Semi-finished tire blank inspection device

A technology for inspection devices and semi-finished products, applied in measuring devices, automobile tire testing, transportation and packaging, etc., can solve problems affecting the quality of finished tires, difficulty in tire embryo turning, and insufficient detection, so as to save waiting time for tire unloading and labor Inspection is convenient and the effect of inspection efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

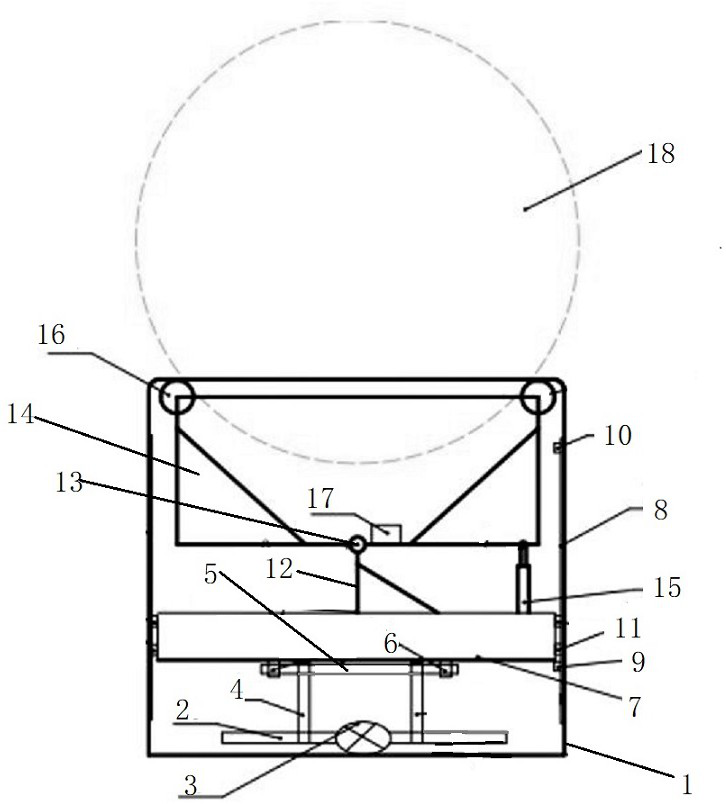

[0011] Such as figure 1 and figure 2 , an outer frame 1 is provided, and guide rails 8 are vertically fixed on both sides inside the outer frame 1, and a lifting platform 7 is installed between the two guide rails 8 through slider bearings 11, and the lower side of the lifting platform 7 is passed through two seated bearings 6 A lifting driven shaft 5 is fixed, and a gear is fixed at both ends of the lifting driven shaft 5. The lifting driven shaft 5 is connected to the motor transmission shaft 2 through the lifting chain 4. The motor transmission shaft 2 is driven by the lifting motor 3. The outer frame 1 The upper part of the inner side is equipped with a tire support box 14 through the rotating shaft. The size of the tire support box 14 can be replaced according to the size of the tire blank 18 to be checked. A photoelectric sensor 17 is installed at the bottom of the tire support box 14. The center position of the lifting platform 7 is fixed with a column 12. The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com