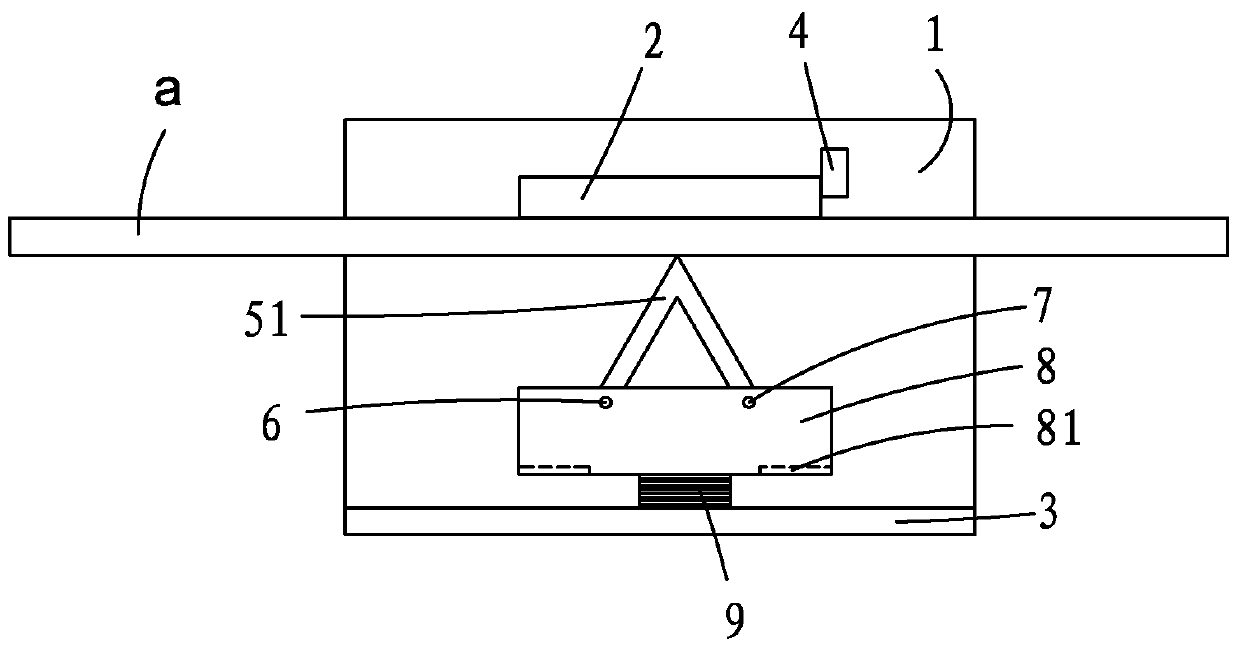

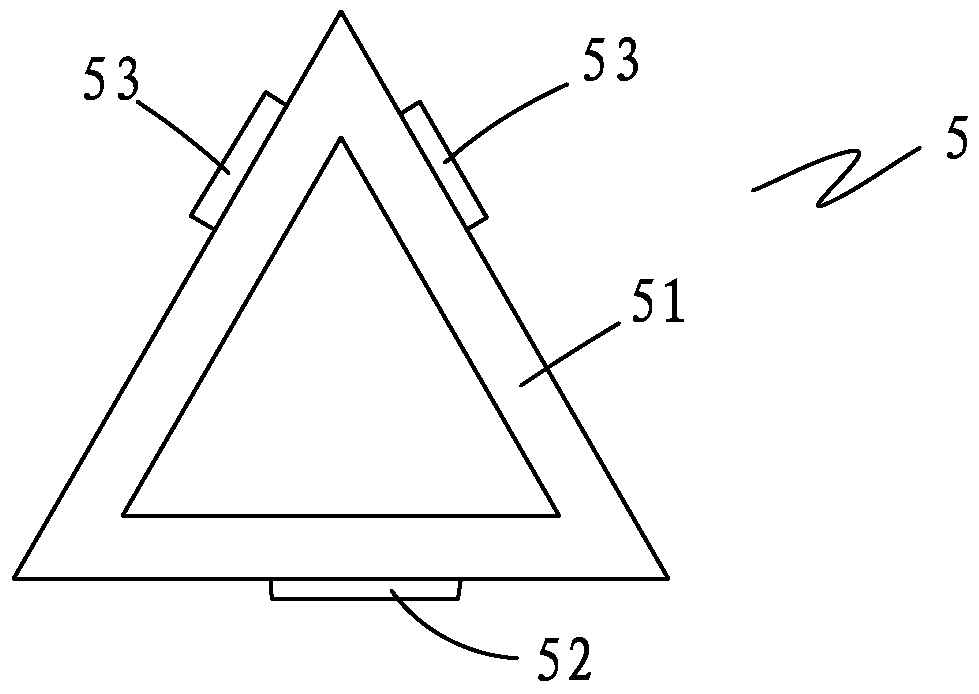

[0026] Such as figure 1 and 2 As shown, the device of the present invention is an integrated device for automatic detection of bamboo chip conveying and automatic detection of missing edges. The device 4 is composed. (this example is a triangle, also can be rectangle or circle etc.) ultrasonic motor 5 provides to drive bamboo slice to move forward, because (this example is triangle, also can be rectangle or circle etc.) the drive of ultrasonic motor is micron level , because the first piezoelectric ceramic 52 and the second piezoelectric ceramic 53 make the top of the symmetrical structure (triangular in this example, also can be rectangular or circular, etc.) the stator produce two vertical and horizontal motions (that is, the ultrasonic motor 5 The driving point produces an elliptical motion), if its structure is symmetrical, the resonant frequencies of its horizontal and vertical motions can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com