Apparent defect detection method for touch screen protective glass

A technology for protecting glass and appearance defects, which is applied in optical testing for flaws/defects, measuring devices, and material analysis by optical means. The effect of fast, low missed detection rate and consistent detection standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

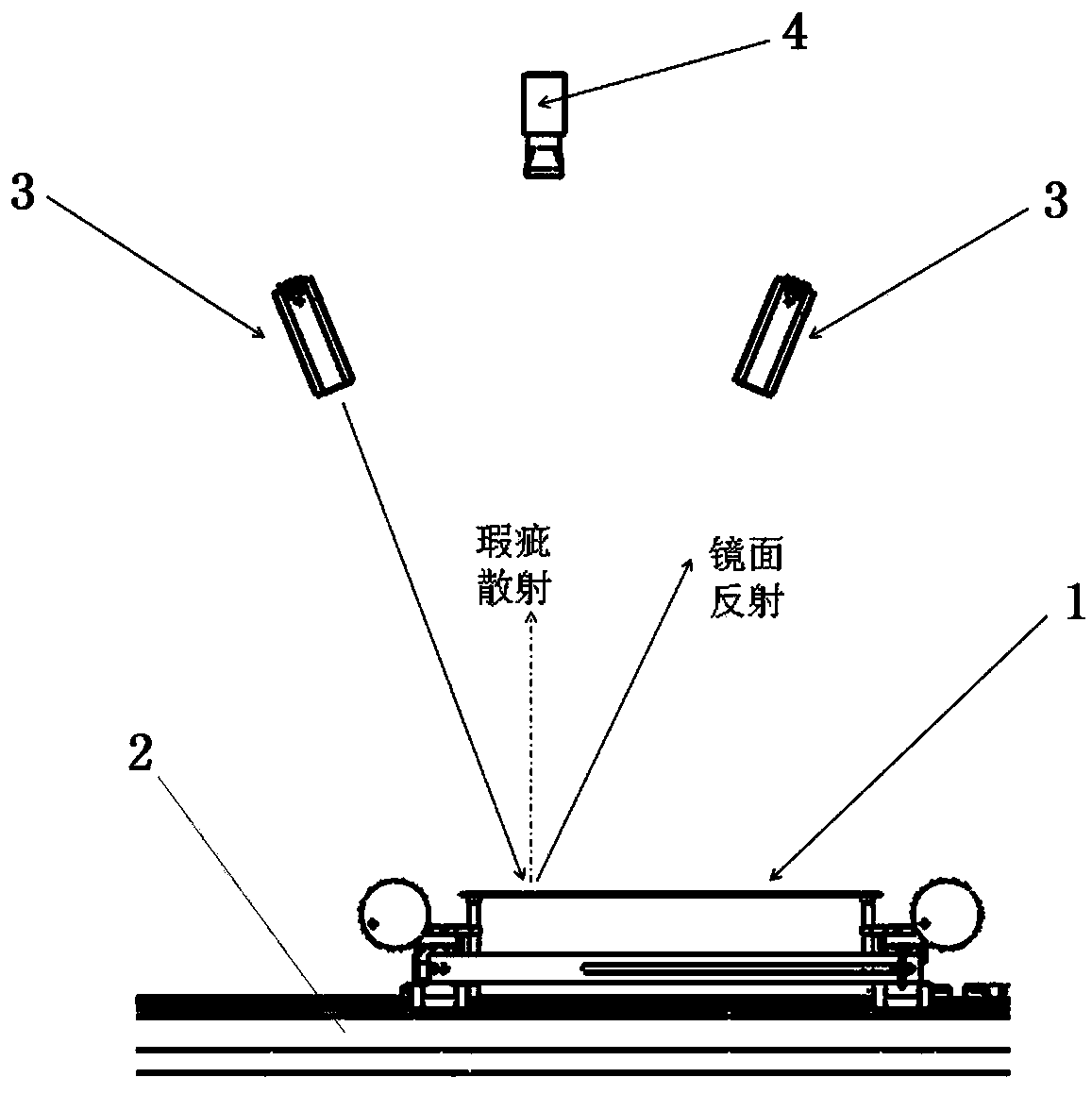

[0020] figure 1 An embodiment of the method for detecting the appearance defect of the protective glass of the touch screen of the present invention is shown, which includes the following steps:

[0021] 1) Place the glass sample to be tested on a sample conveying device 1, the sample conveying device 1 can drive the sample to move linearly on the guide rail 2, and two illumination light sources 3 are arranged above the sample conveying device 1, and Take a camera 4;

[0022] 2) Move the sample conveying device 1 to transfer the glass samples placed on the sample support frame to the front camera 4 in turn;

[0023] 3) The front camera 4 captures the image of the surface of the glass sample, and the image data is transmitted to the computer;

[0024] 4) Finally, the computer program completes the image processing and analyzes the defect information of the sample.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com