Detection device for detecting circuit board

A detection device and circuit board technology, applied in electronic circuit testing and other directions, can solve the problems of difficult circuit board detection, low manual detection efficiency, damage to electronic devices, etc., to avoid poor contact, tight and firm contact, and not easy to shift. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

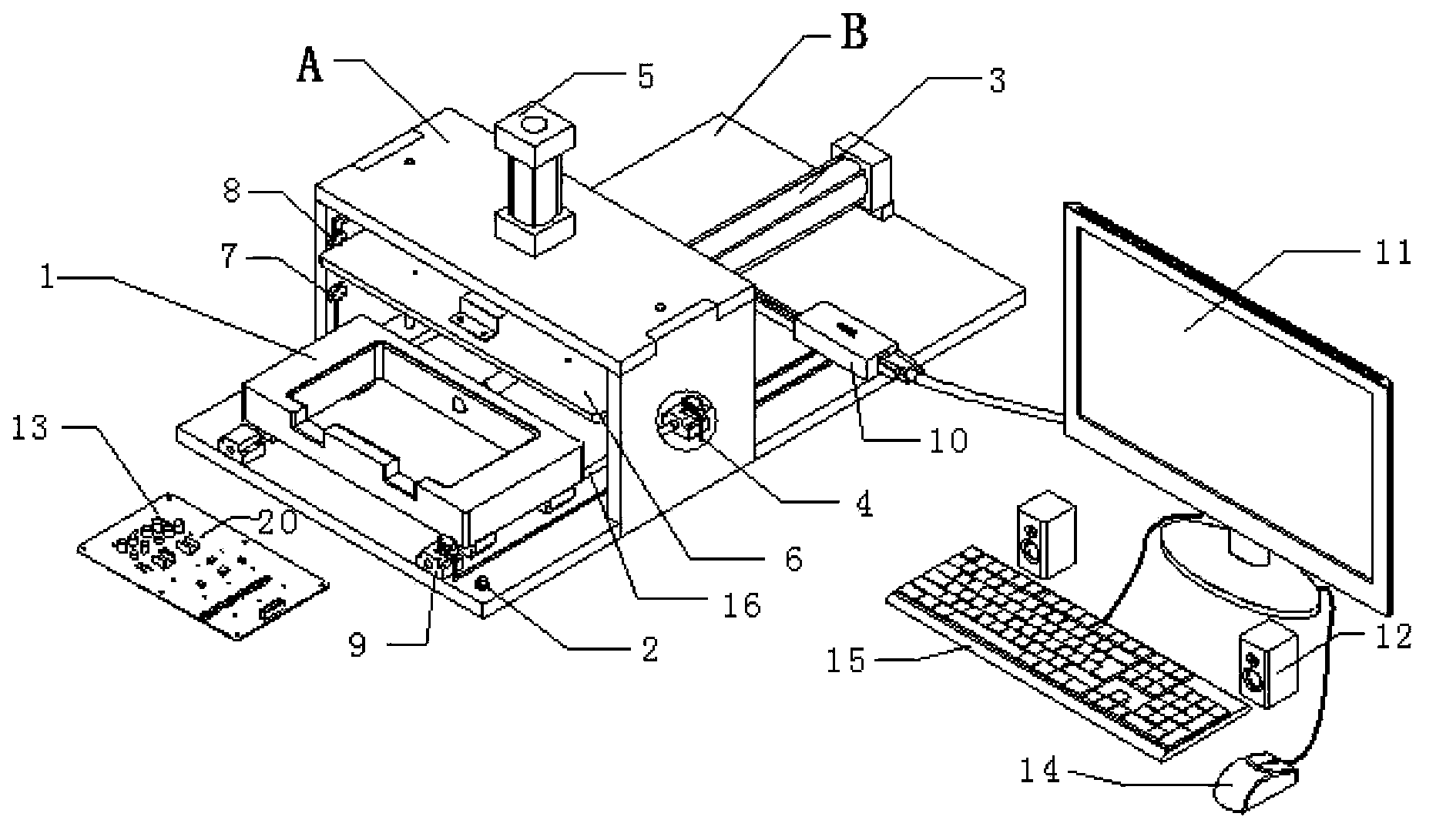

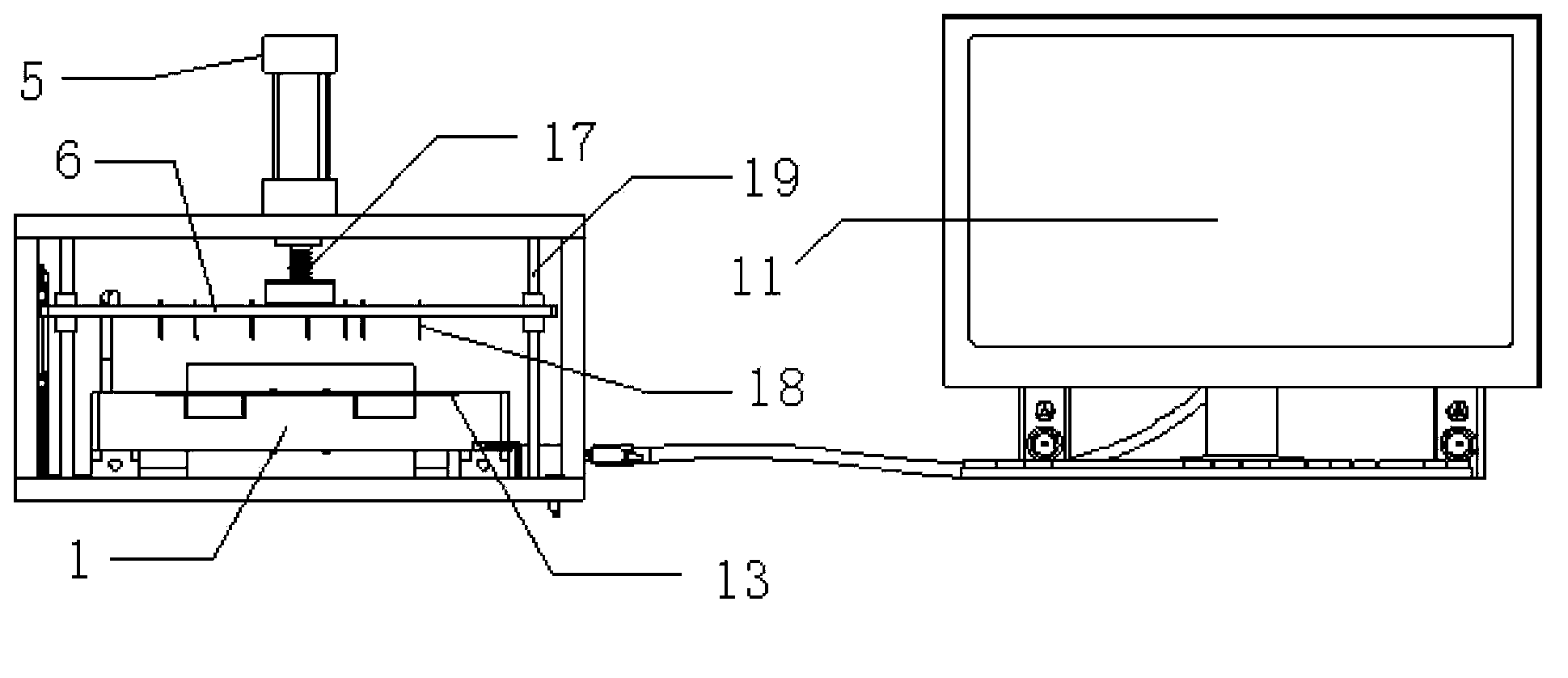

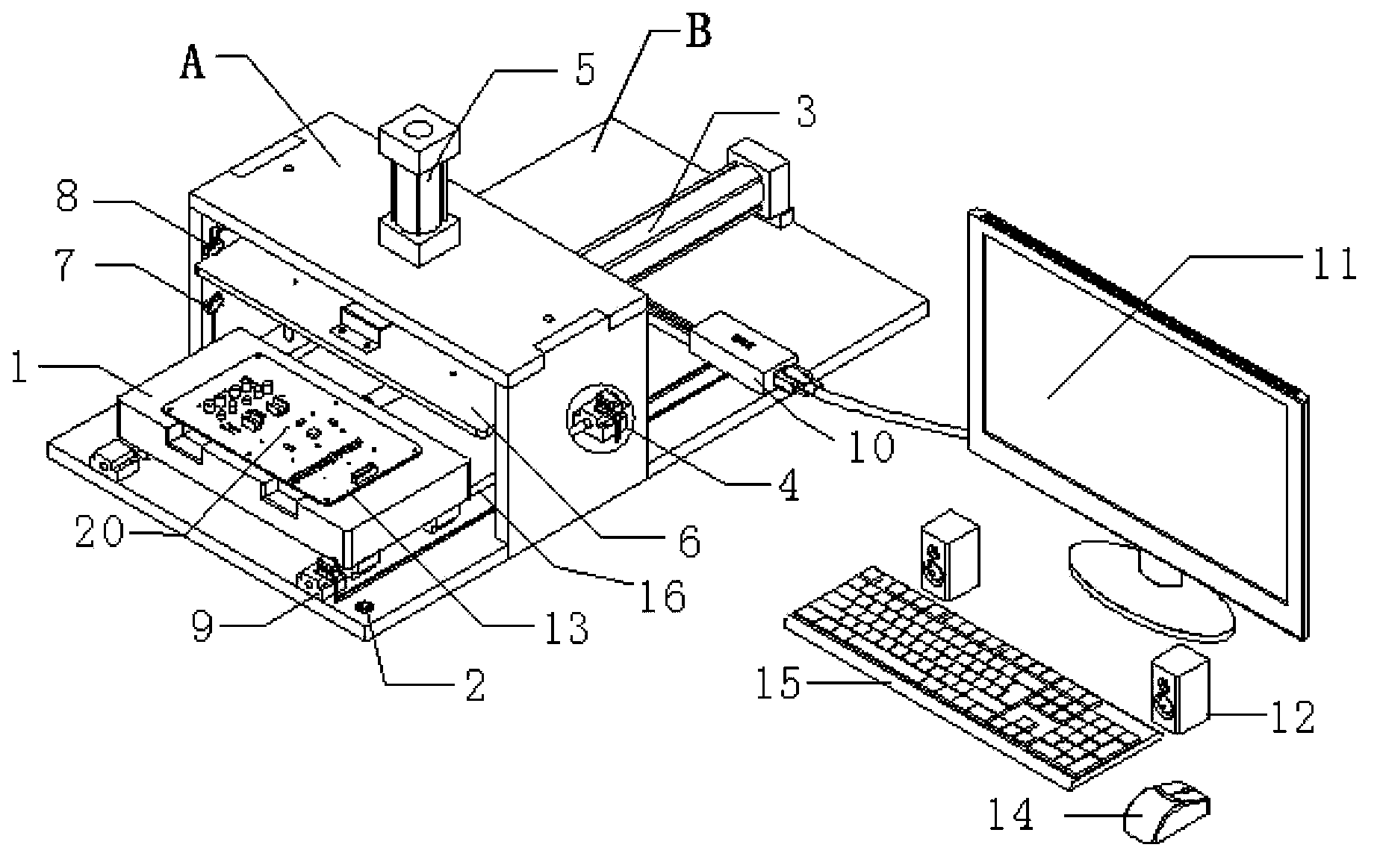

[0030] Examples of the present invention are figure 1 and 2 As shown, it includes a base, a single-chip microcomputer 10 (i.e. a processor), a display 11, a speaker 12, a mouse 14 and a keyboard 15; , and the detection platform A is equipped with a track column 19, a detection plate 6, a master cylinder 5, an upper travel switch 8 and a lower travel switch 7.

[0031] Described track post 19 passes through detection board 6 and is connected between detection table A and base plate B, and master cylinder 5 is arranged on the top of detection table A, and master cylinder 5 passes through the top of detection table A and detects board 6 Then, the detection board 6 is driven to move up and down on the track column 19; in addition, the upper travel switch 8 and the lower travel switch 7 are arranged on the side wall of the detection table A, and the upper travel switch 8 It is placed at the upward movement limit position of the detection plate 6, and the lower travel switch 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com