Patents

Literature

50results about How to "Convenient manual inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

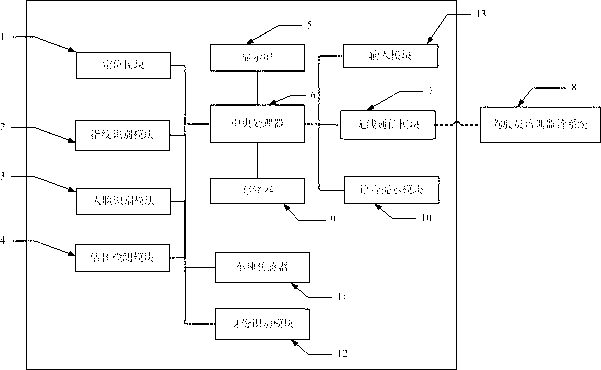

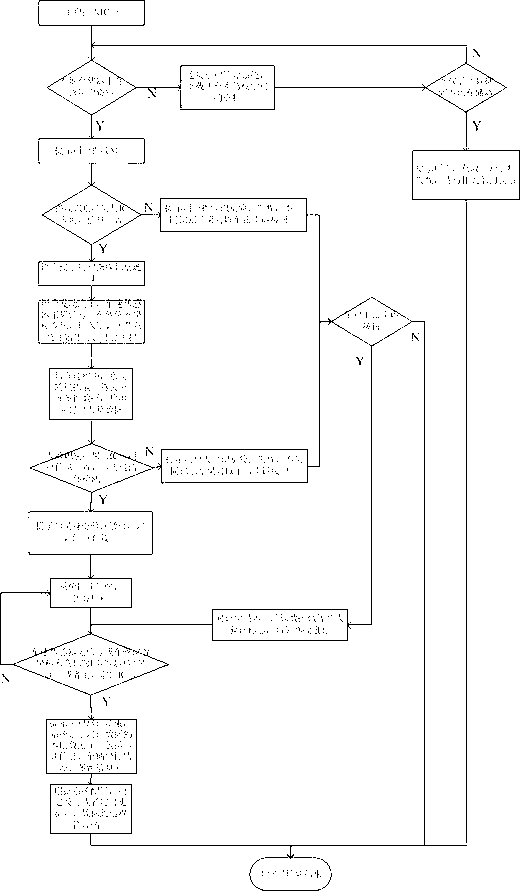

Anti-cheating driver training recorder

InactiveCN103106703ATimely identity verificationPrevent fraudulent card swipingRegistering/indicating working of vehiclesIdentity recognitionEmbedded system

The invention relates to a vehicle-mounted device, and in particular relates to an anti-cheating driver training recorder capable of combining automatic identification and manual intervention. A central processing unit (CPU) of the anti-cheating driver training recorder is connected with a locating module, a fingerprint identification module, a face recognition module, an in-vivo detection module, an identity recognition module and a memory respectively; and the CPU is connected with a driver training supervisory system by a wireless communication module. The anti-cheating driver training recorder effectively solves various cheating problems in the motor vehicle driver training, thus guaranteeing the training quality and effectively monitoring the motor vehicle driver training.

Owner:张平

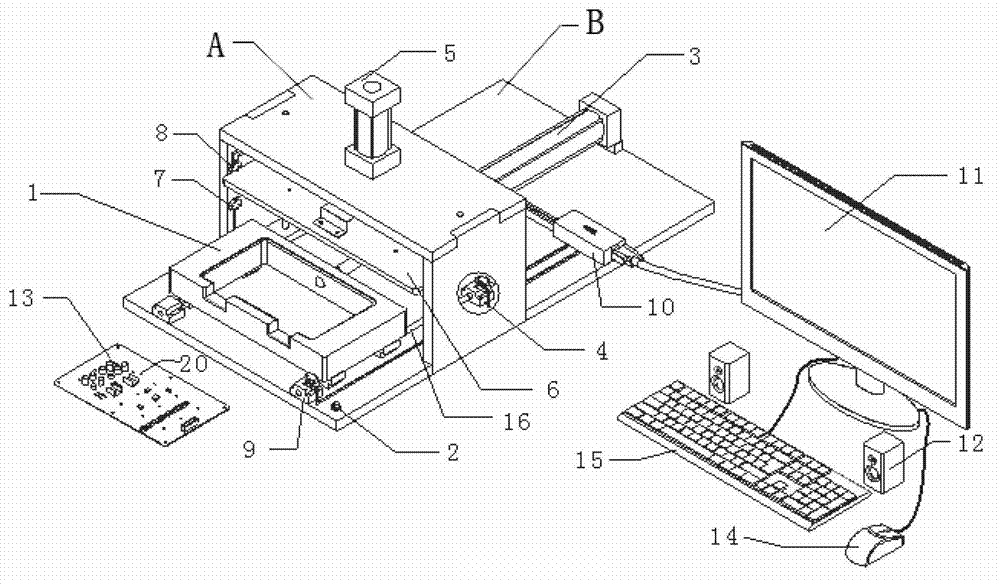

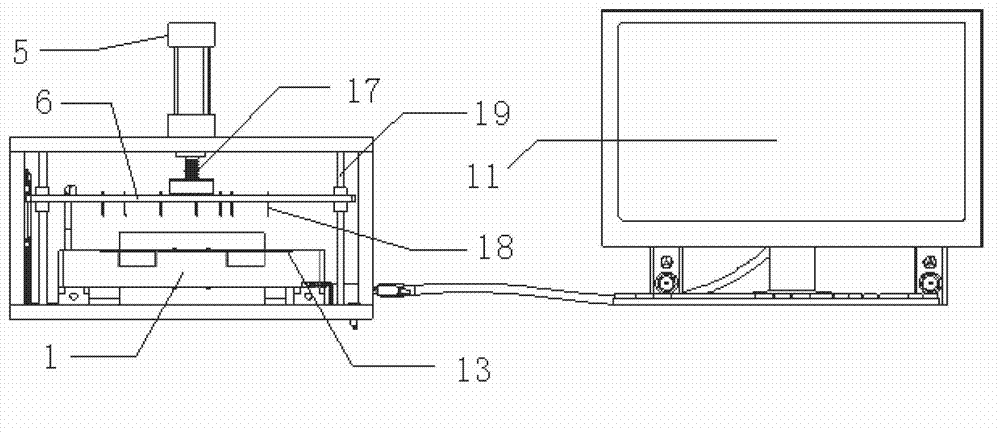

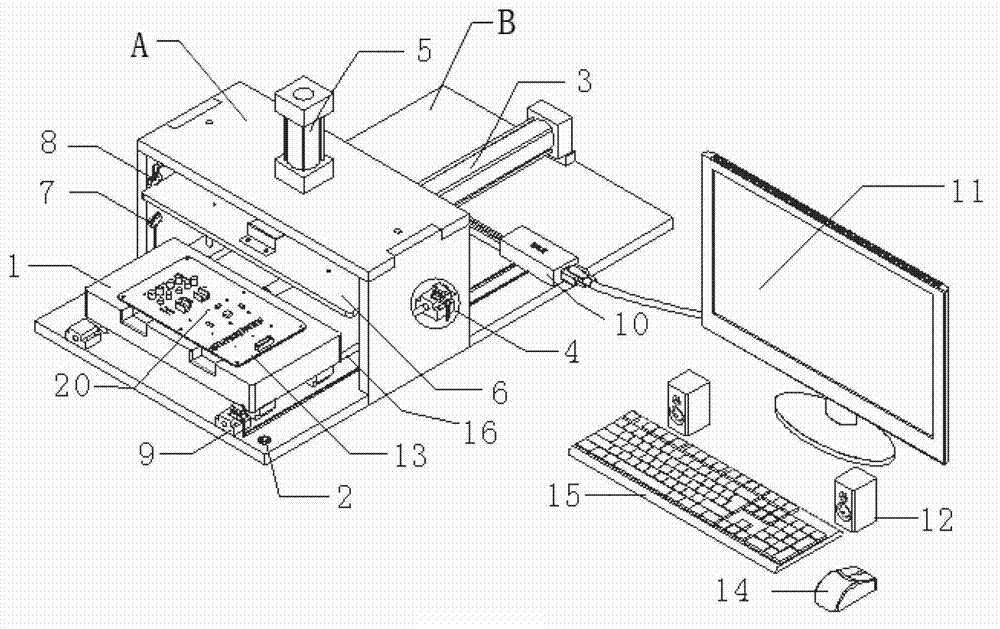

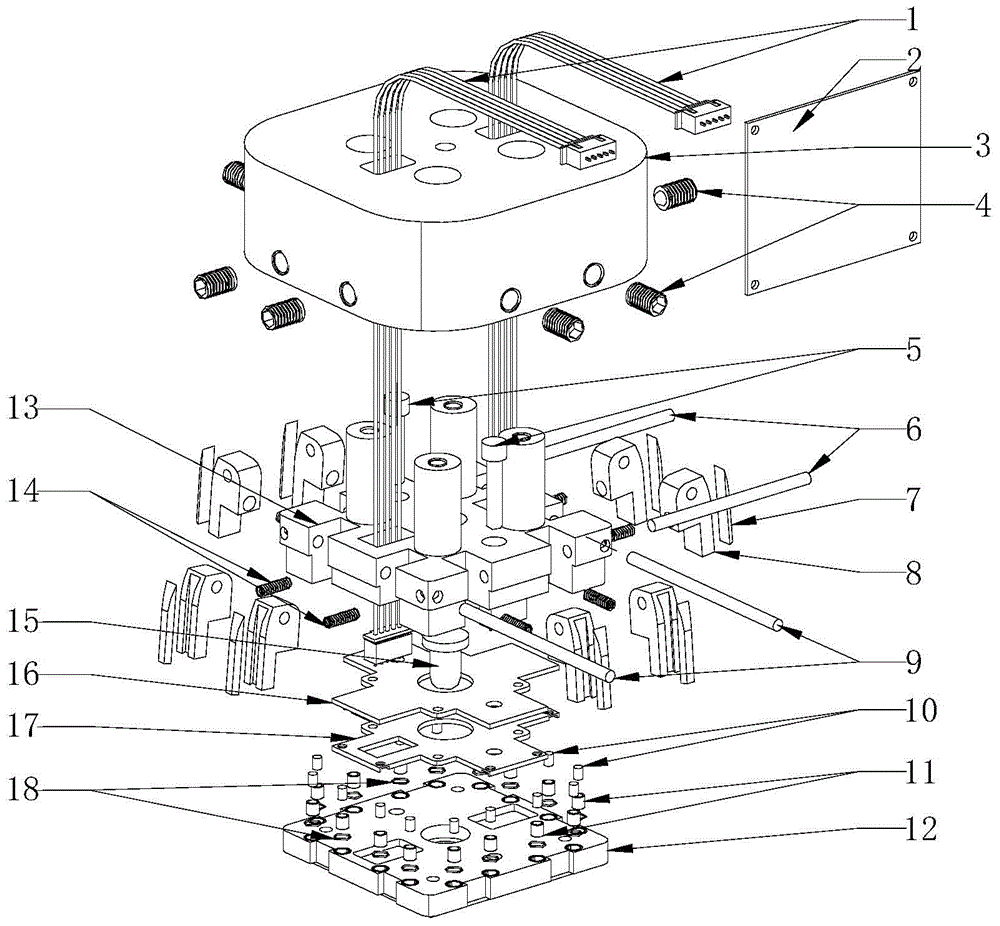

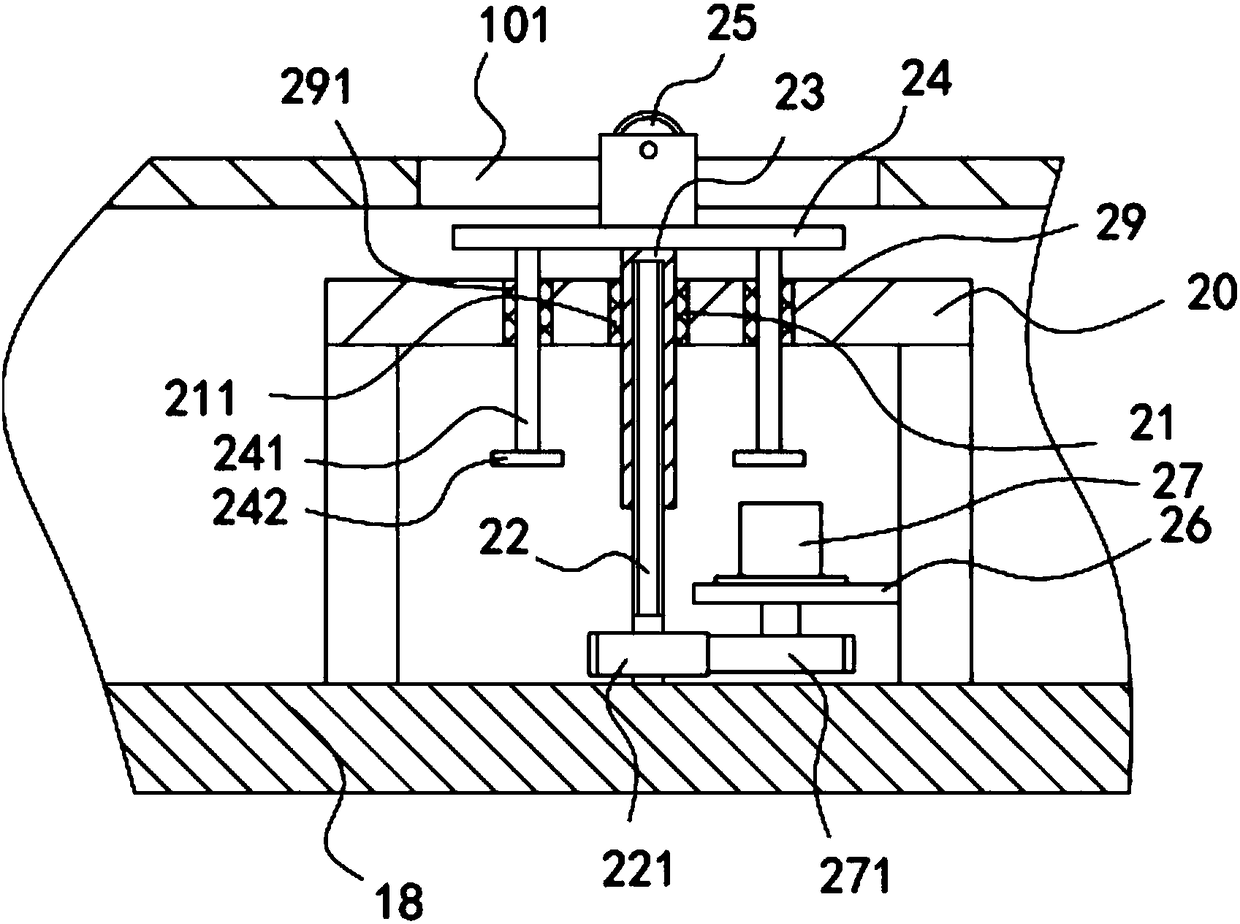

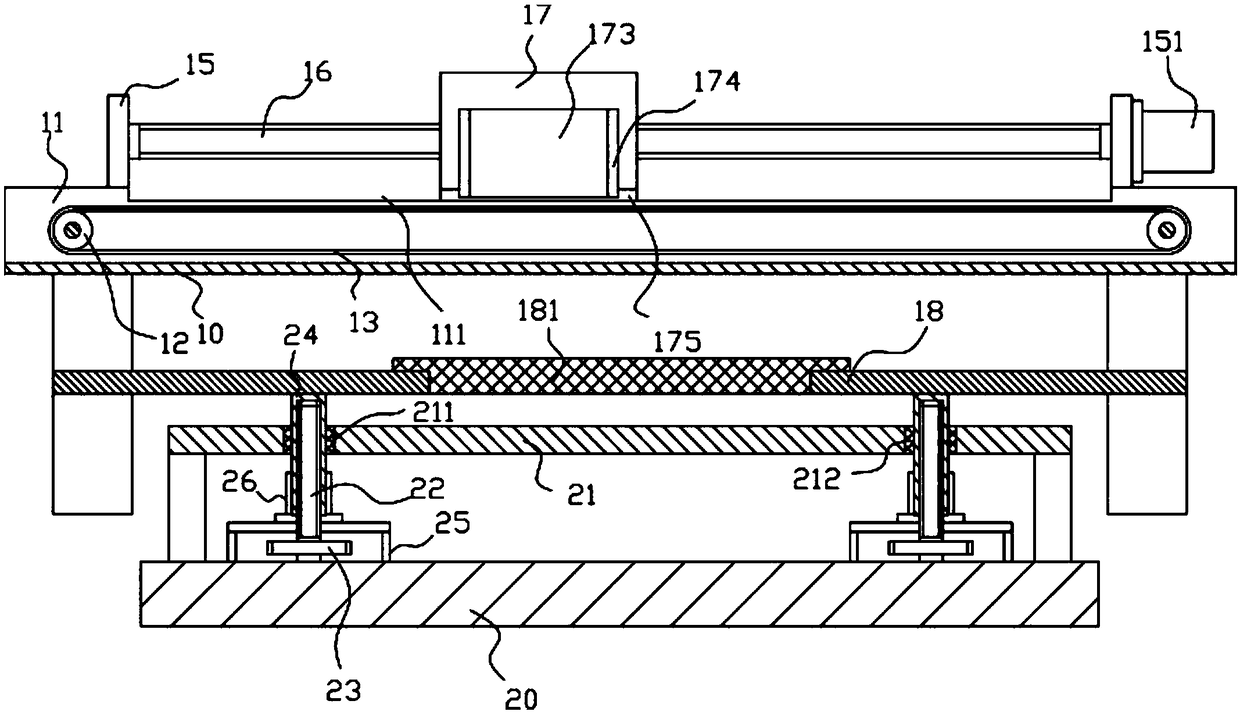

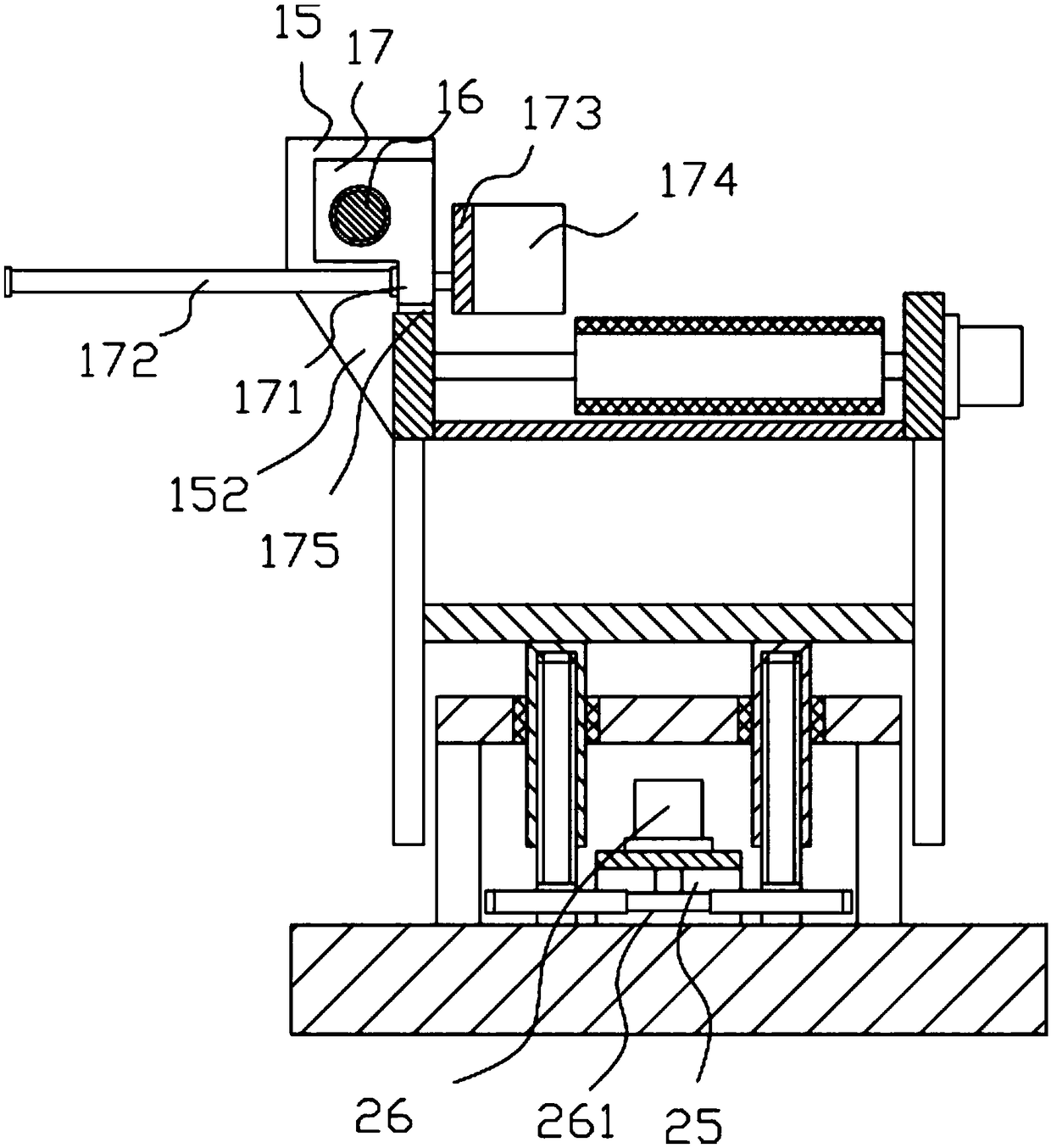

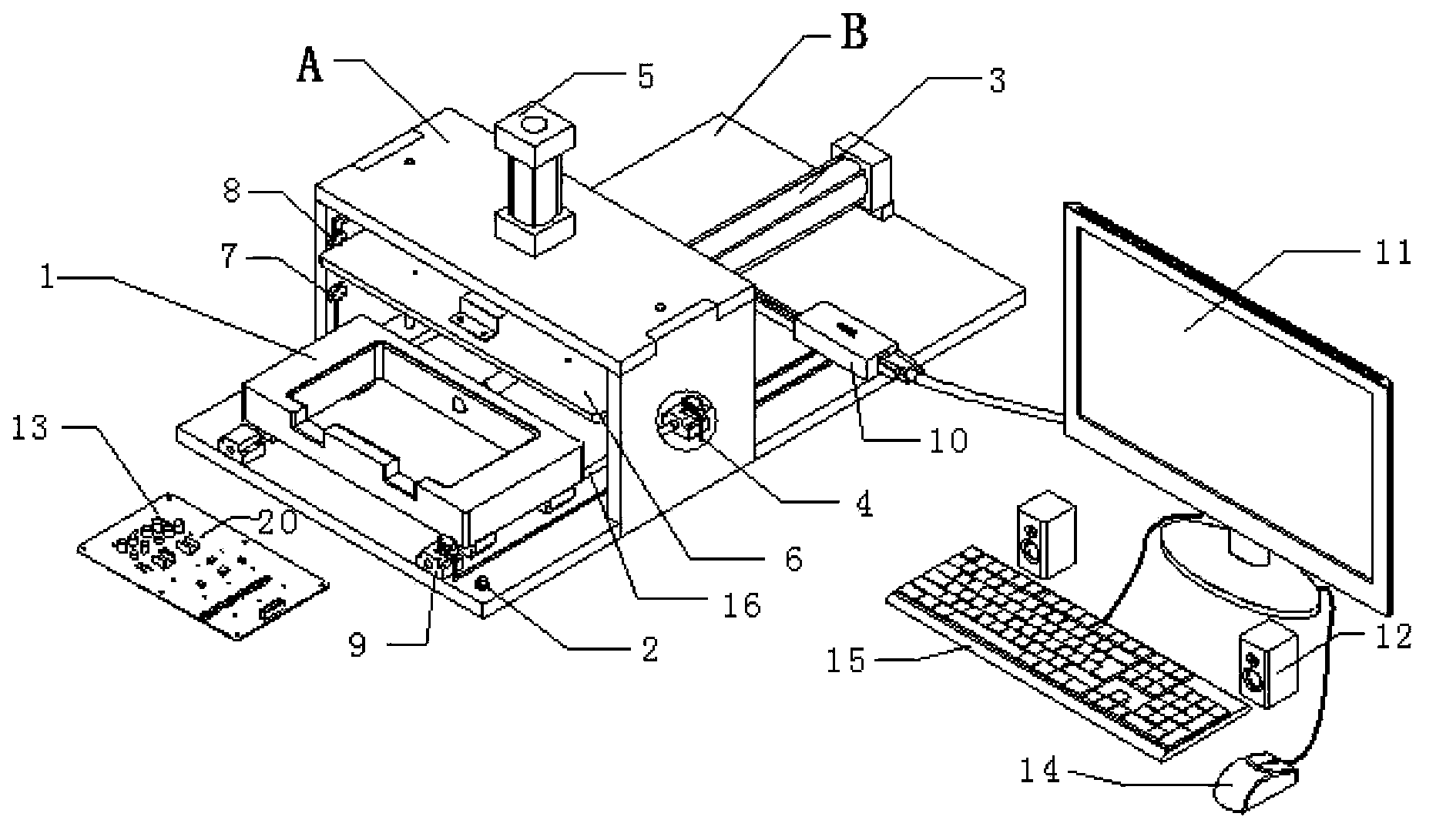

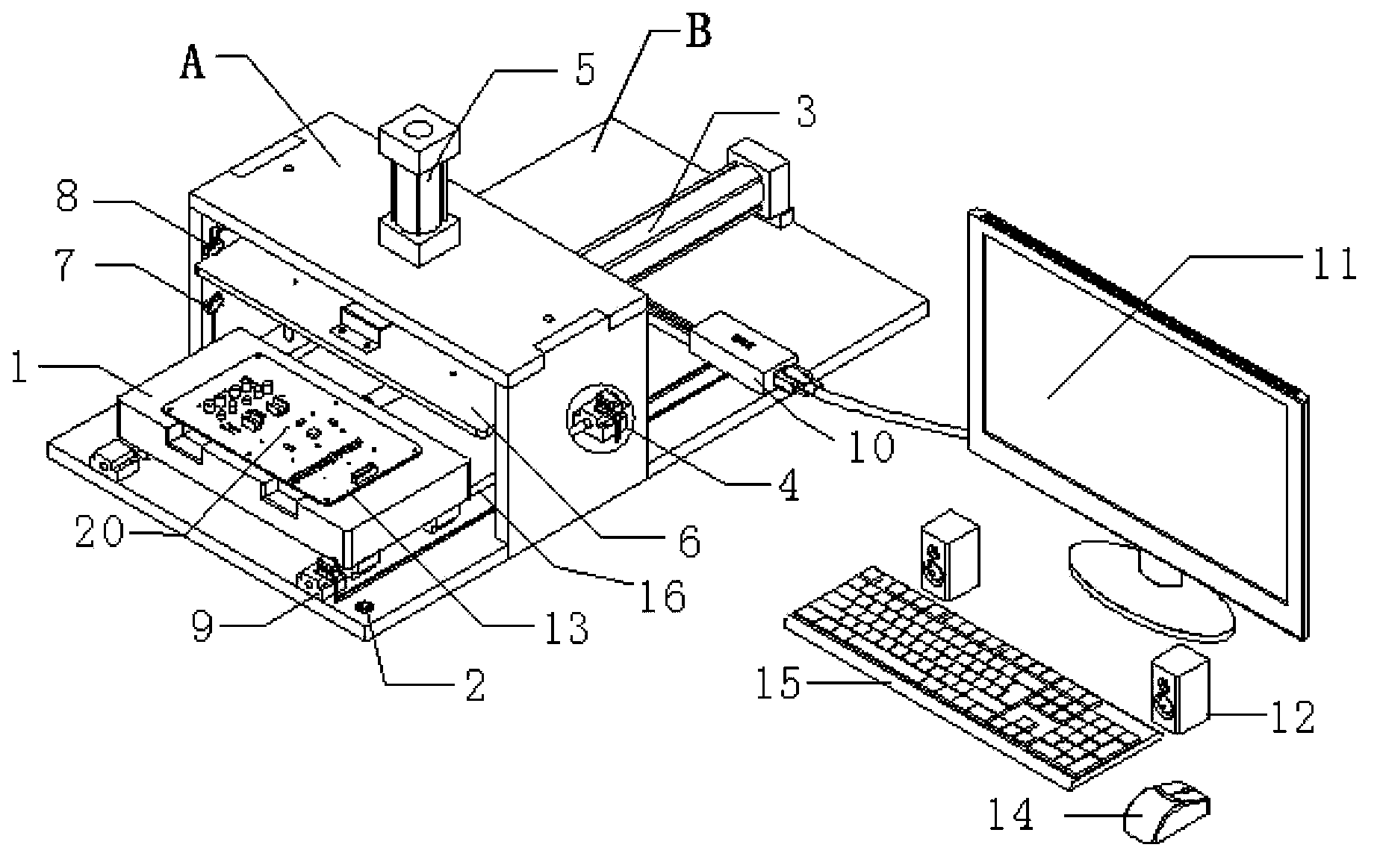

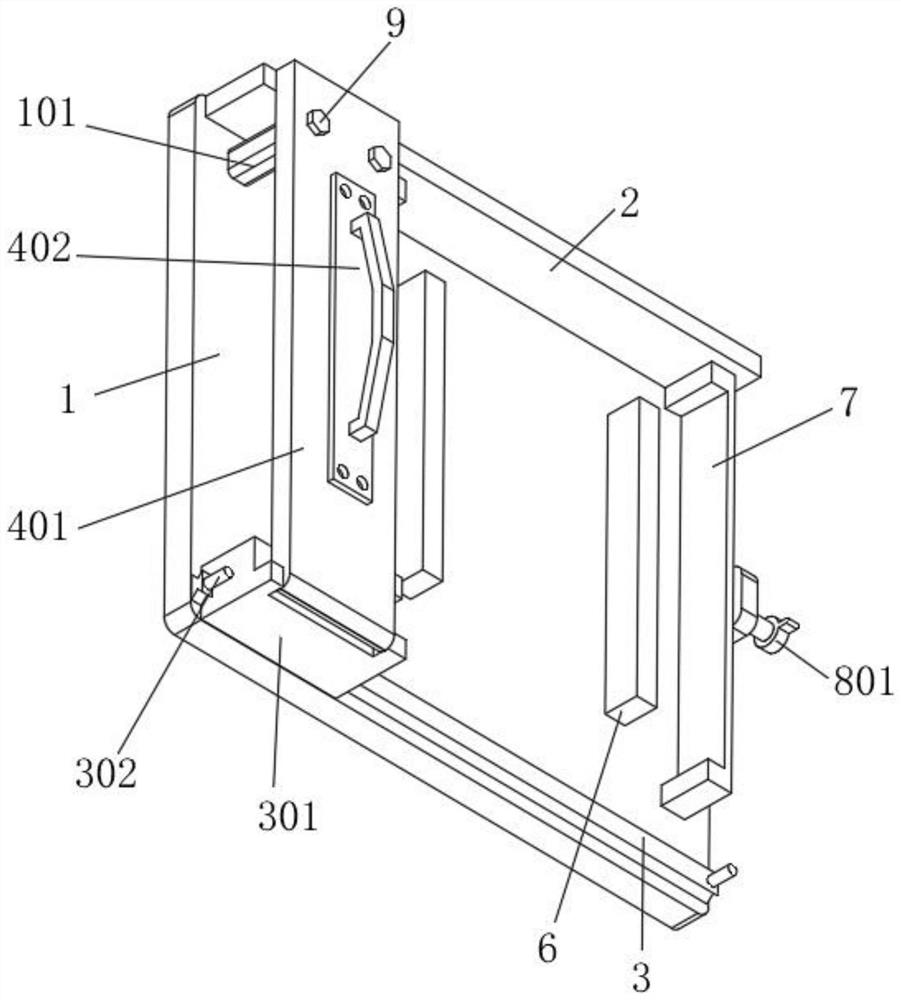

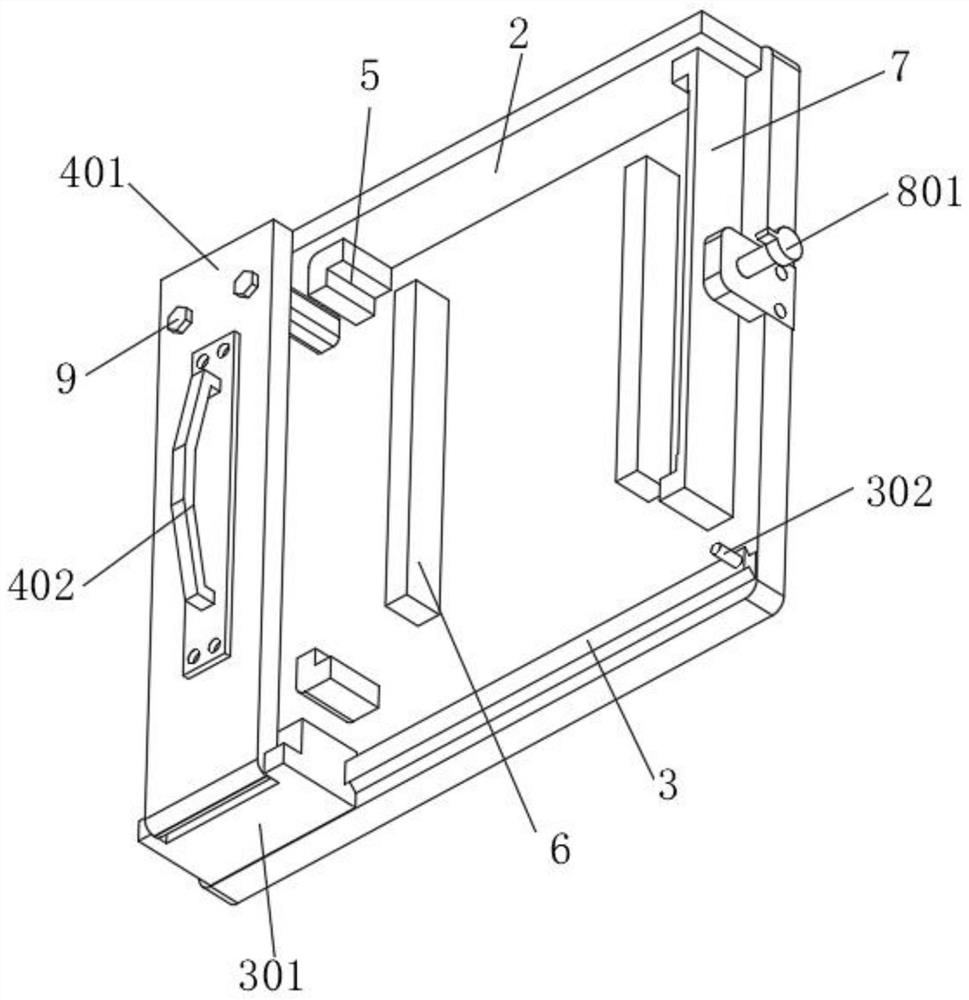

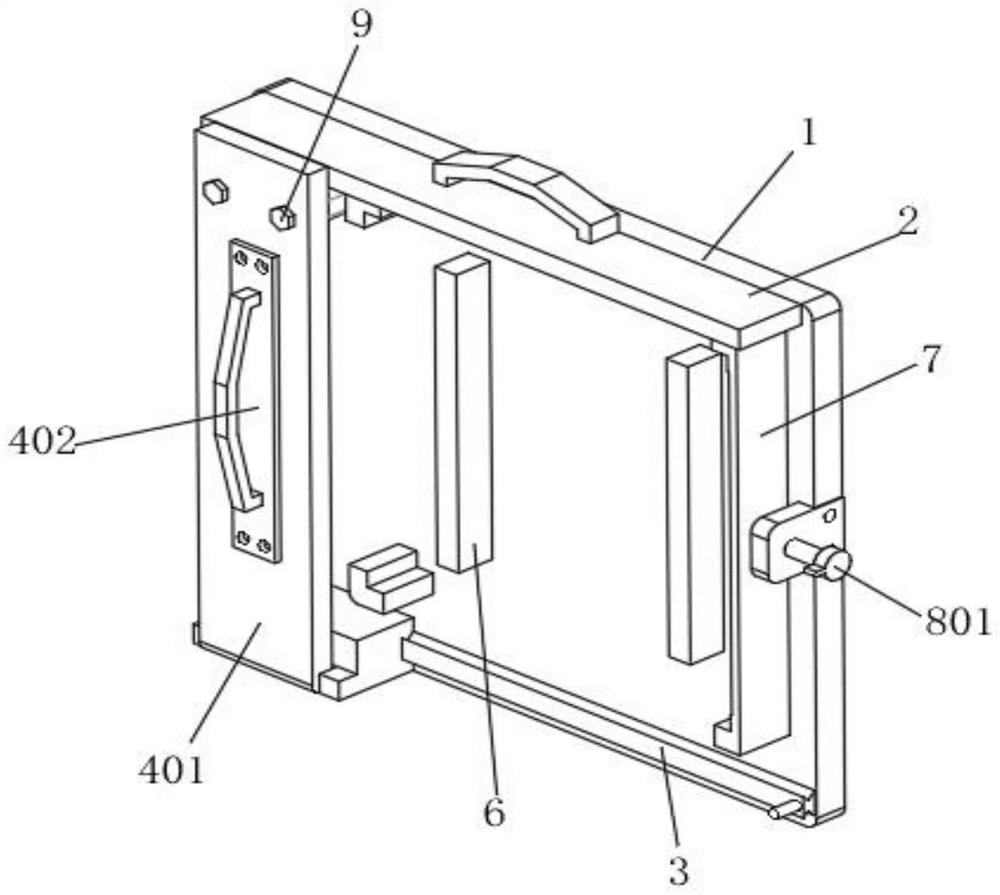

Detection device for detecting circuit board

ActiveCN102890233AImprove work efficiencyGood detachmentElectronic circuit testingEngineeringElectrical and Electronics engineering

The invention discloses a detection device for detecting a circuit board. The detection device comprises a base, a processor and a signal output unit, wherein a circuit board placement seat and a detection mechanism are arranged on the base; when the circuit board is placed on the circuit board placement seat, the detection mechanism moves relative to the circuit board placement seat, and is contacted with a detection point of the circuit board and used for detecting the circuit board; the detection mechanism sends the detection information of the circuit board to the processor; the processor forwards the received signal to the signal output unit; and the signal output unit outputs a detection result of the circuit board according to the received information. The invention aims to provide the detection device capable of automatically detecting the circuit board.

Owner:GUANGZHOU CANLEAD ENERGY TECH CO LTD

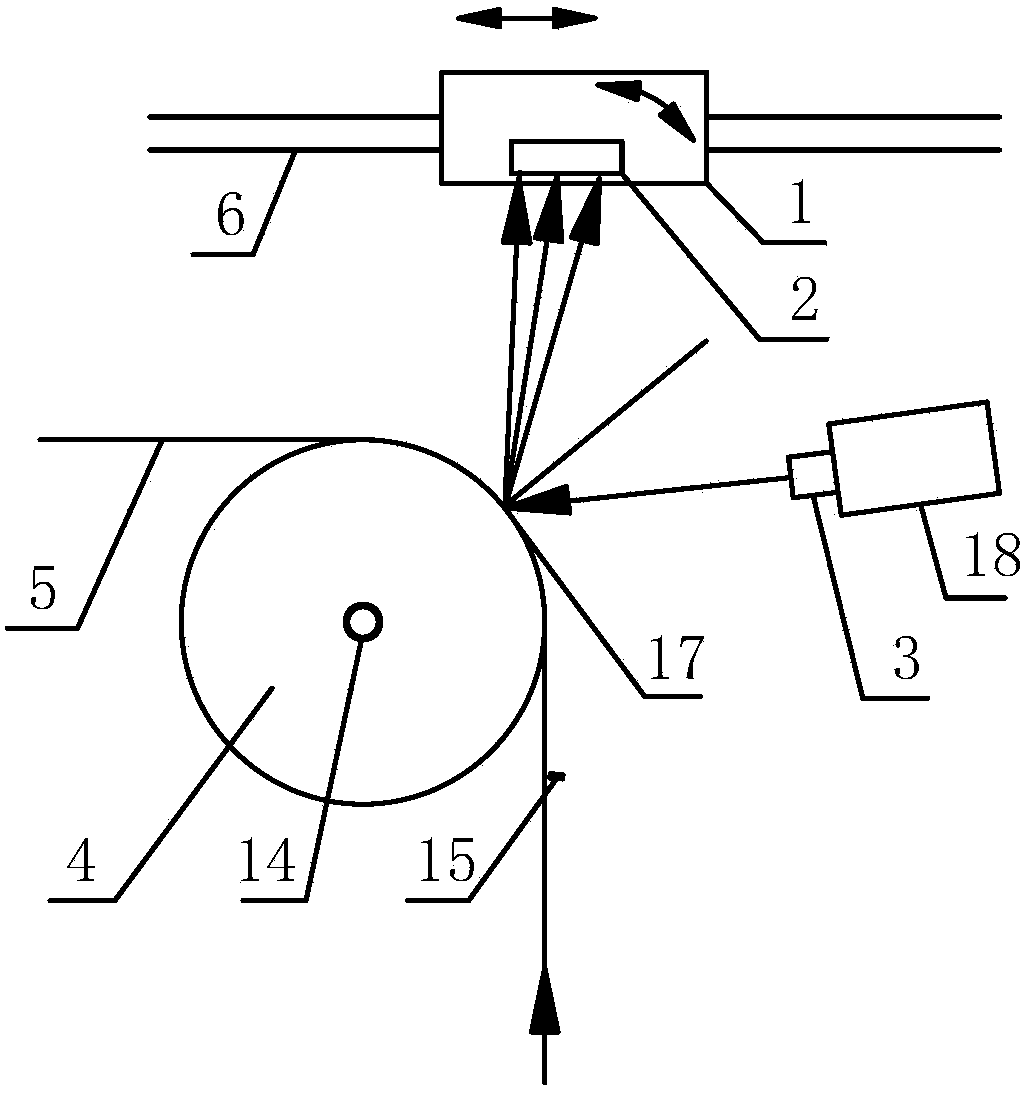

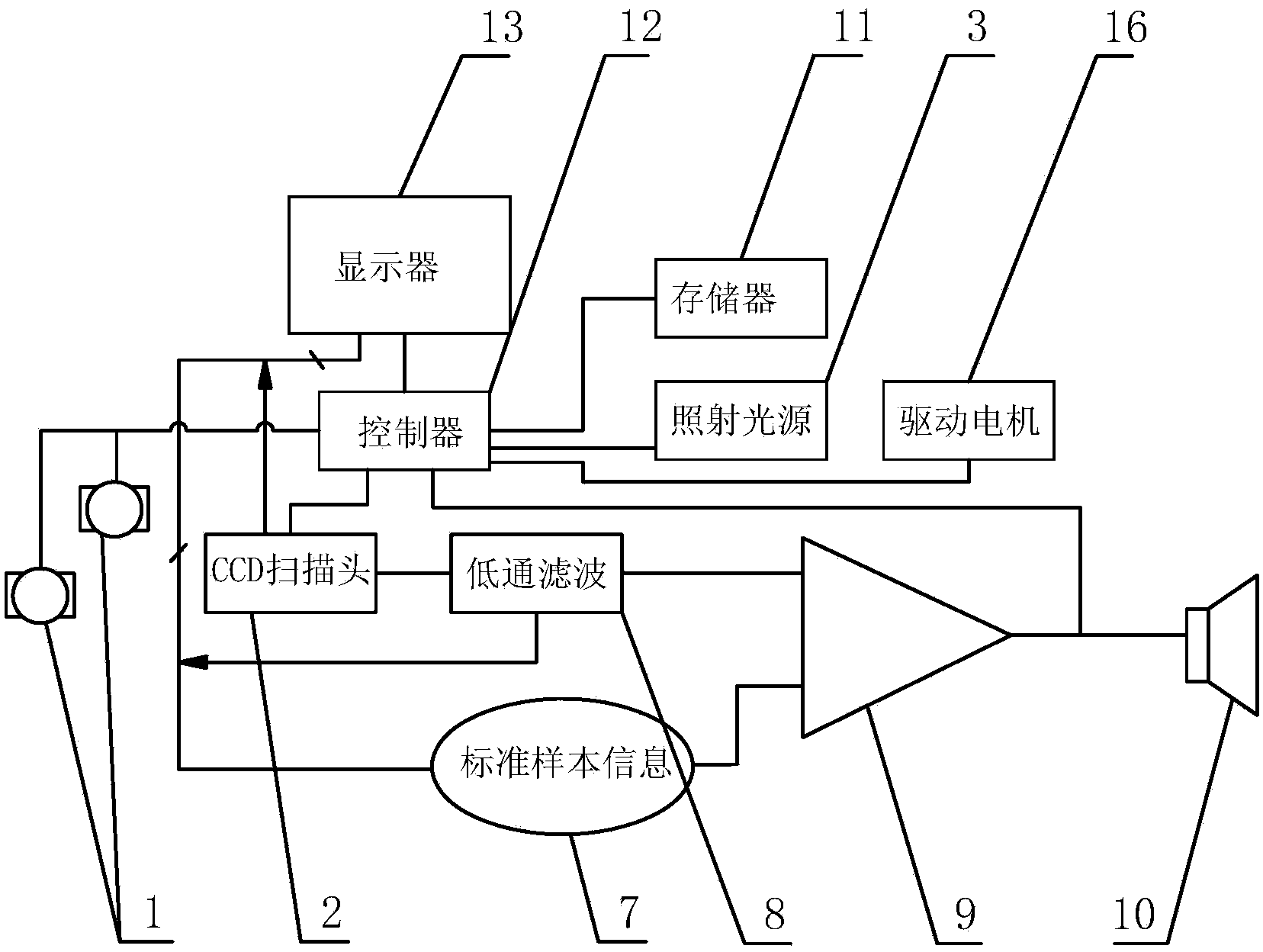

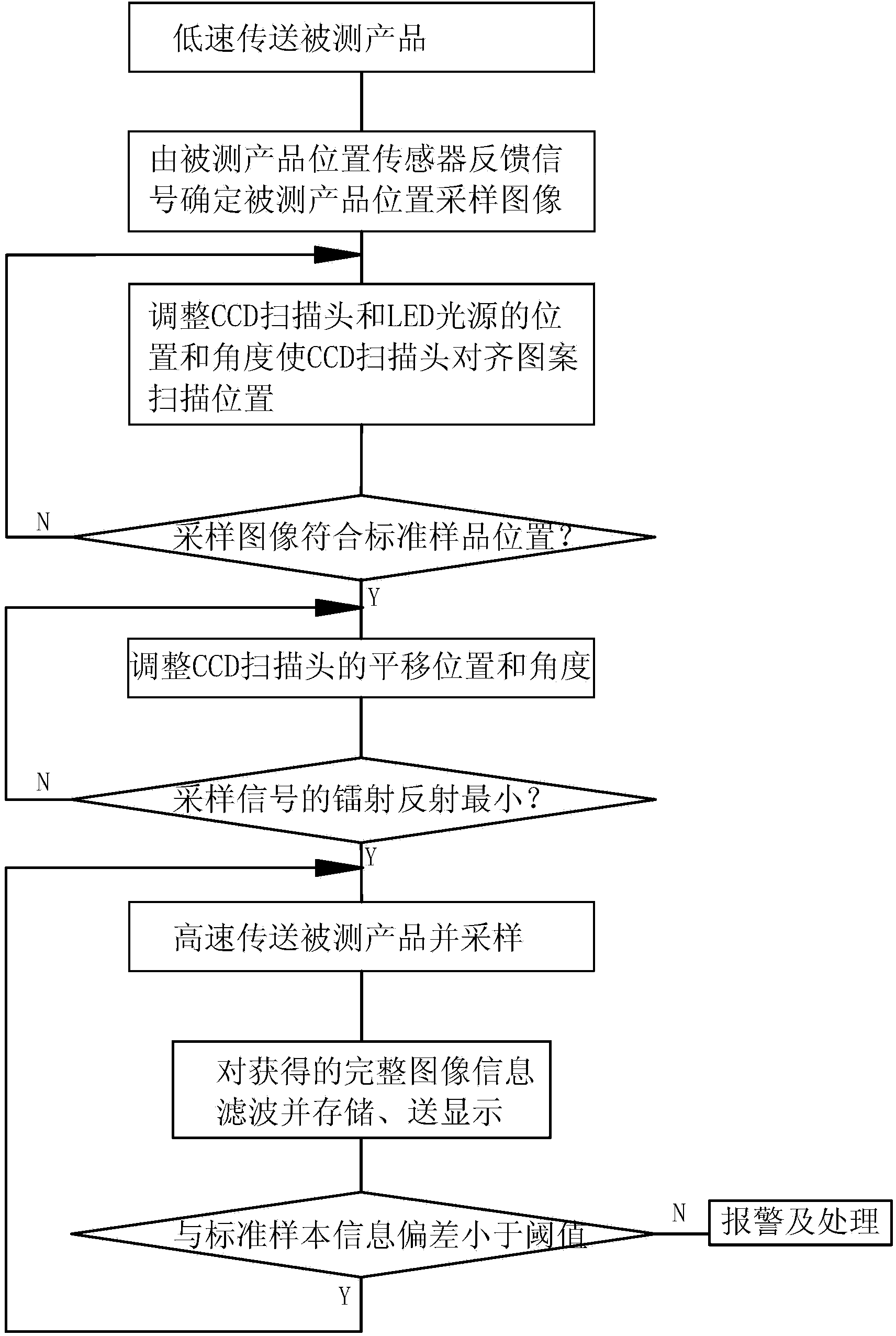

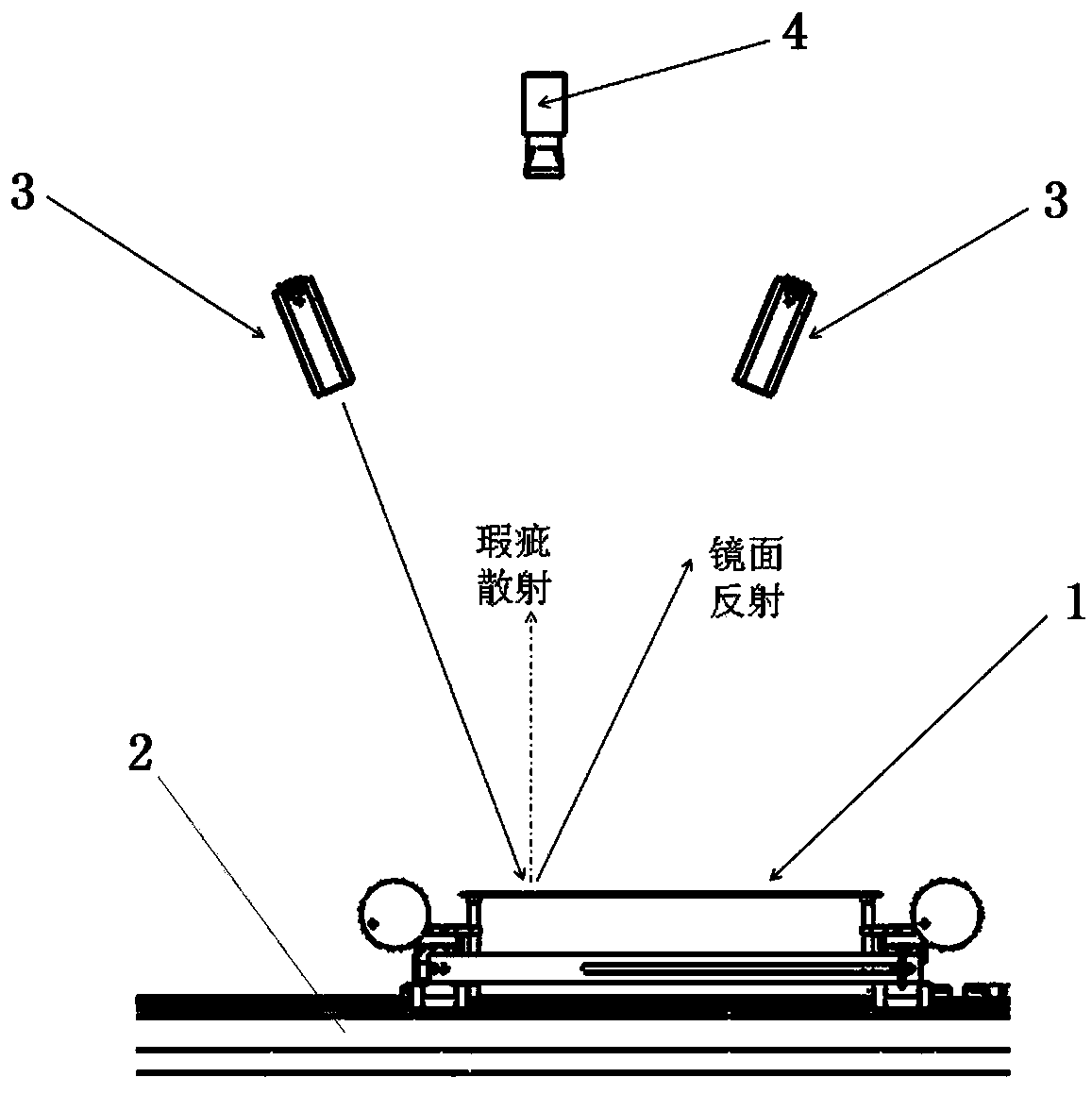

System and method for detecting quality of holographic shading laser packing material printed matter

ActiveCN103822926ARealize detectionSolve the problem of printing quality inspectionMaterial analysis by optical meansProduction lineOptoelectronics

The invention discloses a system and a method for detecting quality of a holographic shading laser packing material printed matter. The system and the method are used for detecting the apparent quality of the laser shading printed matter at an unfixed position. An LED light source and a CCD scan head are asymmetrically arranged on the outer side of a transfer roller for supporting holographic laser shading printed sheet; laser-resistant photic driving mechanisms at least can do linear movement in a plane passing through a detecting point and perpendicular to the axis of the transfer roller and autorotate by revolving the center shaft, are used for adjusting the CCD scan head, and enable the CCD scan head to collect a clear pattern of the printed matter through reflected lights of the LED light source and keep away reflected lights of the laser shading. Aiming at the finished product with the laser shading appearing at the unfixed position in the printed matters, a simple, convenient and effective detection scheme is provided, and the detection of the printing quality can be realized through lowcost transformation of a conventional quality detection system on the production line of the printed matters.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

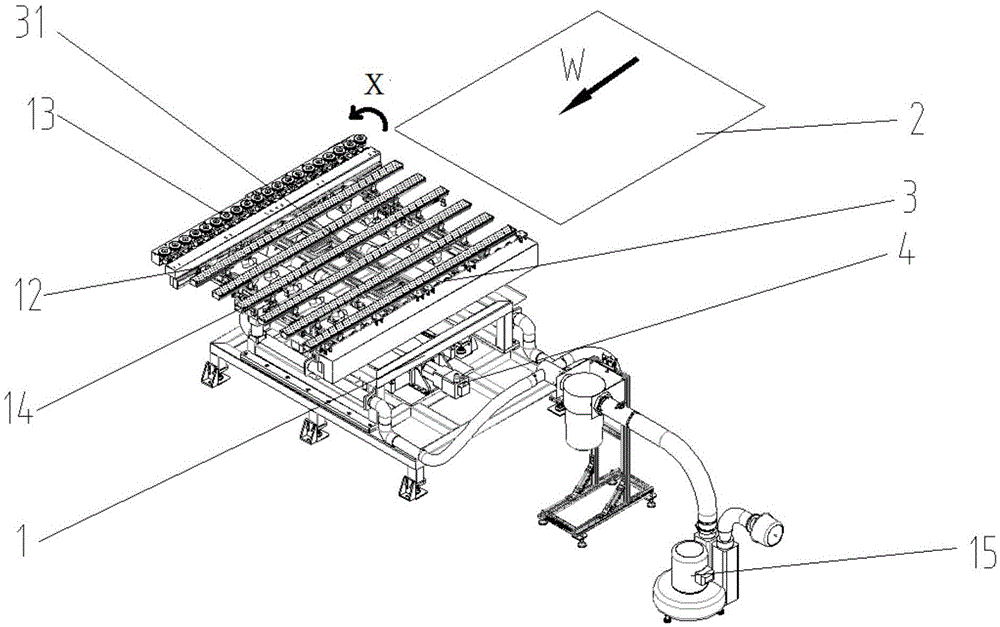

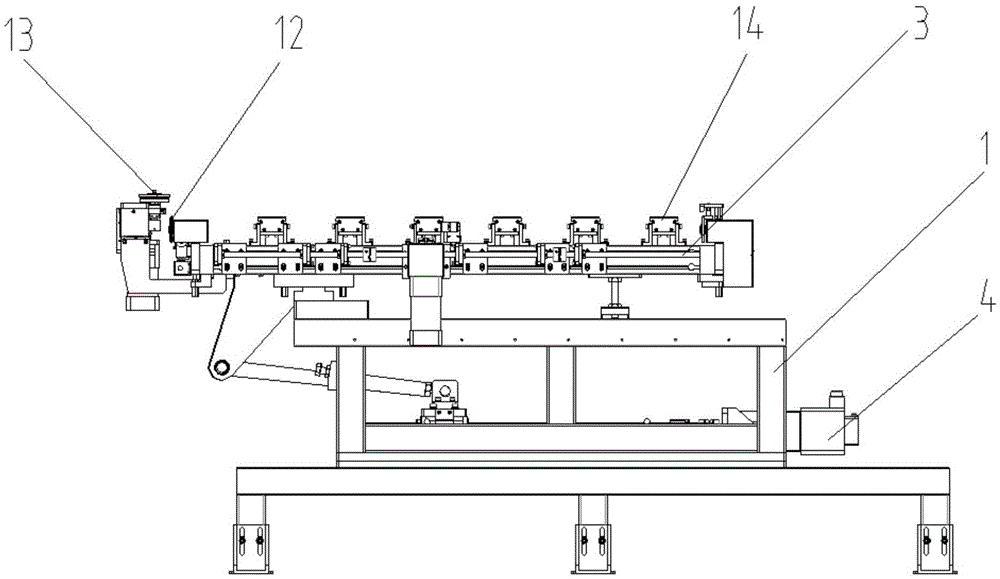

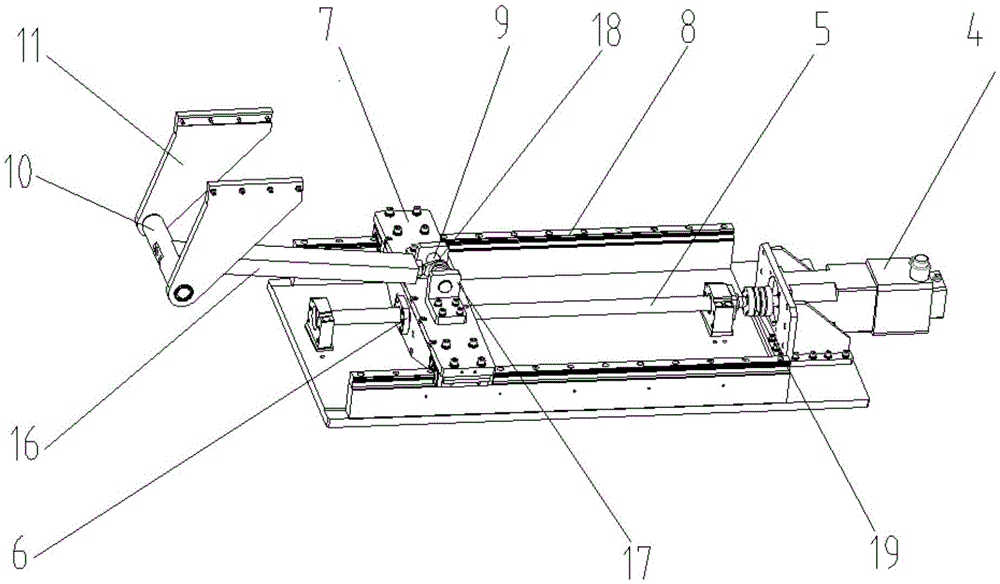

Glass substrate delivery equipment

InactiveCN105600445AImprove qualityReduce the impact of return airConveyorsCharge manipulationEngineeringLoad carrying

Owner:TUNGHSU TECH GRP CO LTD +1

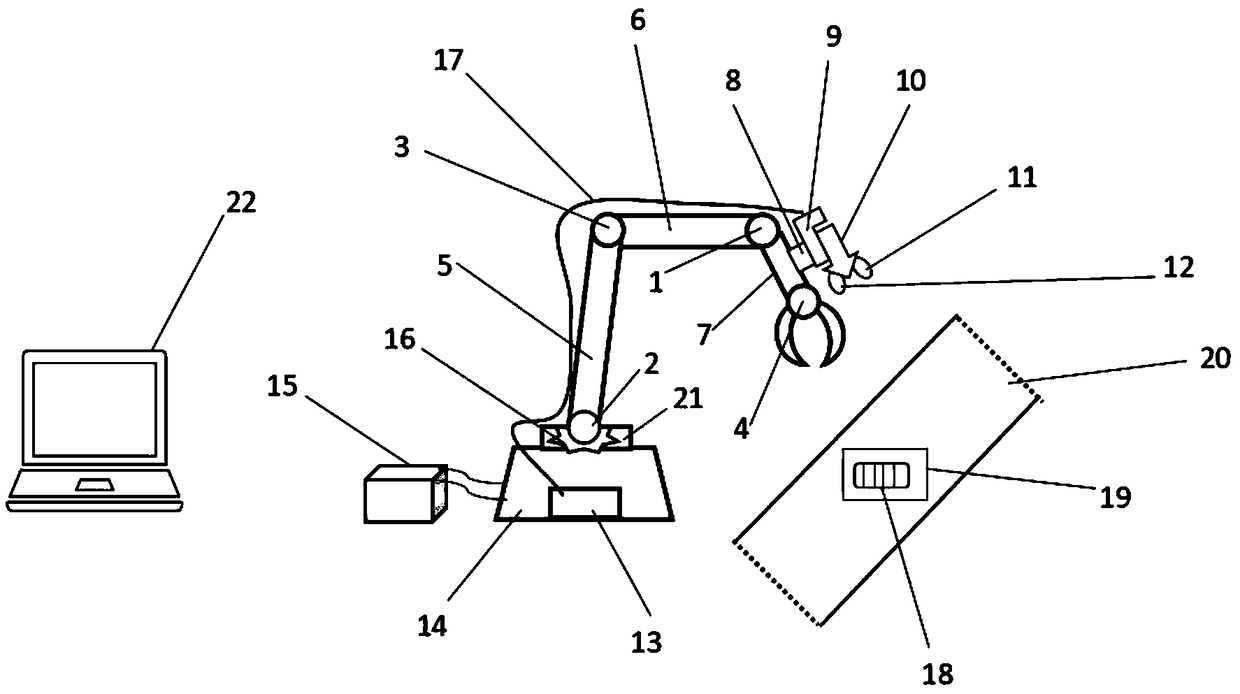

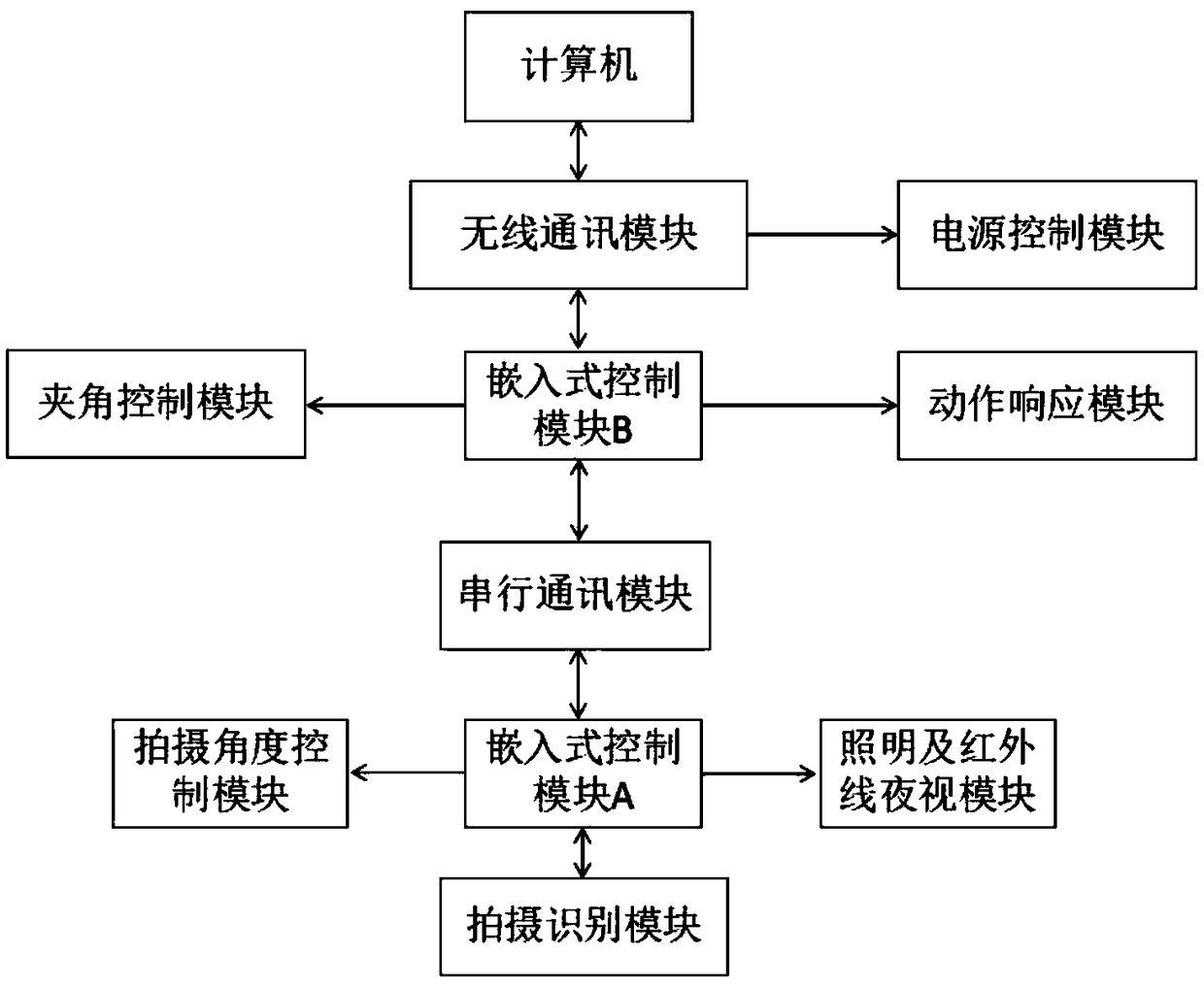

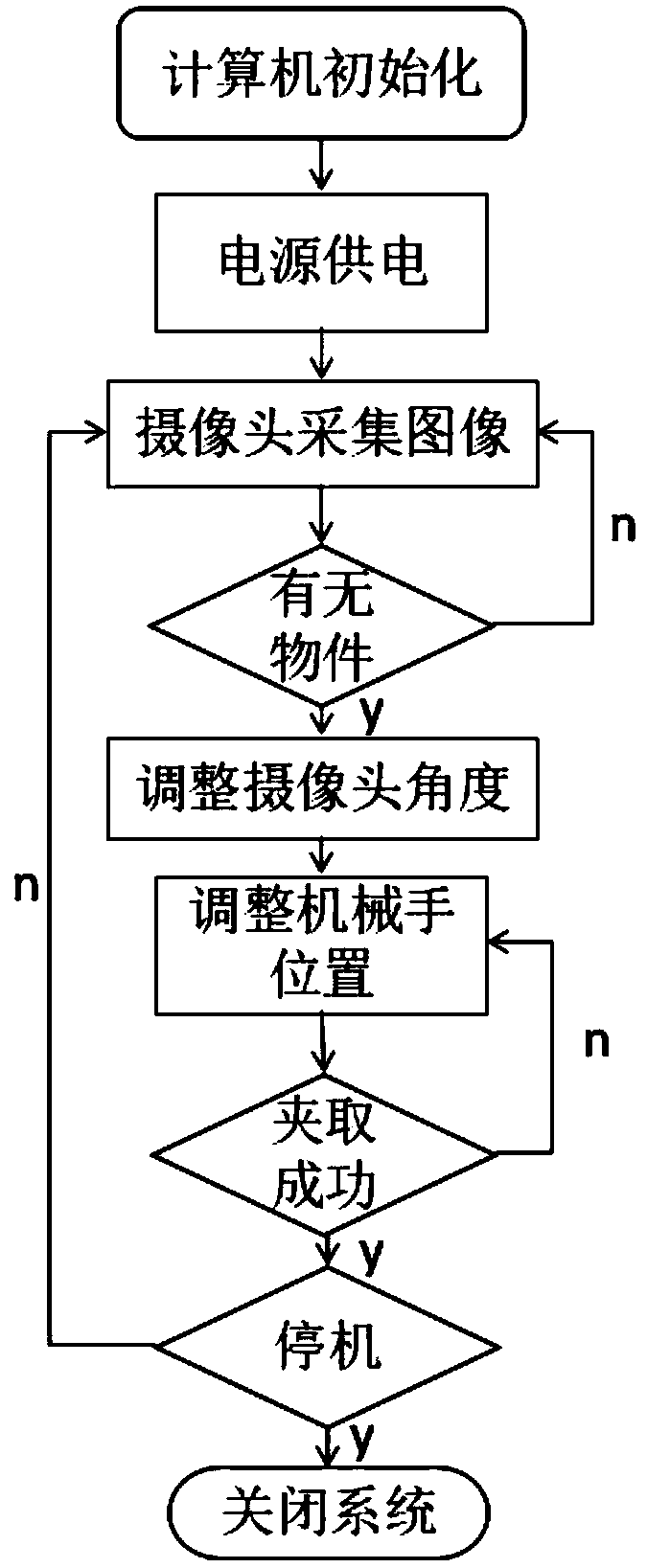

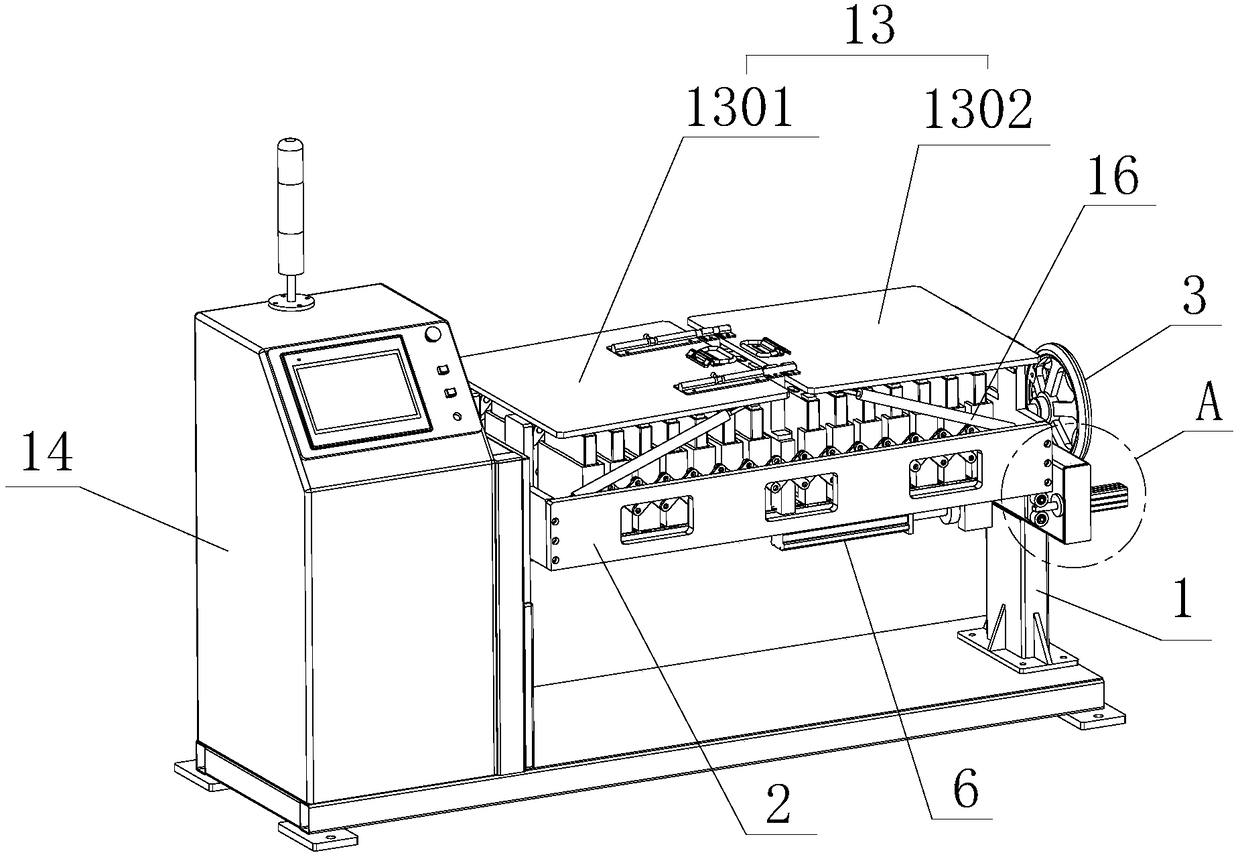

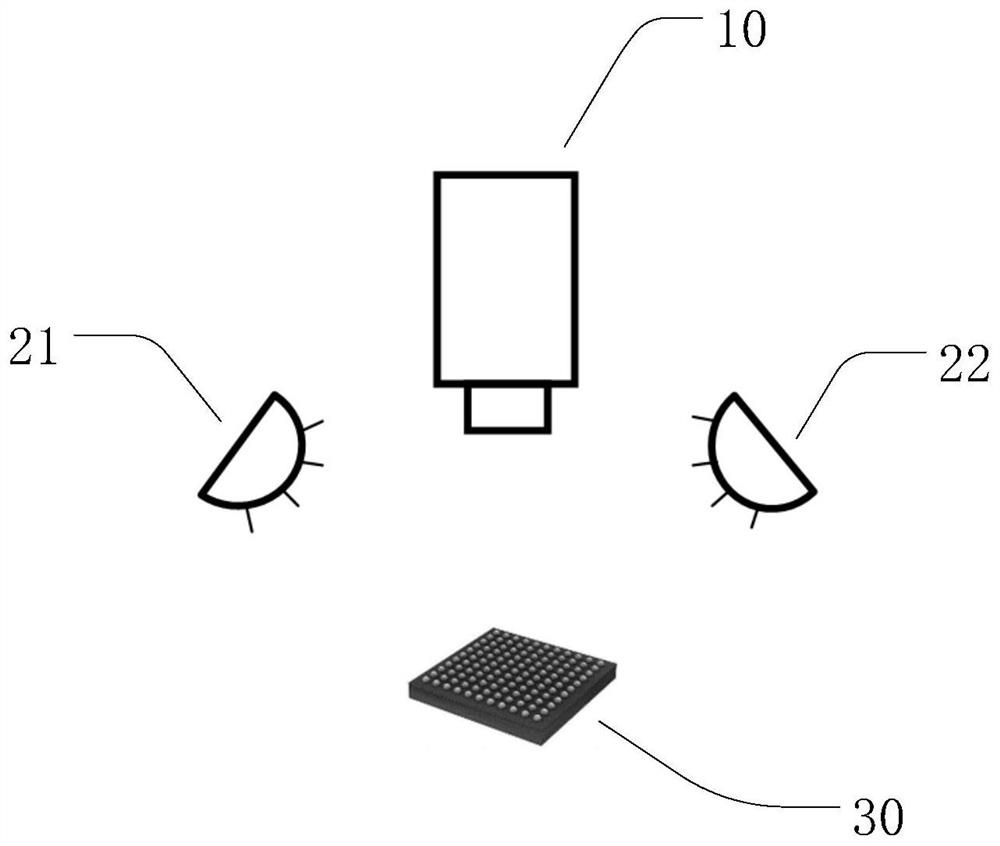

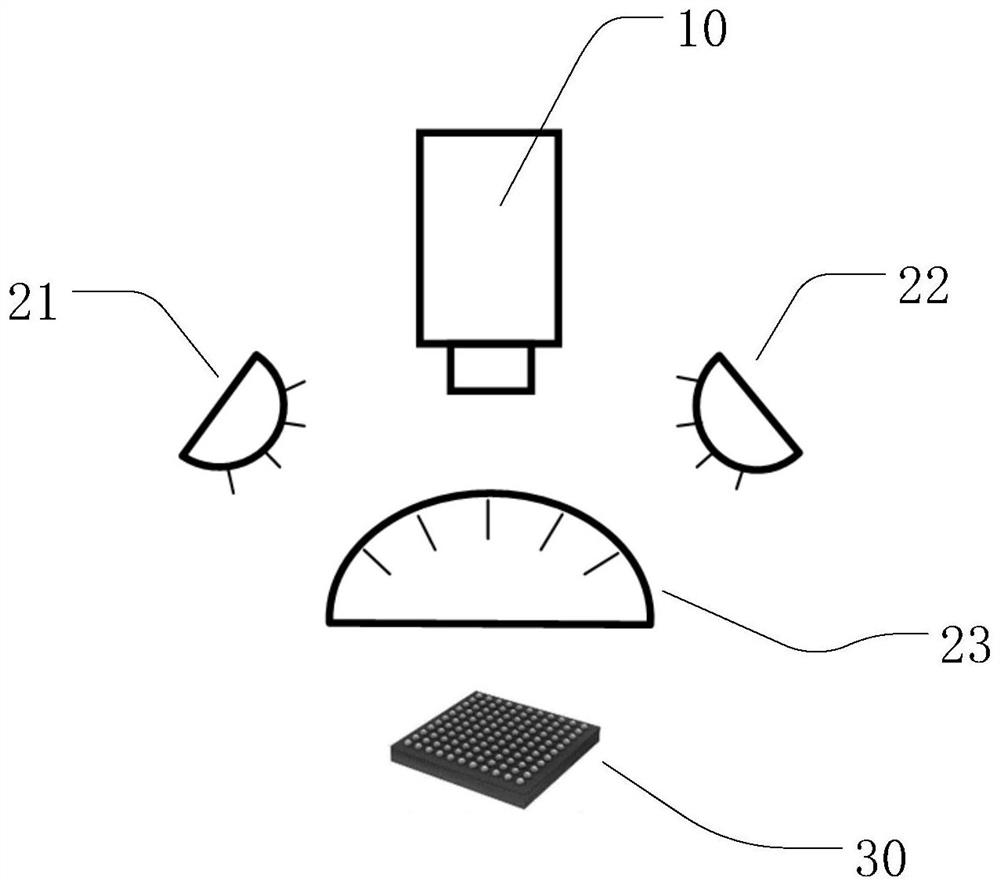

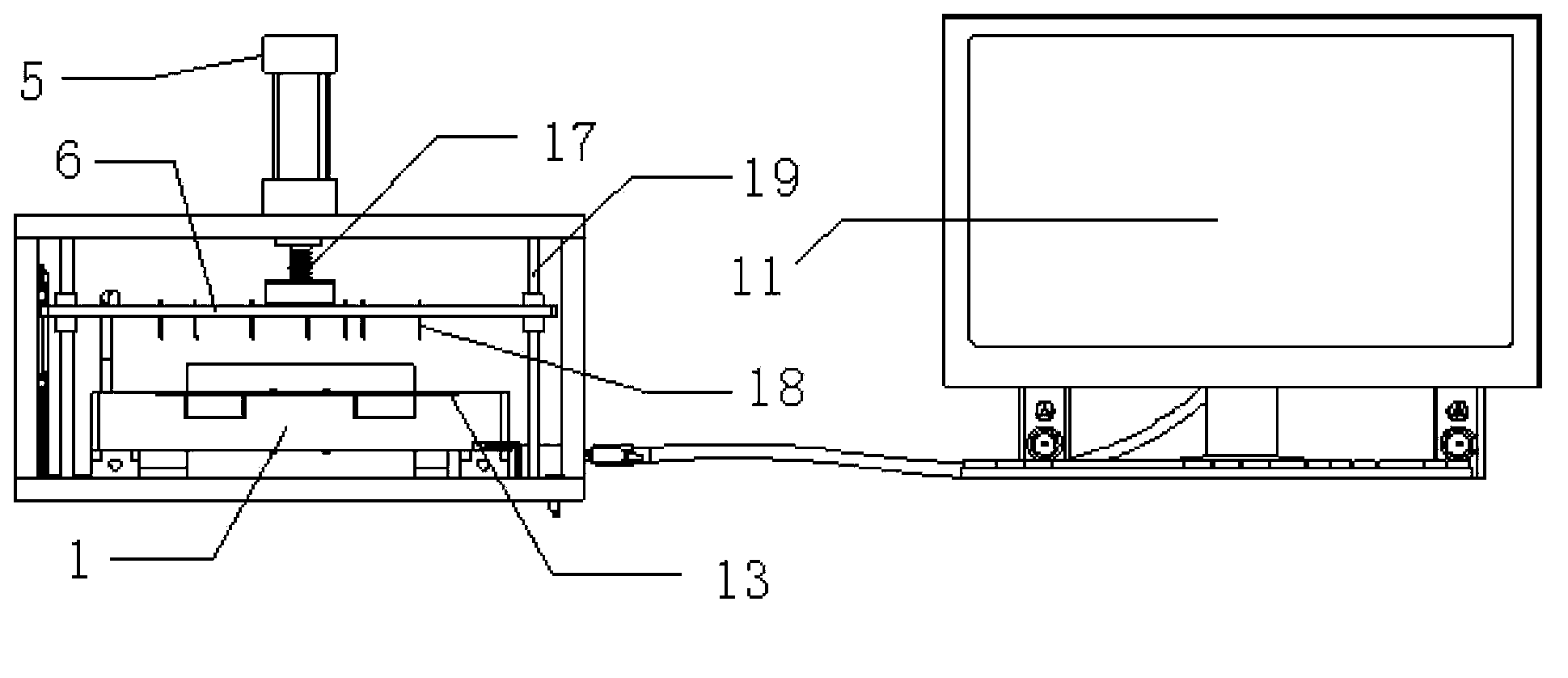

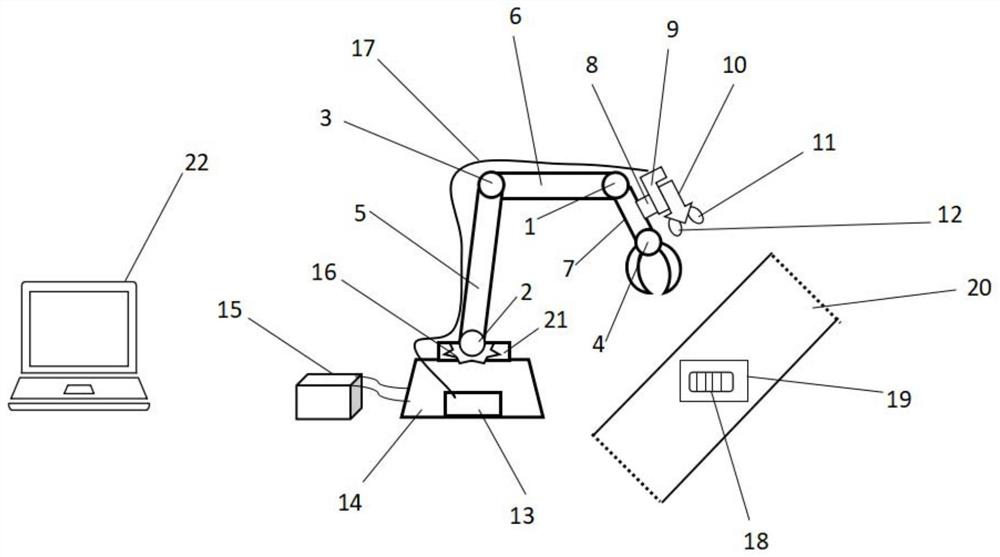

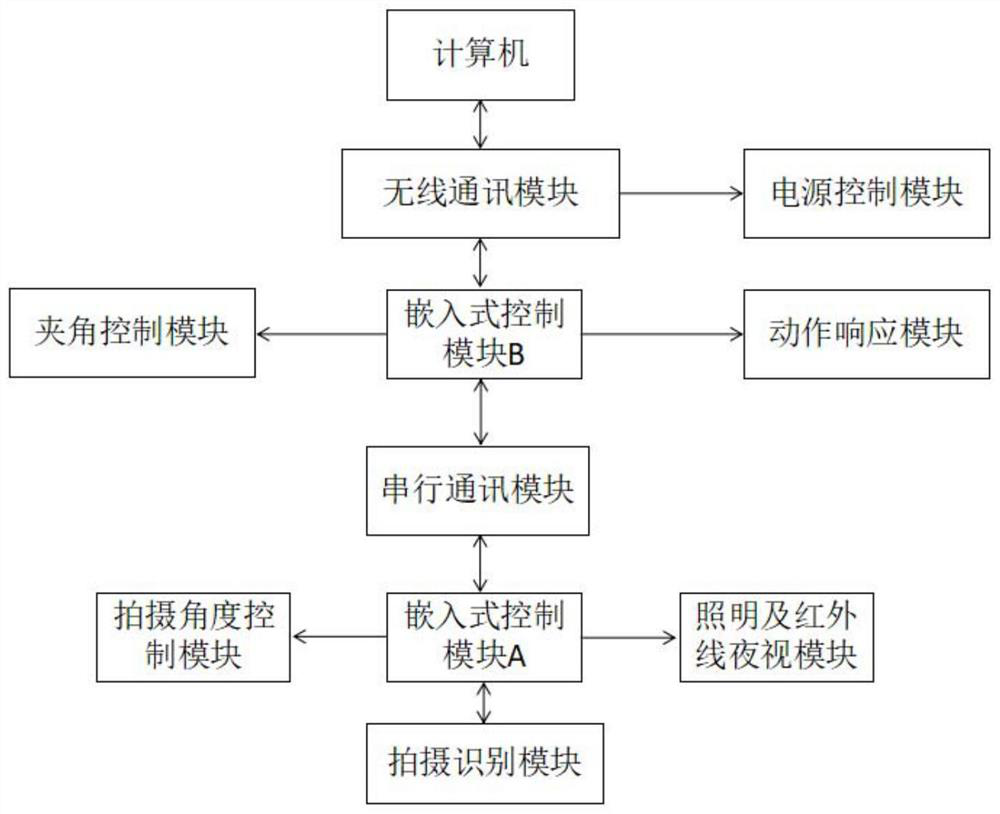

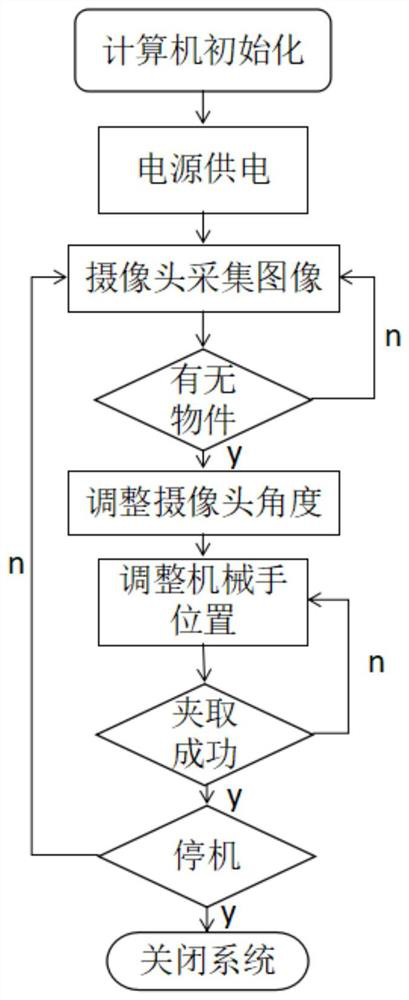

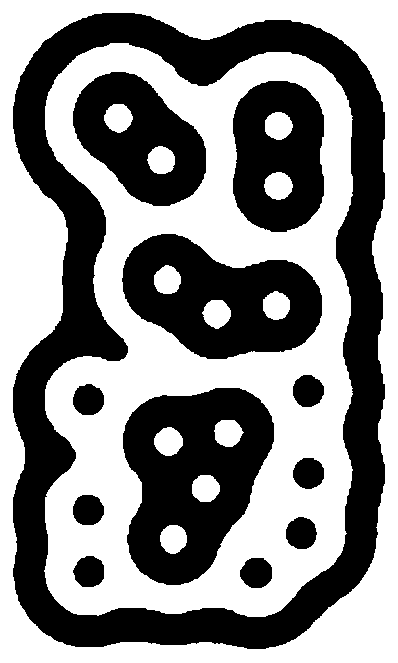

Manipulator logistics sorting system based on machine vision processing and working method thereof

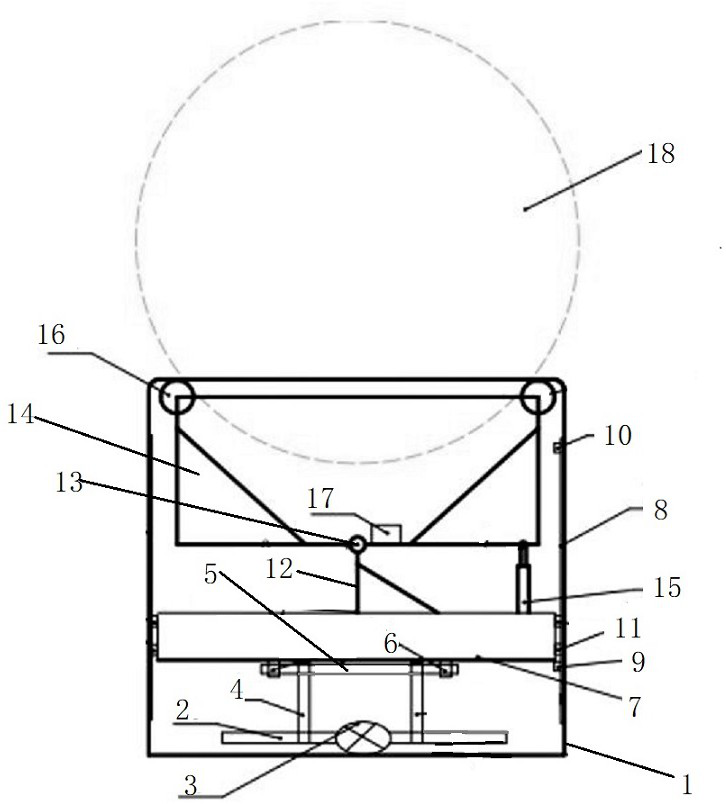

ActiveCN109433627AAccurate identificationConvenient manual inspectionSortingMachine visionLogistics management

The invention discloses a manipulator logistics sorting system based on machine vision processing and a working method thereof. The manipulator logistics sorting system includes a computer, a camera device and a manipulator, the computer communicates with the manipulator through a wireless communication network, the camera device is arranged on a telescopic clamping claw of the manipulator, and the manipulator is installed on the base. According to the manipulator logistics sorting system based on machine vision processing and the working method thereof, since the openMV camera device is usedfor machine vision processing, bar codes on logistics express delivery can be identified and contained contents are obtained, the required express delivery can be very accurately identified and sortedout, obtained information can be transmitted to the computer for storage, and manual inspecting and recording are convenient; and since the openMV camera device is adopted, the sizes of objects and the current distance from the manipulator can be judged autonomously through captured pictures, the included angle of extension required by the clamping claw of the manipulator is autonomously calculated, the problem that traditional manipulators can only operate products with the same specification in flow is solved, and applicability is high.

Owner:DALIAN MARITIME UNIVERSITY

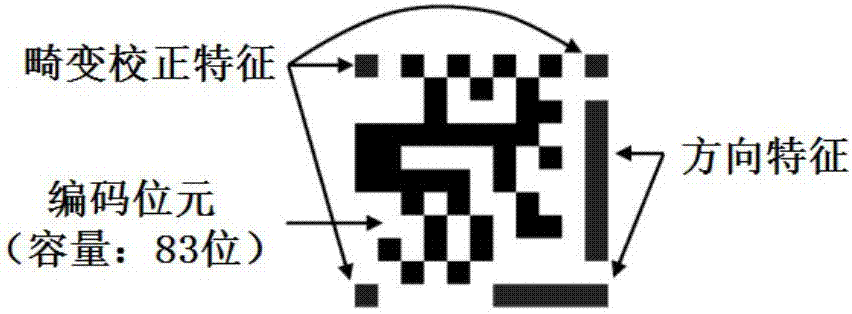

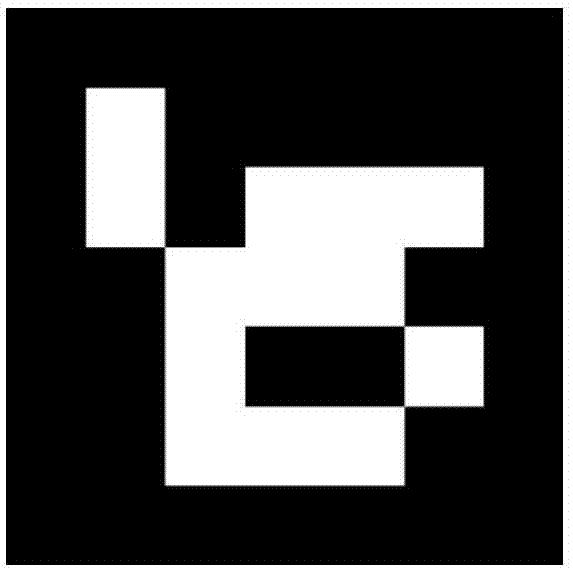

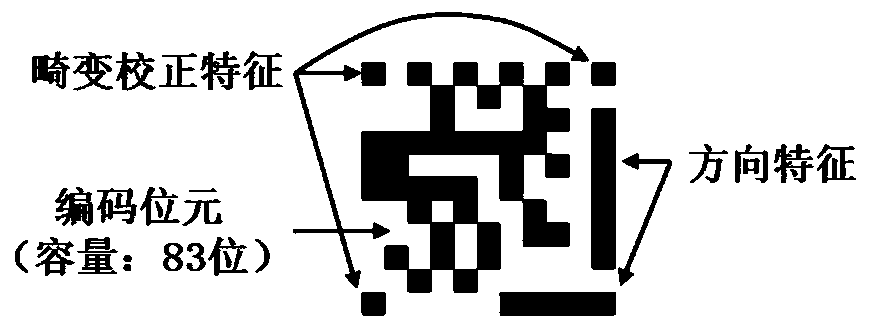

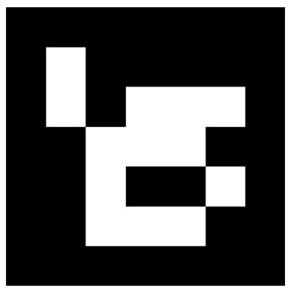

Non-mirror-symmetry two-dimensional code marking figure verification and layout method for monocular vision location

ActiveCN107578078AHas non-mirror symmetryIncrease the number of digitsImage analysisRecord carriers used with machinesGraphicsMirror reflection

The invention relates to a non-mirror-symmetry two-dimensional code marking figure verification and layout method for monocular vision location. The problems that in the prior art, when there are toomany data bits and a camera is low in precision, recognition can not be conducted, data inspection and verification can not be manually conducted, and dislocation caused by wrong two-dimensional codesare formed under the mirror condition are solved. Compared with two-dimensional code marking figures obtained through other methods, the method is simple in layout and easy to implement, data codes and verification codes are separated, and manual inspection and verification are convenient; meanwhile, the number of bits of data codes is increased, and the total number of available codes in the system is greatly increased. Two-dimensional code marking figures produced through the method have non-mirror-symmetry and are suitable for the environment with large-area mirror reflection conditions. The method is used for the field of monocular camera vision location.

Owner:HARBIN INST OF TECH

Apparent defect detection method for touch screen protective glass

InactiveCN104297259AImprove detection efficiencyImprove detection qualityOptically investigating flaws/contaminationProduction lineProtective glasses

The invention discloses an apparent defect detection method, which can rapidly detect the apparent defect of touch screen protective glass and is suitable for batch flow detection application on production lines, for the touch screen protective glass. The detection method replaces original manual detection mode, is high in detection speed, uniform in detection standards, low in omission ratio, lower in the labor intensity of operating personnel, and higher in the overall detection efficiency and quality of touch screen protective glass, adopts automatic optical visual detection, and can effectively solve problems of manual detection.

Owner:SUZHOU PTC OPTICAL INSTR

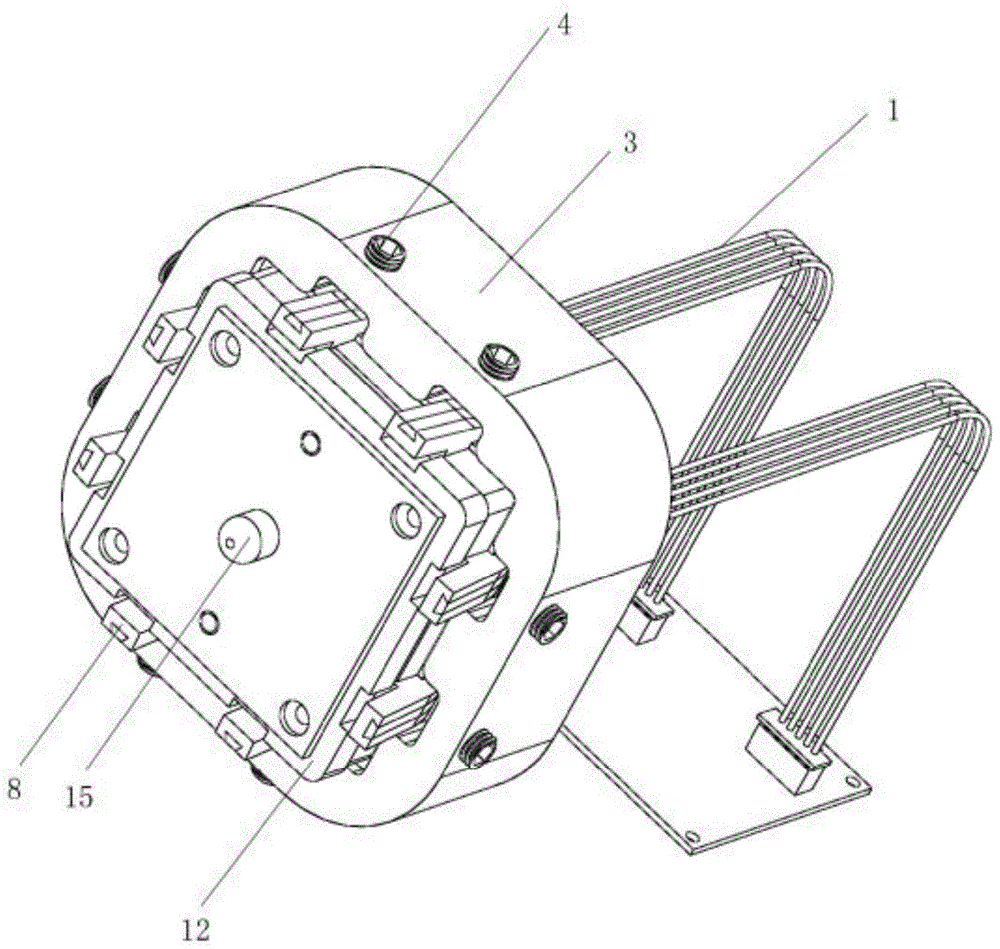

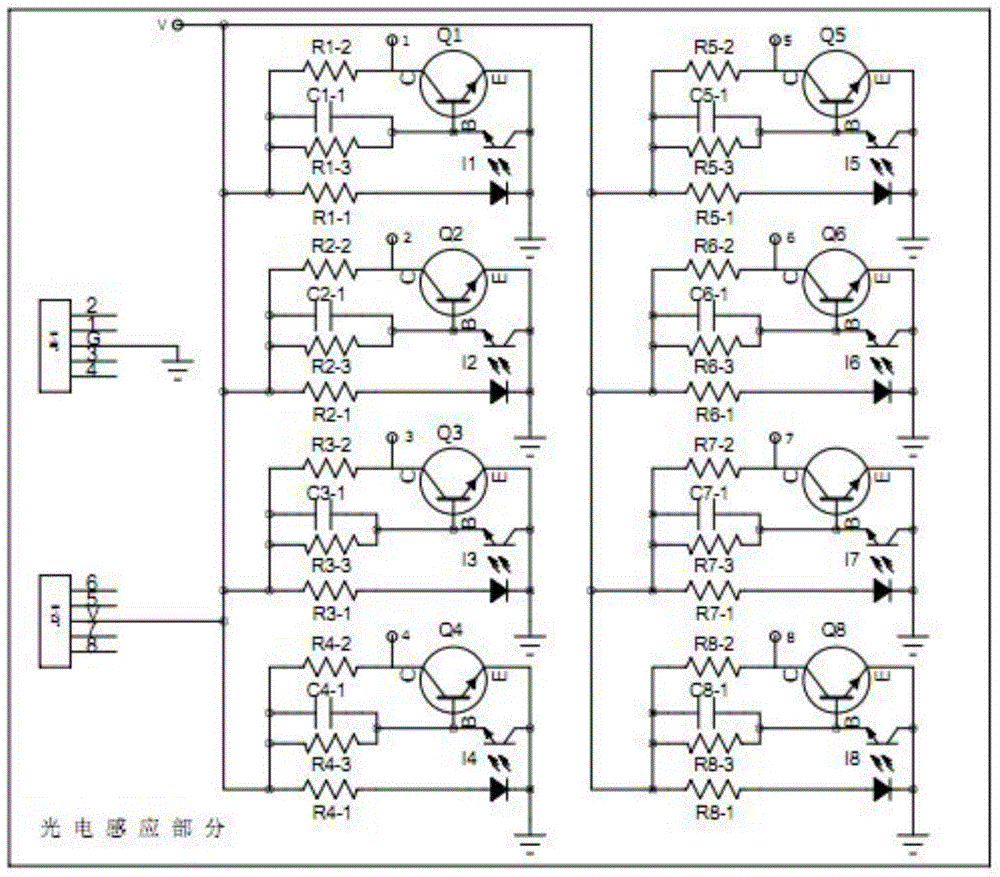

Magnet detecting device of magnet automatic assembling machine

ActiveCN104551594AConvenient manual inspectionTimely exclusionMetal working apparatusElectric/magnetic detectionMagnetic polesEngineering

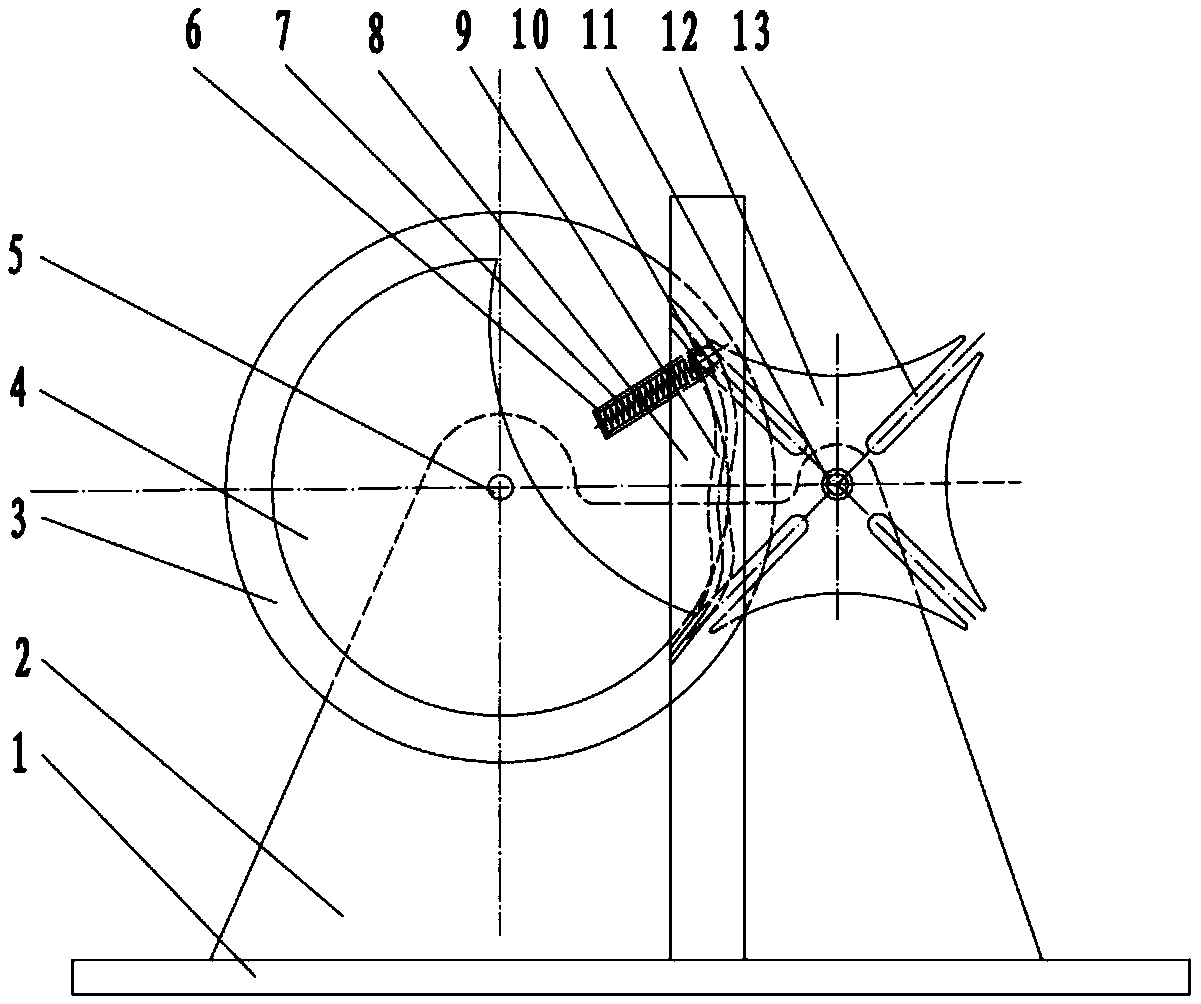

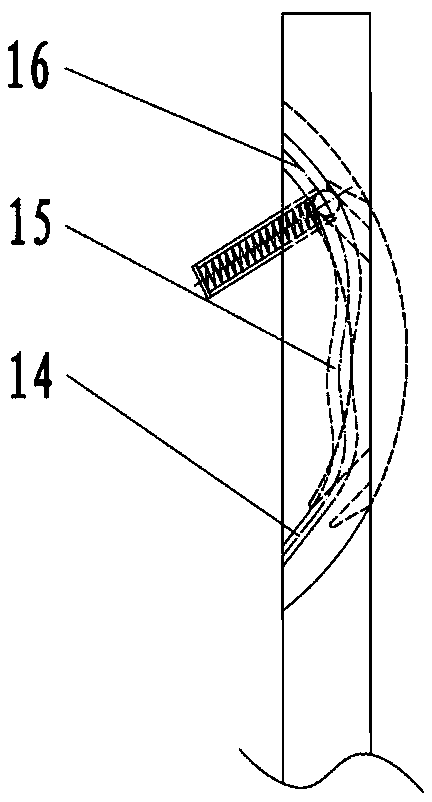

The invention relates to a magnet detecting device of a magnet automatic assembling machine. A gripper limit block, a gripper fixing seat, grippers, gripper hinge pins and a magnet limit block are arranged on the magnet detecting device, and the magnet detecting device is arranged at a position, between the gripper fixing block and the magnet limit block, on an assembling manipulator. The magnet detecting device comprises connecting wires, a sensing and detecting PCB( printed circuit board), a signal converting PCB, anti-dust sealing rings, a limit guide plate, strong magnets and magnet covers, wherein a plurality of guide holes are formed in the edge side of each of magnet grooves of the magnet limit block, the magnet covers are arranged in the guide holes, columnar magnets which can slide up and down are placed in the magnet covers, the limit guide plate for limiting the sensing and detecting PCB is arranged at the upper parts of the magnet covers, the anti-dust sealing rings are arranged between the upper ends of the guide holes and the limit guide plate, and a detector is arranged at a position, corresponding to the upper ends of the magnet covers, on the sensing and detecting PCB. Through a photoelectric tube, the condition whether the magnets are positioned under the gripper or not, and whether magnetic poles of the magnets are exactly mounted or not, can be detected, so that the yield can be greatly increased.

Owner:东莞龙昌数码科技有限公司 +1

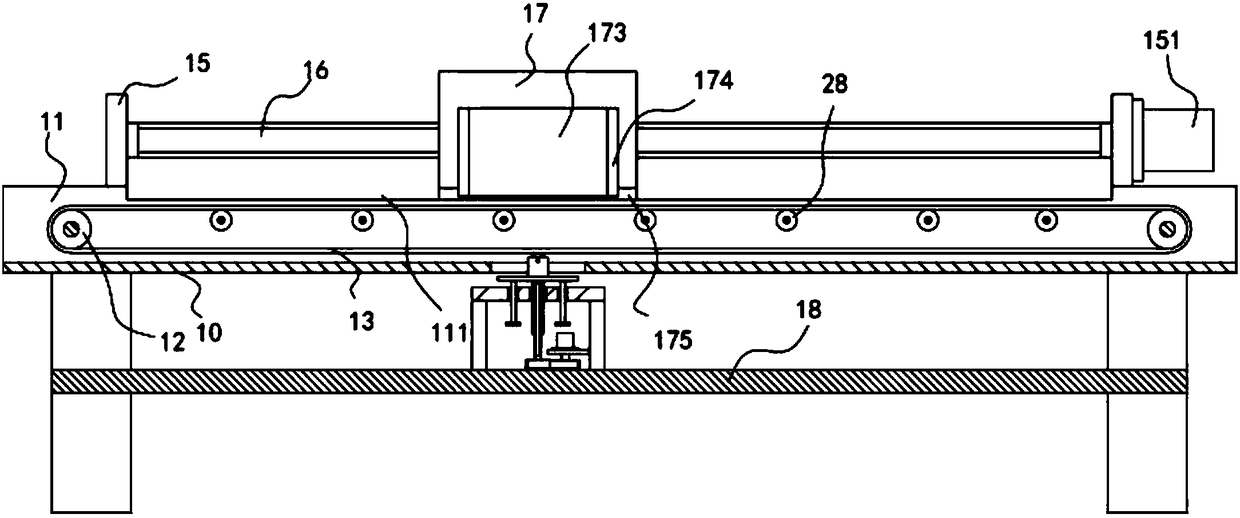

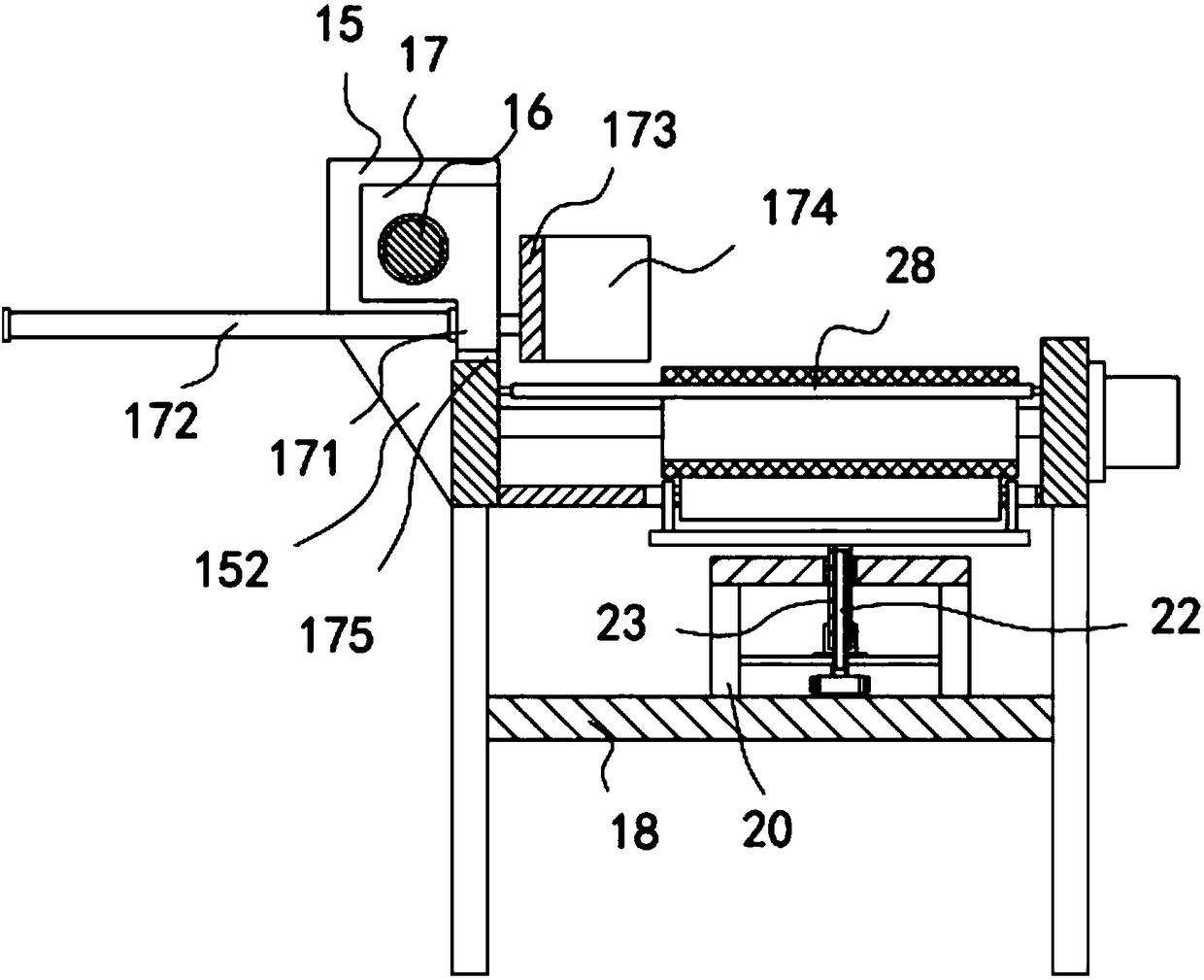

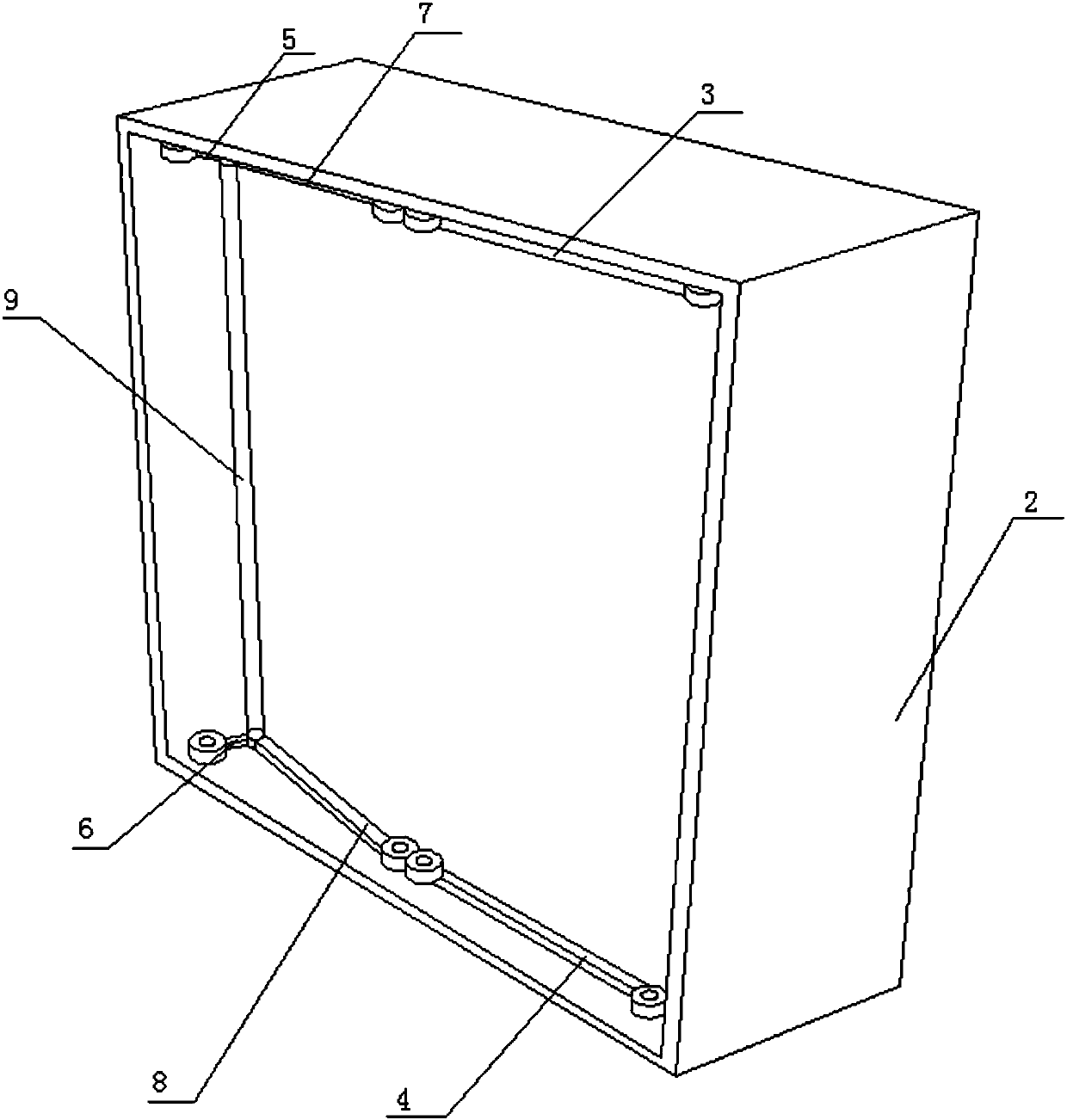

Part conveying and selecting mechanism with tensioning device

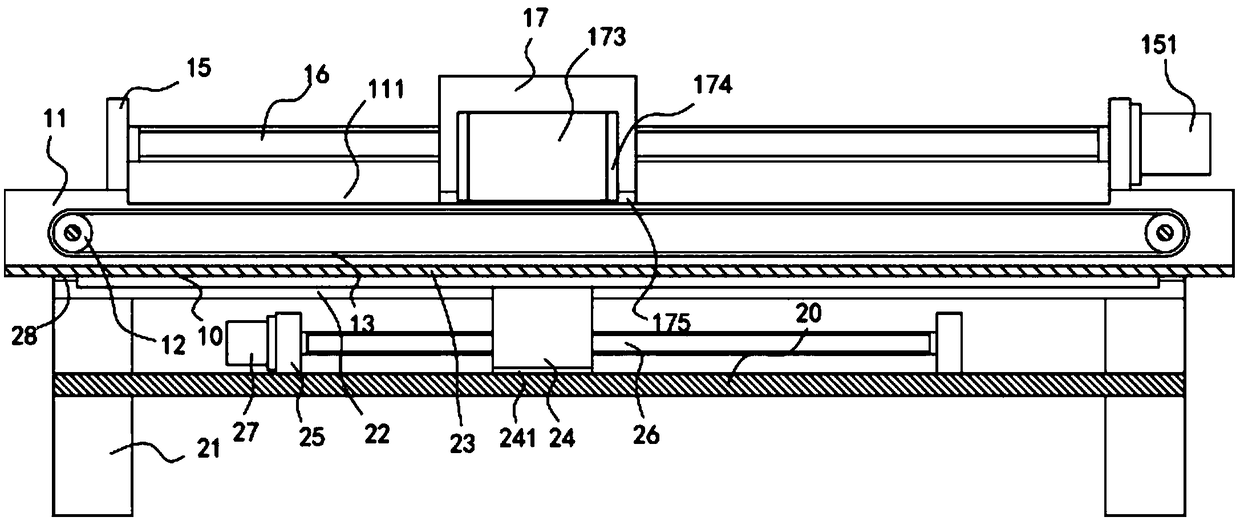

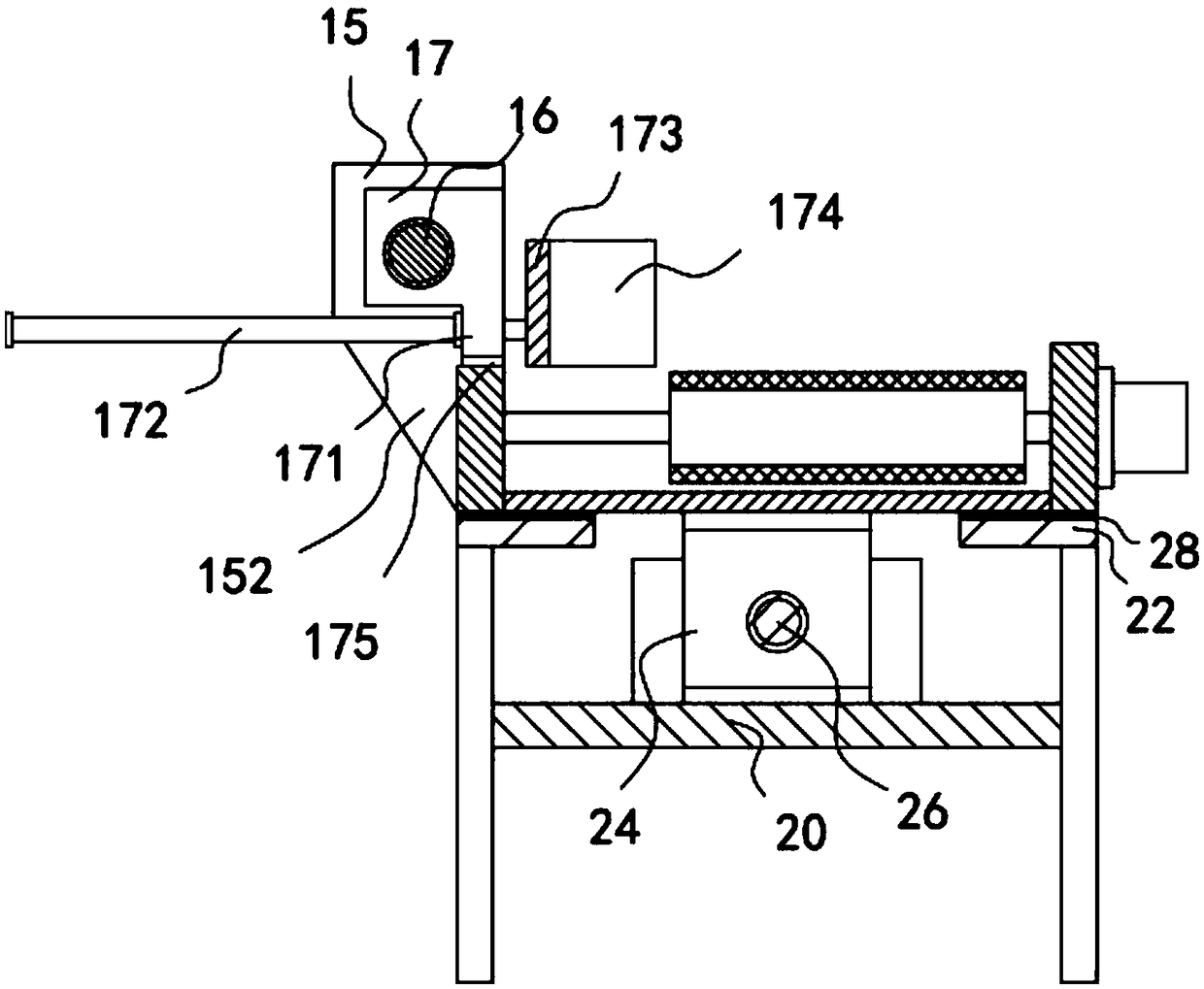

InactiveCN108438759AGood effectConvenient manual inspectionConveyorsConveyor partsMachine partsEngineering

The invention discloses a part conveying and selecting mechanism with a tensioning device. The part conveying and selecting mechanism comprises a machine frame, baffles are fixed to the front portionand the rear portion of the top surface of a top plate of the machine frame, two transmission roller bodies are located on the left side and the right side of the top plate of the machine frame correspondingly, the two ends of each transmission roller body are hinged to the corresponding two baffles, a conveying belt is tensioned on the two transmission roller bodies, and a driving motor is fixedon the outer side wall of one end of one baffle; and the inner side walls of lower supporting legs of the machine frame are fixed on a lower supporting transverse plate, and an adjusting through groove is formed in the middle of the top plate of the machine frame. The part conveying and selecting mechanism can be connected with other conveying mechanisms, so that machined parts to be detected aredirectly placed on the conveying belt through other conveying parts, and can be pushed and fall from the conveying belt to a material receiving position through operation of material pushing air cylinders when moved to a certain position, therefore, the manual detection is facilitated, for the part conveying and selecting mechanism, a product frame does not need to be carried, so that the labor amount of workers is greatly reduced, and the effect is good.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

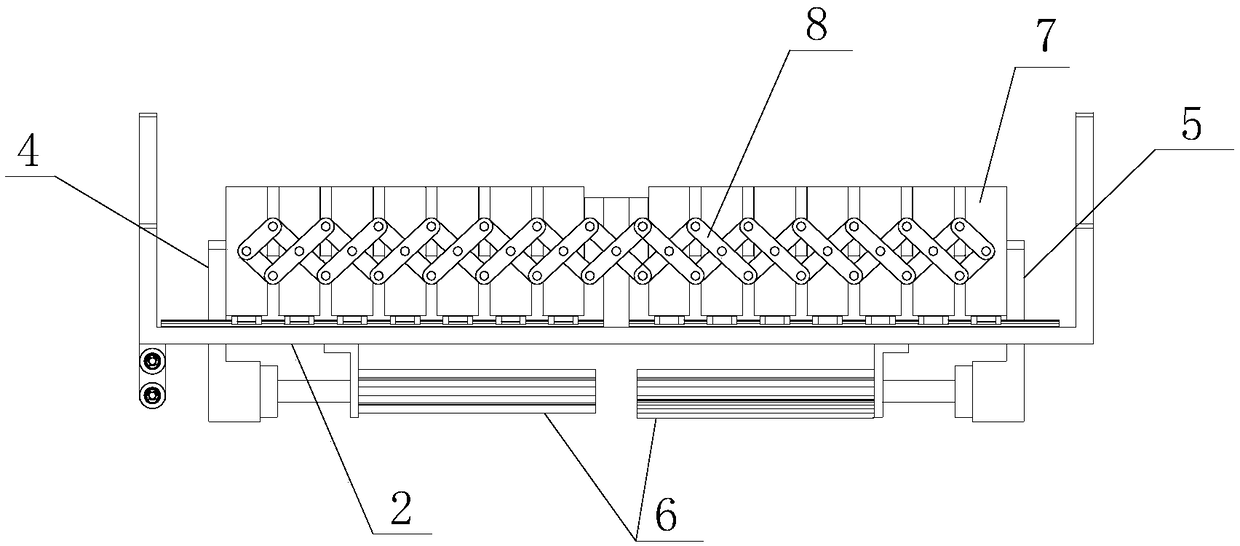

Device for detection of lithium battery electrolyte leakage

ActiveCN108871683AConvenient manual inspectionEasy to operateDetection of fluid at leakage pointElectrolyte leakageElectrolyte

The present invention discloses a device for detection of lithium battery electrolyte leakage. The device comprises a support, a holder installed on the support and a power mechanism configured to drive overturn of the holder. The holder is provided with a first pressing plate, a second pressing plate and a drive mechanism configured to drive the first pressing plate and the second pressing plateto move in an opposite direction; a plurality of installation seats are arranged between the first pressing plate and the second pressing plate on the holder, the installation seats are arranged to form at least one installation seat row, connection rod mechanisms are arranged to allow the installation seats in each installation seat row to be mutually connected, and the two ends of the connectionrod mechanisms are connected with the first pressing plate and the second pressing plate and pull the installation seats to be close to each other or far away from each other with the motion of the first pressing plate and the second pressing plate. The device for detection of lithium battery electrolyte leakage amplifies the place of the electrolyte leakage to allow workers to conveniently detect the battery leak electrolyte. The device is safe and reliable, simple to operate and high in detection efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

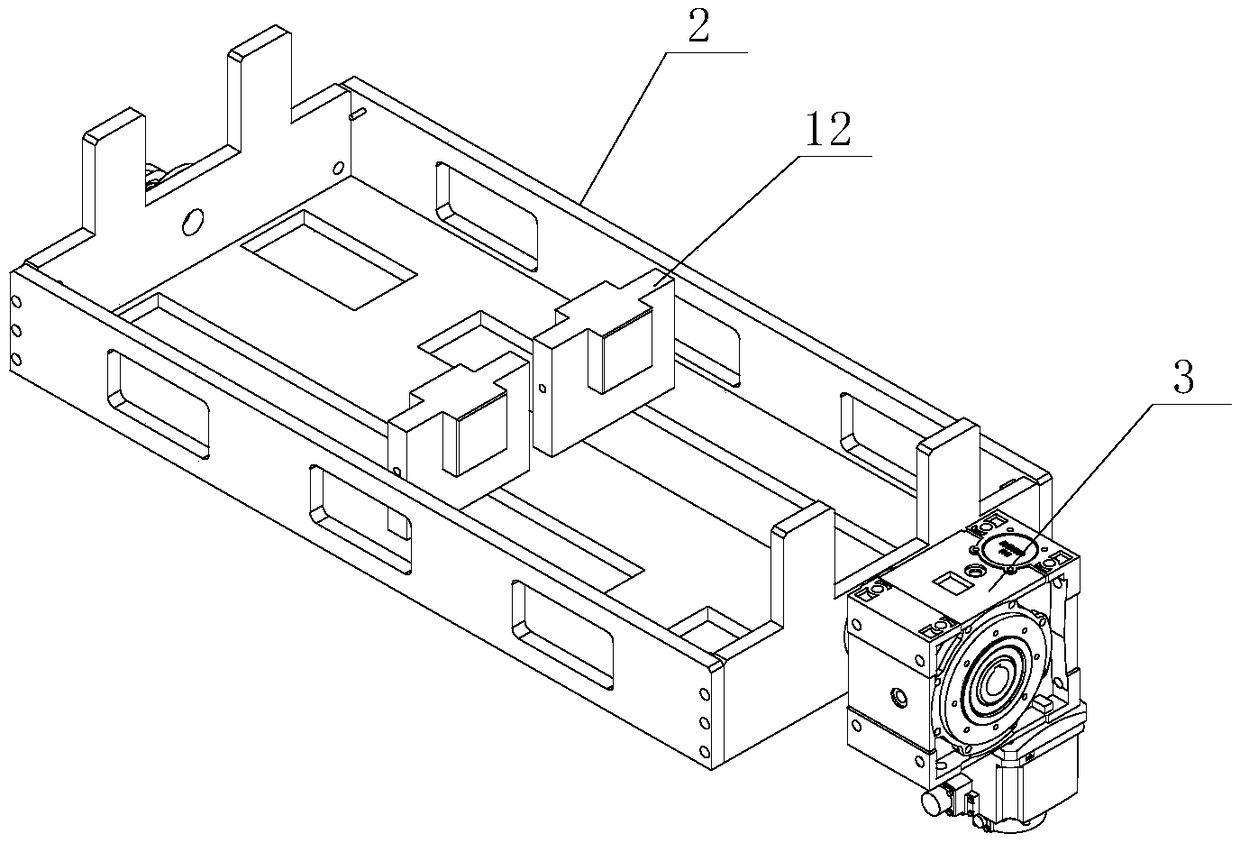

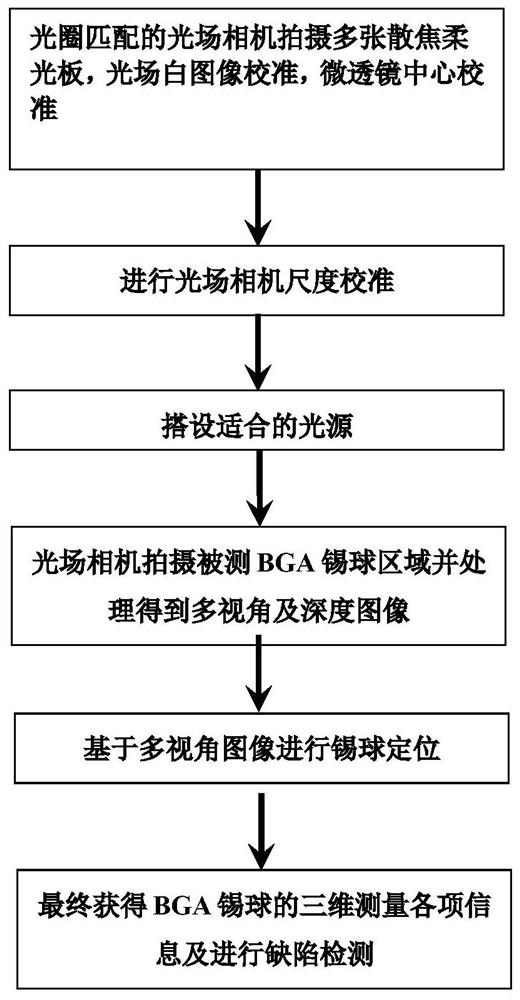

BGA packaging solder ball detection system and method

InactiveCN112747670AAccurate and stable detection abilityAvoid Welding InstabilityOptically investigating flaws/contaminationUsing optical meansSolder ballEngineering

A BGA packaging solder ball detection system comprises a light field camera and a light source, wherein a lens faces a to-be-detected BGA packaging solder ball, and the light field camera is used for acquiring an image of the solder ball; and the light source emits light to the BGA packaging solder ball and is used for helping the light field camera to obtain an image of the solder ball. The detection process of the solder ball comprises the following steps of: adjusting the focal length and / or aperture of the light field camera, acquiring a plurality of defocused soft light pure color calibration plates of the BGA packaging solder ball, and acquiring a light field white image of the solder ball; calibrating the light field white image, and calibrating the center of a micro lens of the light field camera; performing scale calibration on the light field camera; erecting and adjusting the light source; shooting a to-be-detected BGA solder ball region array through using the light field camera to obtain a multi-view image and a depth image; according to the light field multi-view image and the depth image, carrying out position identification and positioning of the solder ball; and finally, acquiring three-dimensional size measurement information and defect detection information of the detected solder ball.

Owner:VOMMA (SHANGHAI) TECH CO LTD

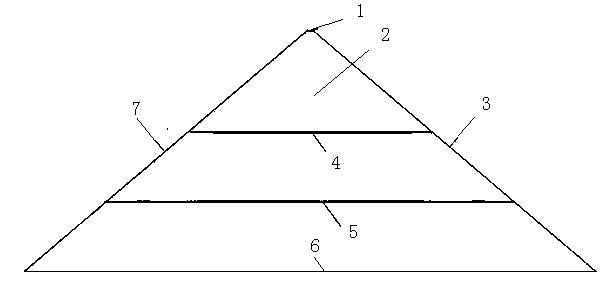

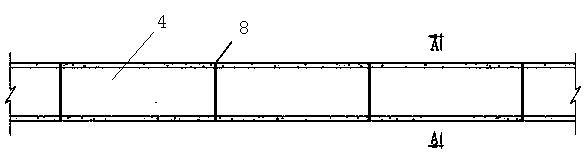

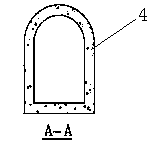

Inner deformation monitoring method and device for high earth-rock dam

InactiveCN103528560AChange design methodChange monitoring methodMeasurement devicesDeformation monitoringEngineering

The invention discloses an inner deformation monitoring method and device for a high earth-rock dam. The method is characterized in that a monitoring device is arranged on different sections and different elevations in the high earth-rock dam. The monitoring device is a prestress prefabricating gallery, and a deformation monitoring instrument is arranged in the gallery in a segmented mode; the length of each section of the prefabricating gallery is 2.0m; and flexible material is filled between sections of prefabricating gallery. According to the invention, the problems of the adaptability and the reliability of a long-distance deformation monitoring instrument are solved, and meanwhile, the problems that the cable of the monitoring instrument in the earth-rock dam is overlong and is difficult to protect are solved according to the arrangement of the monitoring gallery, thereby being more convenient for manual inspection and examination.

Owner:POWER CHINA KUNMING ENG CORP LTD

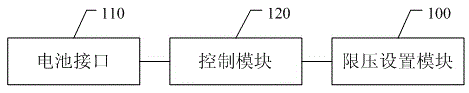

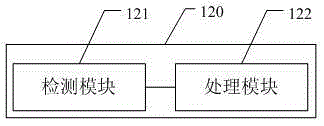

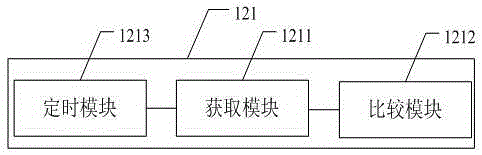

Battery factory voltage limiting method and device

ActiveCN105261802AEasy maintenanceReduce labor costsSecondary cells testingSecondary cells charging/dischargingLower limitElectrical battery

The invention discloses a battery factory voltage limiting method and device. The device comprises a voltage limit setting module, a battery interface and a control module, wherein the voltage limit setting module is used for setting a matched battery factory voltage limiting range in advance according to the characteristics of different batteries; the factory voltage limiting range comprises an upper limit voltage and a lower limit voltage; the battery interface is used for connecting an anode and a cathode of the battery and the device; and the control module is used for starting the device, carrying out discharging or charging on the battery which is connected with the device and closing the device when detecting that the battery voltage is within the factory voltage limit range. The factory battery is connected with the device disclosed by the invention, so that the factory battery voltage is controlled within the matched factory voltage limiting range by the device; the safety of the battery in a transportation process is facilitated; maintenance of the battery voltage is also facilitated; the labor cost for inspecting the battery voltage before leaving the factory can be reduced; and the inspection accuracy is also ensured.

Owner:东营慧达科技创业服务有限公司

Office energy-saving control system and method

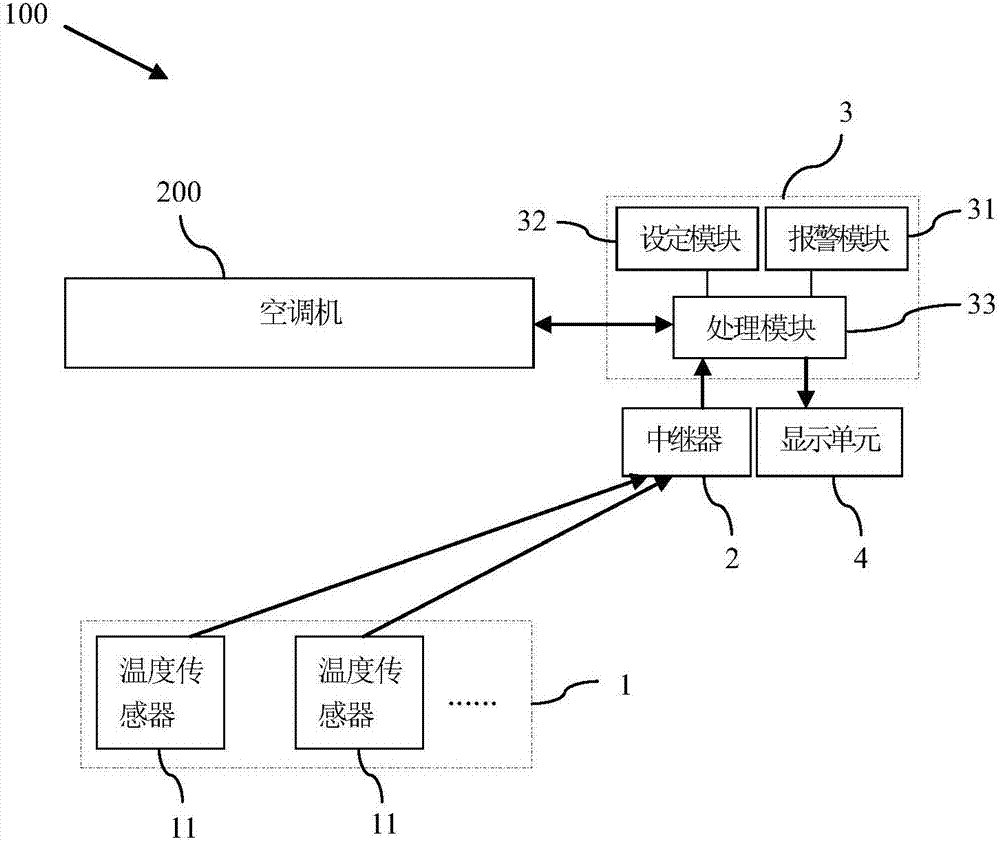

InactiveCN107421057AConvenient manual inspectionConvenient manual inspection and adjustmentSpace heating and ventilation safety systemsLighting and heating apparatusWork periodControl system

The invention provides an office energy-saving control system and method. Owing to the fact that the environment temperatures of different areas of an office are collected by temperature sensing units, a temperature heap map is drawn through a processing unit, the temperatures of all the office areas are intuitively shown, the situation that the office structure is manually detected and adjusted is facilitated, indoor temperature adjusting is accelerated, and energy consumption of an air conditioner is reduced; the air conditioner is automatically turned on and off through the processing unit according to the set working date, on-duty and off-duty time and overtime of the office energy-saving control system, and therefore the unnecessary working time of the air conditioner is reduced; and thus, according to the office energy-saving control system, energy waste can be effectively reduced, and the more energy-saving and comfortable office environment is created.

Owner:上海纳普信息科技有限公司

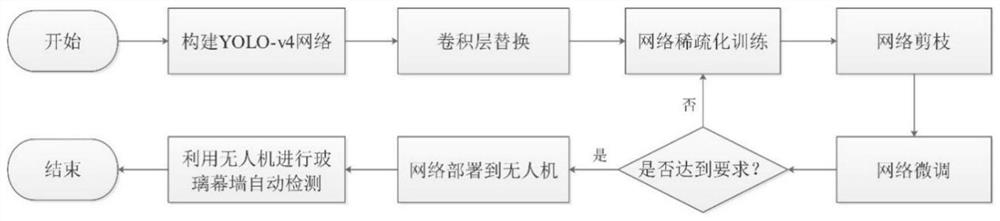

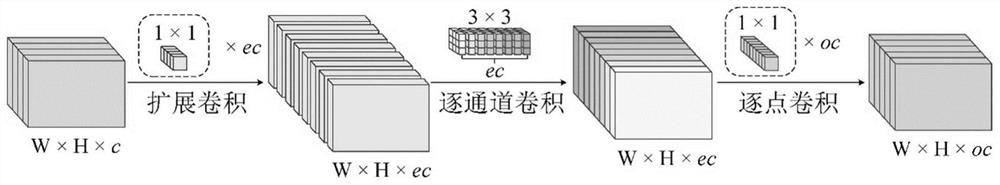

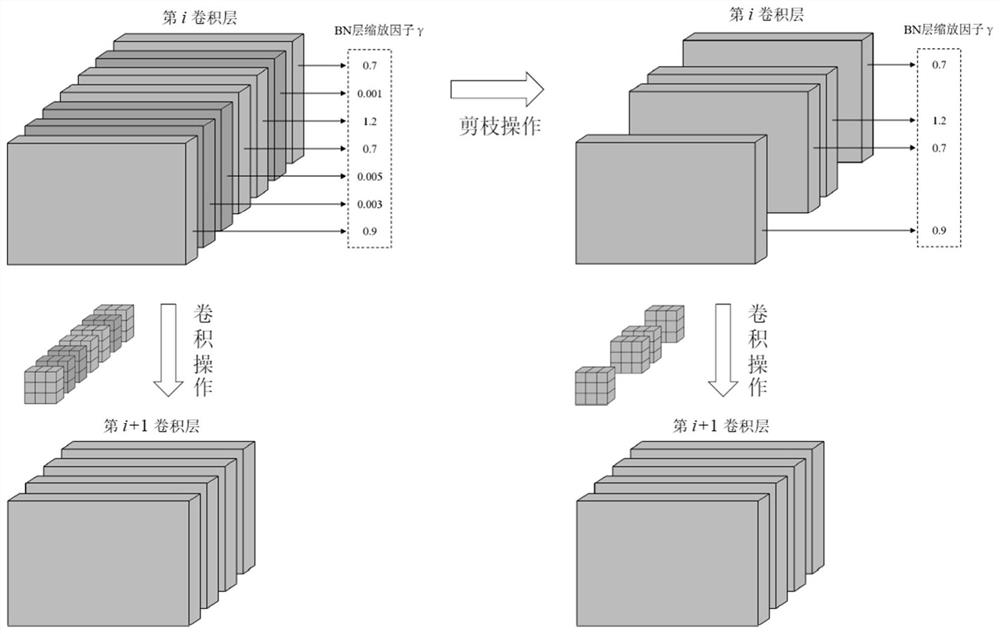

Automatic detection method for damage of glass curtain wall of high-rise building

ActiveCN114120154AReduce the amount of parametersChange manual inspectionCharacter and pattern recognitionNeural architecturesArchitectural glassAlgorithm

The invention relates to an automatic detection method for damage of a glass curtain wall of a high-rise building, and the method comprises the steps: constructing a detection network, carrying out the training and verification of the constructed detection network through a sample set, and obtaining a detection network with optimal parameters. A convolutional layer in the YOLO v4 network is replaced by expansion convolution, channel-by-channel convolution and point-by-point convolution which are connected in sequence to obtain a new convolutional layer, and finally, the YOLO v4 network after replacement is used as a constructed detection network; pruning the detection network with the optimal parameters according to the scaling factor vectors of all the BN layers; and finally, performing fine tuning on the pruned detection network with the optimal parameters by using the sample set to obtain a final detection network. Therefore, the method further reduces the parameter quantity of the model on the premise of ensuring high accuracy, and realizes the full-automatic detection of the glass curtain wall of the urban high-rise building based on the unmanned aerial vehicle.

Owner:NINGBO UNIV

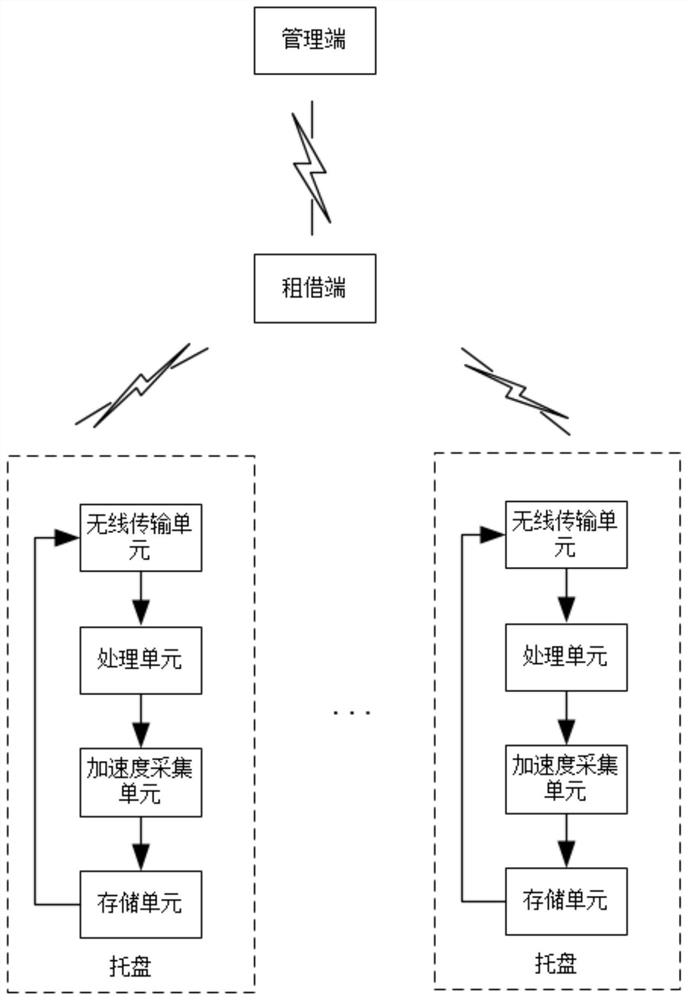

Tray management platform

InactiveCN112734513AAutomate managementConvenient manual inspectionApparatus for meter-controlled dispensingBuying/selling/leasing transactionsPaymentOperating system

The invention relates to the technical field of tray leasing, and particularly discloses a tray management platform which comprises a tray storage device and a leasing end. A plurality of rentable trays are stored in the tray storage device; the renting end is also used for selecting a rented tray from the rentable trays after receiving the payment information; sending a renting instruction to the tray storage device; the renting end is also used for sending an activation instruction to the rented tray; the rented tray is used for starting to collect acceleration data after receiving the activation instruction; the renting end is also used for sending a data return instruction to the rented tray corresponding to the user after obtaining a return request of the user; and the renting end is also used for analyzing the acceleration data, judging whether the acceleration is greater than a warning threshold value or not, If so, marking the rented tray corresponding to the condition that the acceleration is greater than the warning threshold value as an abnormal tray. By the adoption of the technical scheme, when the trays are returned, the trays which may be damaged can be recognized.

Owner:重庆斯铂电气自动化设备有限公司

Chinese-rose-flower cultivation method

InactiveCN107006329AHealthy and effective growthGood loosenessGrowth substratesCulture mediaDiseasePest control

The invention discloses a Chinese-rose-flower cultivation method, and belongs to the technical field of Chinese-rose-flower cultivation. The Chinese-rose-flower cultivation method includes the following steps of 1, Chinese-rose-flower branch pretreating; 2, cultivating soil selecting, wherein cultivating soil is prepared from, by weight, 20-30 parts of decomposed cow dung, 40-50 parts of garden soil, 10-20 parts of sandy soil, 5-10 parts of coal ash, 10-20 parts of saw dust, 5-8 parts of vegetable leaf juice and 4-7 parts of bone meal; 3, cutting; 4, watering; 5, pest and disease controlling; 6, transplanting. According to the Chinese-rose-flower cultivation method, the looseness and the air permeability of soil are good, Chinese rose flowers can fully absorb nutriments accordingly, and healthily and effectively grow; in addition, diseases and pests can also be well prevented.

Owner:明光市裕阳新材料有限公司

Height adjustable component conveying and material selecting mechanism

InactiveCN108622639AGood effectConvenient manual inspectionConveyorsConveyor partsDrive motorEngineering

The invention discloses a height adjustable component conveying and material selecting mechanism. The height adjustable component conveying and material selecting mechanism comprises a rack. Baffles are fixed to the front portion and the rear portion of the top face of a top plate of the rack, and two transmission rollers are located on the left side and the right side of the top plate of the rack, and the two ends of the transmission rollers are hinged to the two corresponding baffles. A conveying belt is tensioned on the two transmission rollers, a drive motor is fixed to the outer side wallof one end of one baffle, and an output shaft of the drive motor is a spline shaft, wherein the spline shaft is inserted in a spline hole in one end of the corresponding transmission roller in a sleeved manner. The height adjustable component conveying and material selecting mechanism can be connected with other conveying mechanisms, the height of the conveying belt can be adjusted, it is guaranteed that the conveying belt and adjacent conveying equipment are matched in height, machined to-be-detected components are directly placed on the conveying belt through other conveying components, themachined to-be-detected components move to a certain position, through running of a pushing air cylinder, the to-be-detected components can be pushed to fall to the material receiving position from the conveying belt, manual detection is convenient, and product frames do not need to be carried.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

Method for cultivating rosa chinensis

The invention discloses a method for cultivating rosa chinensis and belongs to the technical field of rosa chinensis cultivation. The method comprises the following steps: 1. rosa chinensis branch pretreatment; 2. cultivation soil selection: cultivation soil is prepared from the following raw materials in parts by weight: 20-30 parts of decomposed cattle manure, 40-50 parts of garden soil, 10-20 parts of sandy soil, 5-10 parts of coal ash, 10-20 parts of sawdust, 5-8 parts of vegetable leaf juice and 4-7 parts of bone meal; 3. cutting; 4. watering; 5. disease and insect pest control; and 6. transplanting. According to the method, the adopted soil is relatively good in looseness and air permeability, so that the rosa chinensis can adequately absorb nutrients, and thus, the rosa chinensis can healthily and effectively grow; and furthermore, plant diseases and insect pests can be better controlled.

Owner:HEFEI XUELIXIN AGRI TECH CO LTD

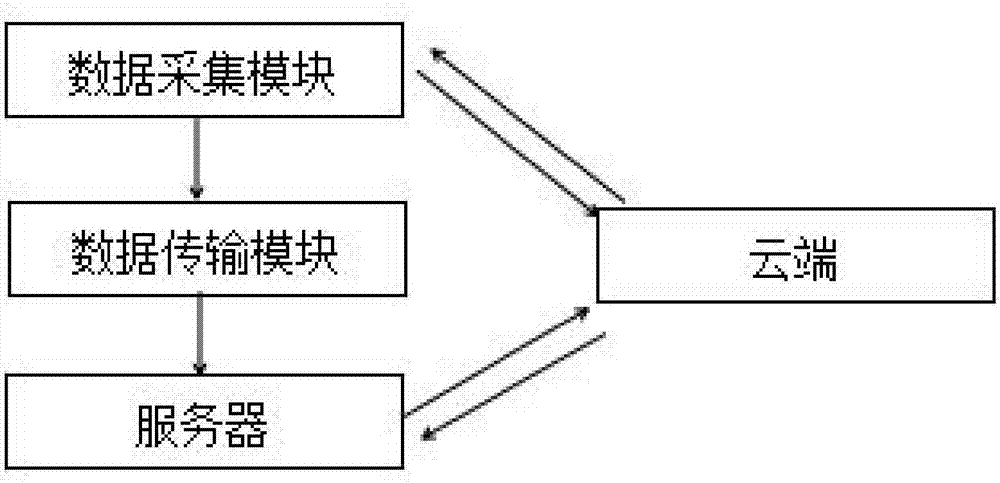

Stone internet-of-things handset system and management method thereof

InactiveCN107256489ASimplify the management processRealize upgradingBuying/selling/leasing transactionsManagement efficiencyClient-side

The invention discloses a stone internet-of-things handset system and a management method thereof. The system comprises a cloud end, a data collection module, a data transmission module and a server, wherein the data collection module is used for collecting related data of stones; the data transmission module transmits the collected related data to the server; the server analyzes and judges whether the related data is abnormal or not, provides a solution, and prints and outputs the related data according to the demand of a client; and the cloud end is used for storing all the related data of the stones. Tags are arranged on the stones, the data collection module obtains the related data through the tags, then the data is transmitted to the server through the data transmission module, and the data is transmitted to the cloud end for storage; and the server receives and analyzes the data, transmits a result to the client and stores the result in the cloud end. The manual statistics, manual inspection and manual printing of production management are greatly improved and the purposes of reducing the cost and improving the management efficiency are achieved.

Owner:曹孝忠

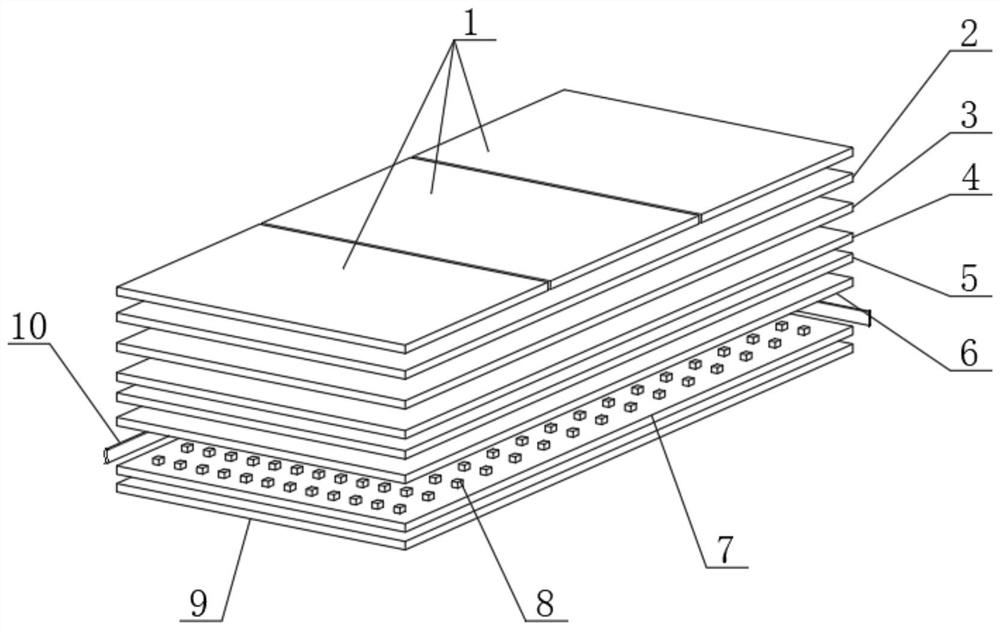

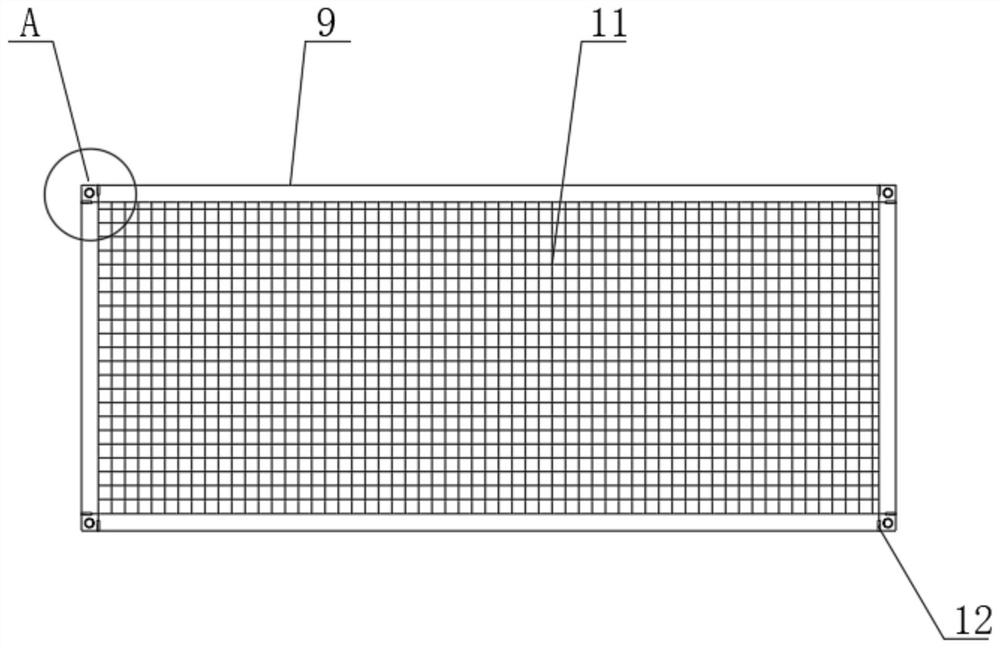

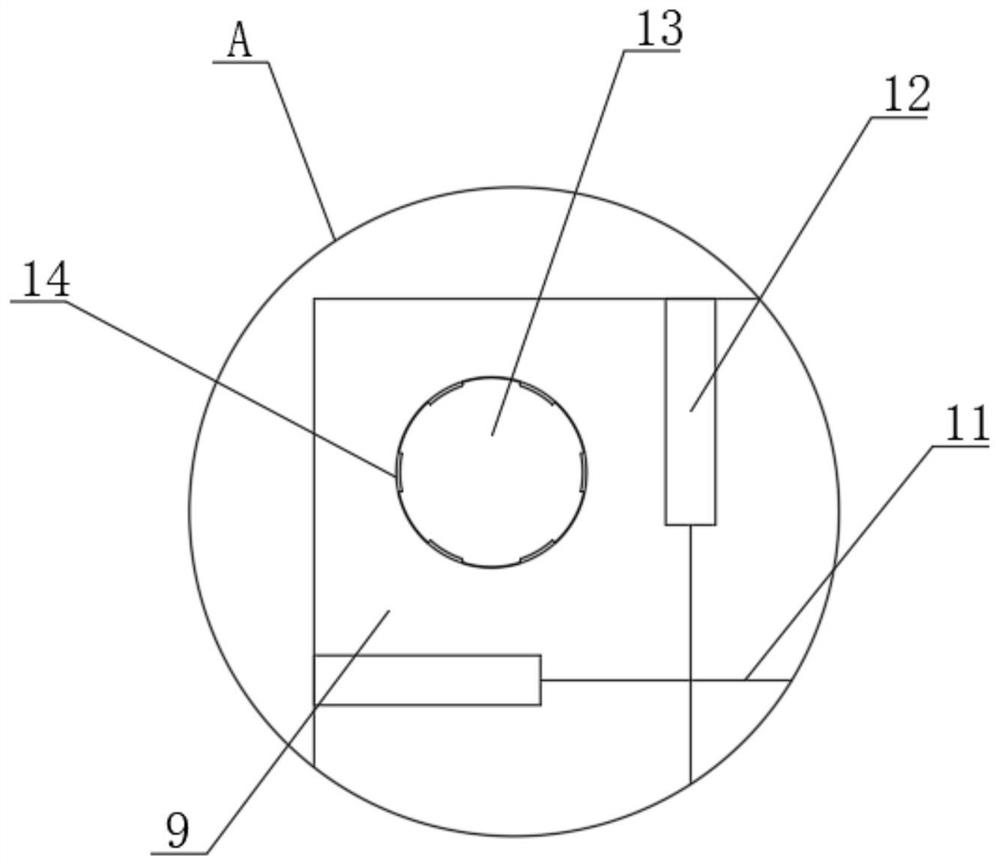

Light and thin MiniLED backlight source

PendingCN113419379AReduced precision requirementsReduce consumptionNon-linear opticsColor gelQuantum dot

The invention discloses a light and thin MiniLED backlight source which comprises a back plate and a light source assembly, an auxiliary marking line is arranged at the midpoint of the top end face of the back plate, through holes are further formed in the four corners of the back plate, an integrated inner cover plate is arranged in the through holes, a plurality of arc grooves are formed in the surface of the inner cover plate at equal angles, the cross section of each arc groove is of an arc structure, the four corners of the back plate are each provided with two edge grooves, the two edge grooves are perpendicularly distributed, and the through holes are formed in the inner sides of the two edge grooves. The light source assembly is composed of a backlight assembly, a light equalizing piece, a quantum dot color enhancement film, an optical thin film, a liquid crystal panel, liquid crystal and a color filter which are sequentially stacked from bottom to top. Through the designed auxiliary marking line, installation guidance can be provided for installation equipment, the precision requirement for the installation equipment is lowered, cost consumption is reduced to a certain degree, and meanwhile later manual detection can be facilitated.

Owner:HEYUAN COE COMM TECH

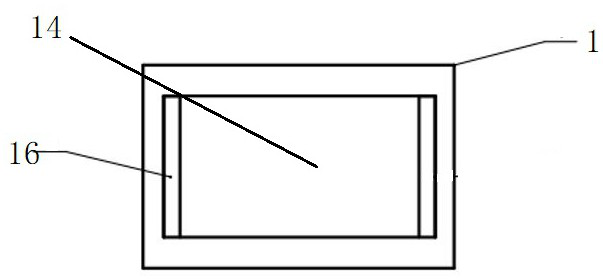

Manual inspection device for safety belt of vehicle

InactiveCN108946271AConvenient manual inspectionWind evenlyVehicle testingLabelling machinesLight sourceBelt safety

The invention discloses a manual inspection device for a safety belt of a vehicle. The manual inspection device comprises a rack, a conveying mechanism, an illuminating lamp and a label box, wherein the conveying mechanism is used for conveying the safety belt to the rack; the conveying mechanism, the illuminating lamp and the label box are all arranged on the rack; the conveying mechanism is usedfor rolling the safety belt; the illuminating lamp is used for providing a light source; the label box is used for providing a label for identifying flaw locations; the conveying mechanism comprisesan intermittent drive mechanism; and the intermittent drive mechanism is used for providing intermittent drive force to achieve the purpose that the conveying mechanism has a rotating state and a stopping state in a rotation period. A cylindrical surface on the outermost side of a locating turntable begins to be in contact with an arc-shaped locating groove in a driving turntable, so that the rotation of the driving turntable is stopped, the position of the driving turntable is located, a roller stops rotating, and the safety belt stops rolling to facilitate the manual inspection of the safetybelt.

Owner:滑县浩之本网络科技有限公司

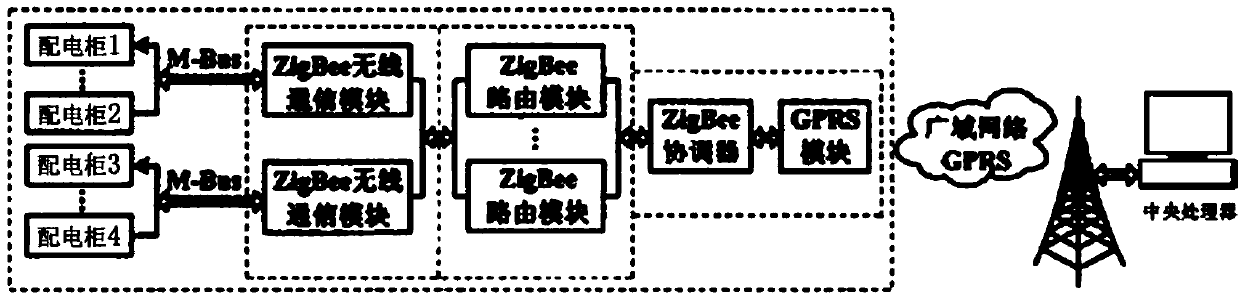

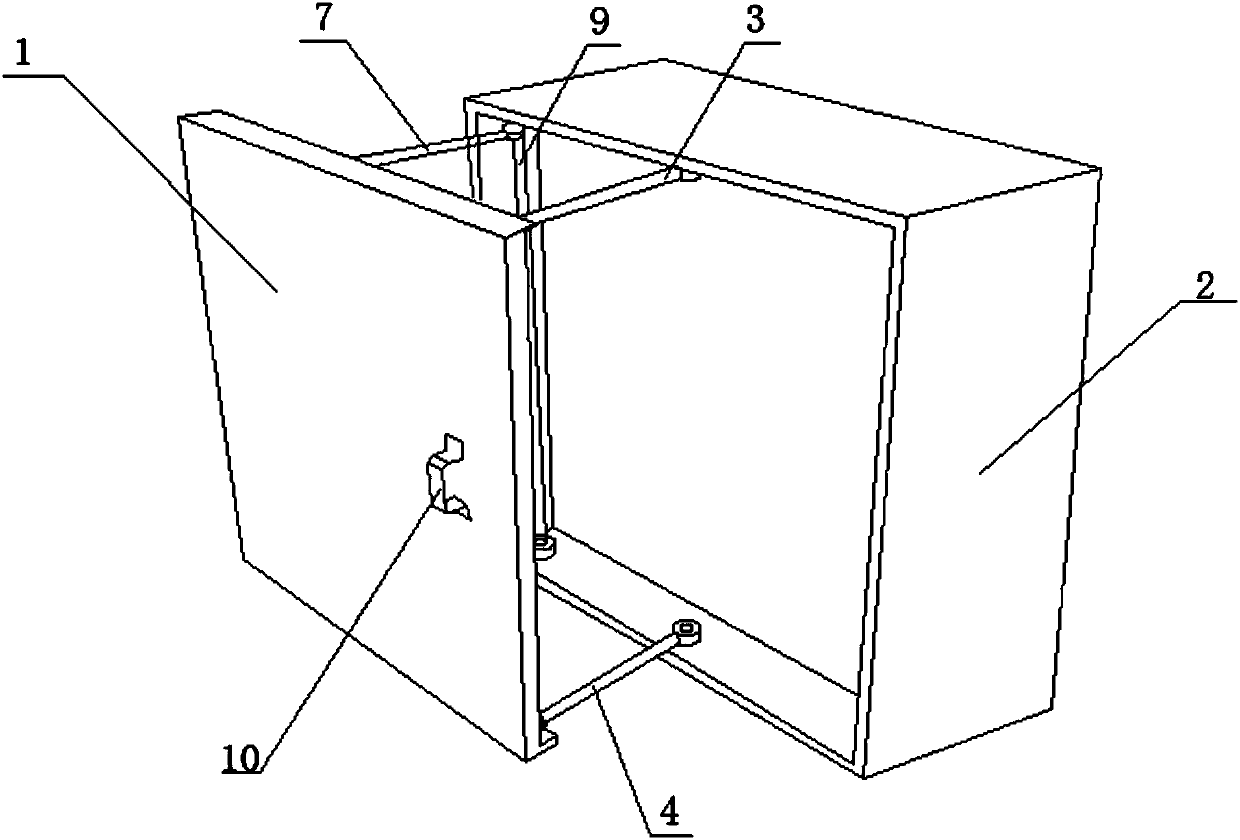

ZigBee-based integrated high-voltage power distribution cabinet monitoring system

InactiveCN107863696ARealize monitoring and managementImprove monitoring efficiencySubstation/switching arrangement detailsCircuit arrangementsElectricityMonitoring system

The invention discloses a ZigBee-based integrated high-voltage power distribution cabinet monitoring system, and belongs to the technical field of power distribution cabinets. The ZigBee-based integrated high-voltage power distribution cabinet monitoring system aims to solve the problem in the prior art that the monitoring efficiency of an integrated power distribution cabinet is low. The ZigBee-based integrated high-voltage power distribution cabinet monitoring system comprises a plurality of power distribution cabinets, an information collecting module, a monitoring platform, a ZigBee wireless communication module, a ZigBee routing module, a ZigBee coordinator, a GPRS module and a central processing unit. The information collecting module is installed in the power distribution cabinets.The information collecting module is electrically connected with the ZigBee wireless communication module. The ZigBee wireless communication module is electrically connected with the ZigBee routing module. The ZigBee routing module is electrically connected with the ZigBee coordinator. The ZigBee coordinator is electrically connected with the GPRS module. The GPRS module is connected with the central processing unit through a GPRS network. The central processing unit is electrically connected with the monitoring platform. The system is suitable for the integrated power distribution cabinet monitoring system.

Owner:四川东大恒泰电气有限责任公司

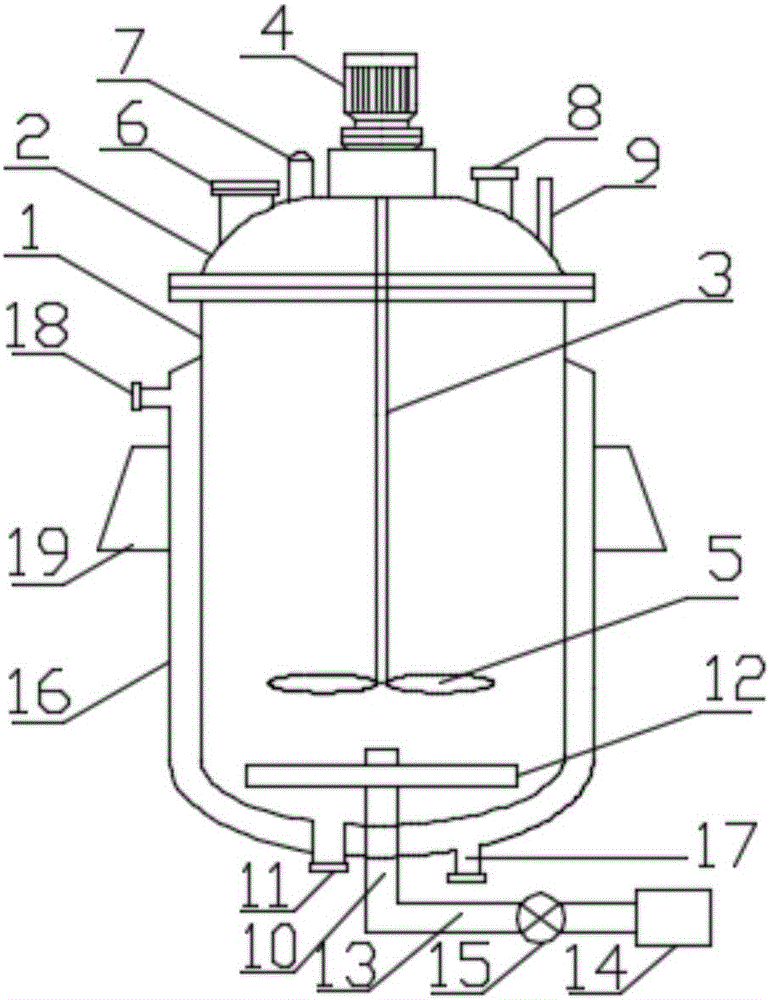

Multifunctional chlorination kettle

InactiveCN106140059AStable pressureWell mixedChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesEngineeringChlorine

The invention discloses a multi-functional chlorination kettle, which comprises a kettle body, a kettle cover, a stirring shaft and a motor. The upper part of the kettle cover is provided with an observation window, a lighting lamp, a feeding port and a return port, and the lamp head of the lighting lamp faces the kettle body. Inside, the bottom of the kettle body is provided with a chlorine gas inlet and a material outlet. The chlorine gas inlet is connected to a chlorine gas distributor, and the chlorine gas inlet is connected to a chlorine gas pipe with a heating device. The outer wall of the valve and the kettle body is provided with a jacket, the jacket is provided with a cooling water inlet and a cooling water outlet, and an ear-type support is arranged on the outer periphery of the jacket. The invention has a simple structure, and is equipped with a stirring device, which can accelerate the gas-liquid mixing in the kettle body and make the materials fully react; the lighting lamp is set on the kettle body, which is convenient for manual inspection of the working conditions inside the kettle body; the chlorine gas intake is automatically controlled by a regulating valve , can make the pressure in the kettle stable.

Owner:铜山县宏达精细化工厂

Detection device for detecting circuit board

ActiveCN102890233BImprove work efficiencyGood detachmentElectronic circuit testingEngineeringElectrical and Electronics engineering

Owner:GUANGZHOU CANLEAD ENERGY TECH CO LTD

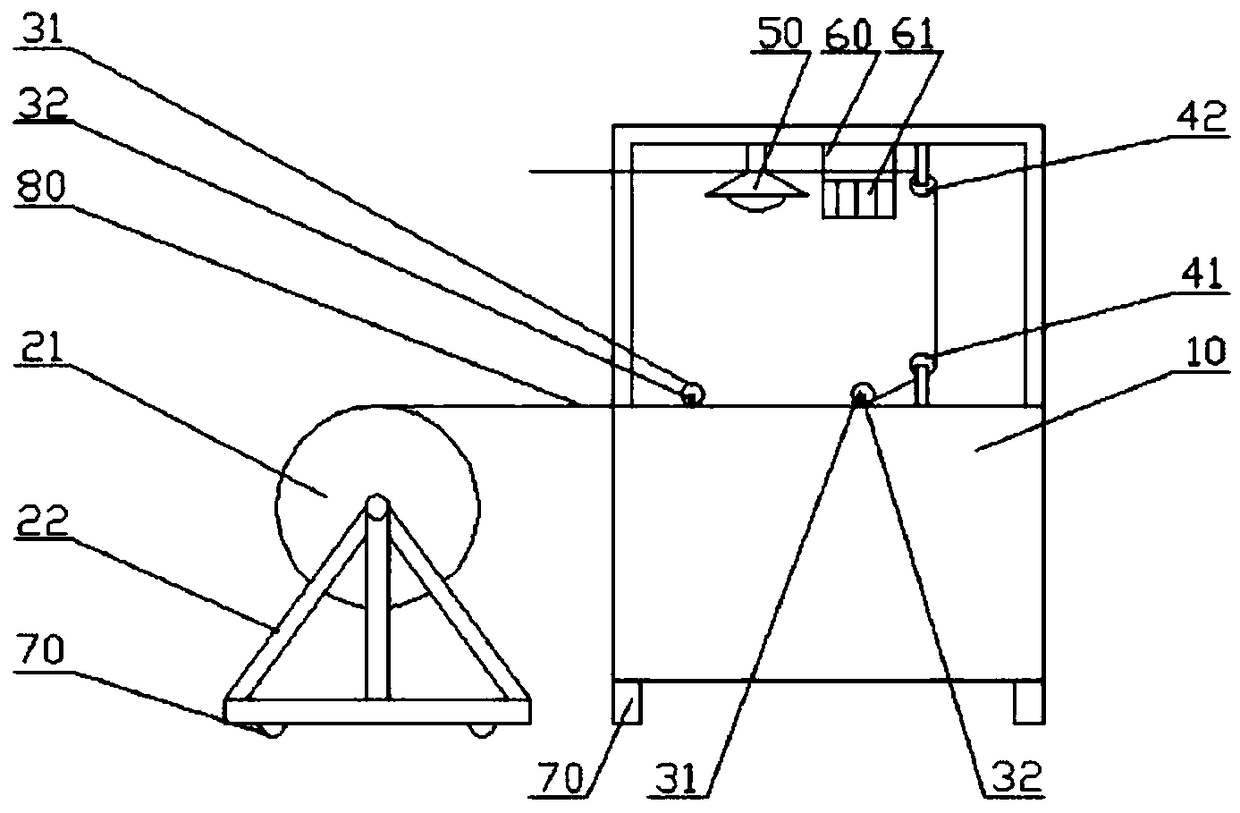

Robot logistics sorting system and its working method based on machine vision processing

ActiveCN109433627BAccurate identificationConvenient manual inspectionSortingMachine visionLogistics management

The invention discloses a manipulator logistics sorting system based on machine vision processing and a working method thereof. The manipulator logistics sorting system includes a computer, a camera device and a manipulator, the computer communicates with the manipulator through a wireless communication network, the camera device is arranged on a telescopic clamping claw of the manipulator, and the manipulator is installed on the base. According to the manipulator logistics sorting system based on machine vision processing and the working method thereof, since the openMV camera device is usedfor machine vision processing, bar codes on logistics express delivery can be identified and contained contents are obtained, the required express delivery can be very accurately identified and sortedout, obtained information can be transmitted to the computer for storage, and manual inspecting and recording are convenient; and since the openMV camera device is adopted, the sizes of objects and the current distance from the manipulator can be judged autonomously through captured pictures, the included angle of extension required by the clamping claw of the manipulator is autonomously calculated, the problem that traditional manipulators can only operate products with the same specification in flow is solved, and applicability is high.

Owner:DALIAN MARITIME UNIVERSITY

Semi-finished tire blank inspection device

The invention relates to a semi-finished tire blank inspection device, and belongs to the field of tire production. Guide rails are vertically fixed to the two sides in an outer frame, a lifting platform is installed between the two guide rails through sliding block bearings, a lifting driven shaft is fixed to the lower side of the lifting platform through two plummer blocks, gears are fixed to the two ends of the lifting driven shaft respectively, the lifting driven shaft is connected with a motor transmission shaft through a lifting chain, and the motor transmission shaft is driven by a lifting motor. A tire supporting box is installed on the upper portion of the inner side of the outer frame through a rotating shaft, a photoelectric sensor is installed at the bottom of the tire supporting box, a stand column is fixed to the center of the lifting platform, the upper end of the stand column is connected with the tire supporting box through a rotatable connecting piece, and a lower photoelectric sensor and an upper photoelectric sensor are arranged at the bottom end and the top end of the guide rail respectively; an air cylinder is arranged on one end of the lifting platform vertically; the top of a telescopic rod of the air cylinder is also provided with a rotatable connecting piece, and the lifting motor, the lower photoelectric sensor, the upper photoelectric sensor, a control device of the air cylinder and photoelectric sensors are connected with a PLC through signal lines.

Owner:TRIANGLE TIRE

Portable building board surface detection device

PendingCN114166738AEfficient Surface Scratch DetectionCompact structureUsing mechanical meansMaterial analysisArchitectural engineeringStructural engineering

The invention relates to a portable building board surface detection device which is provided with a seat plate, a supporting plate and a sliding rail are arranged on the upper side and the lower side of the seat plate respectively, a sliding block is slidably connected to the sliding rail, a scraping assembly is arranged on the sliding block, and the scraping assembly comprises a transverse plate, a grip, a guide column, a spring, a triangular scraper and a tool apron. The multiple triangular scrapers are fixedly connected with the tool apron, an L-shaped positioning block, a cushion block, a locking plate and a side plate are arranged on the right side of the base plate, a lead screw is arranged on the side plate, the locking plate is slidably connected with the base plate, and the lead screw penetrates through the side plate to be rotatably connected with the locking plate. A connecting seat is arranged on the left side of the seat plate, and a locking screw is arranged on the transverse plate. The building board surface scratch detection device has the advantages of being capable of efficiently conducting surface scratch detection on building boards, small and exquisite in structure, convenient to carry and convenient to conduct manual detection.

Owner:昆山正信检测有限公司

Non-mirror symmetrical two-dimensional code logo graphic verification and layout method for monocular vision positioning

ActiveCN107578078BHas non-mirror symmetryIncrease the number of digitsImage analysisRecord carriers used with machinesGraphicsMirror reflection

The invention relates to a non-mirror-symmetry two-dimensional code marking figure verification and layout method for monocular vision location. The problems that in the prior art, when there are toomany data bits and a camera is low in precision, recognition can not be conducted, data inspection and verification can not be manually conducted, and dislocation caused by wrong two-dimensional codesare formed under the mirror condition are solved. Compared with two-dimensional code marking figures obtained through other methods, the method is simple in layout and easy to implement, data codes and verification codes are separated, and manual inspection and verification are convenient; meanwhile, the number of bits of data codes is increased, and the total number of available codes in the system is greatly increased. Two-dimensional code marking figures produced through the method have non-mirror-symmetry and are suitable for the environment with large-area mirror reflection conditions. The method is used for the field of monocular camera vision location.

Owner:HARBIN INST OF TECH

Part conveying for selection mechanism capable of moving leftwards and rightwards in transverse direction

InactiveCN108689084AGood effectConvenient manual inspectionConveyorsConveyor partsEngineeringMachine parts

The invention discloses a part conveying for selection mechanism capable of moving leftwards and rightwards in the transverse direction. The part conveying for selection mechanism comprises a machineframe; the machine frame comprises a lower supporting transverse plate; supporting legs are fixed to the front wall surfaces and the rear wall surfaces of the left portion and the right portion of thelower supporting transverse plate; upper supporting transverse beams are fixed to the top surfaces of the two supporting legs of the front portion and the top surfaces of the two supporting legs of the rear portion; and a main top plate presses and abuts against the top surfaces of the two upper supporting transverse beams, and baffles are fixed to the front portion and the rear portion of the top surface of the main top plate. The part conveying sorting mechanism can be connected with other conveying mechanisms, the main top plate can be transversely moved leftwards and rightwards, accordingly, the effect that the part conveying sorting mechanism cooperates with the conveying mechanisms on the two sides is ensured, and machined parts needing to be detected are directly placed on a conveying belt through other conveying parts; and when the machined parts needing to be detected move to a certain position, through operation of a pushing cylinder, the to-be-detected parts can be pushed to a material receiving place from the conveying belt, manual detection is facilitated, product frames do not need to be carried, the labor amount of workers is greatly decreased, and the effect is good.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com