Manual inspection device for safety belt of vehicle

An inspection device and seat belt technology, which is applied in the field of manual inspection of vehicle seat belts, can solve problems such as product defects and undiscovered defects, hidden quality problems, and easy fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

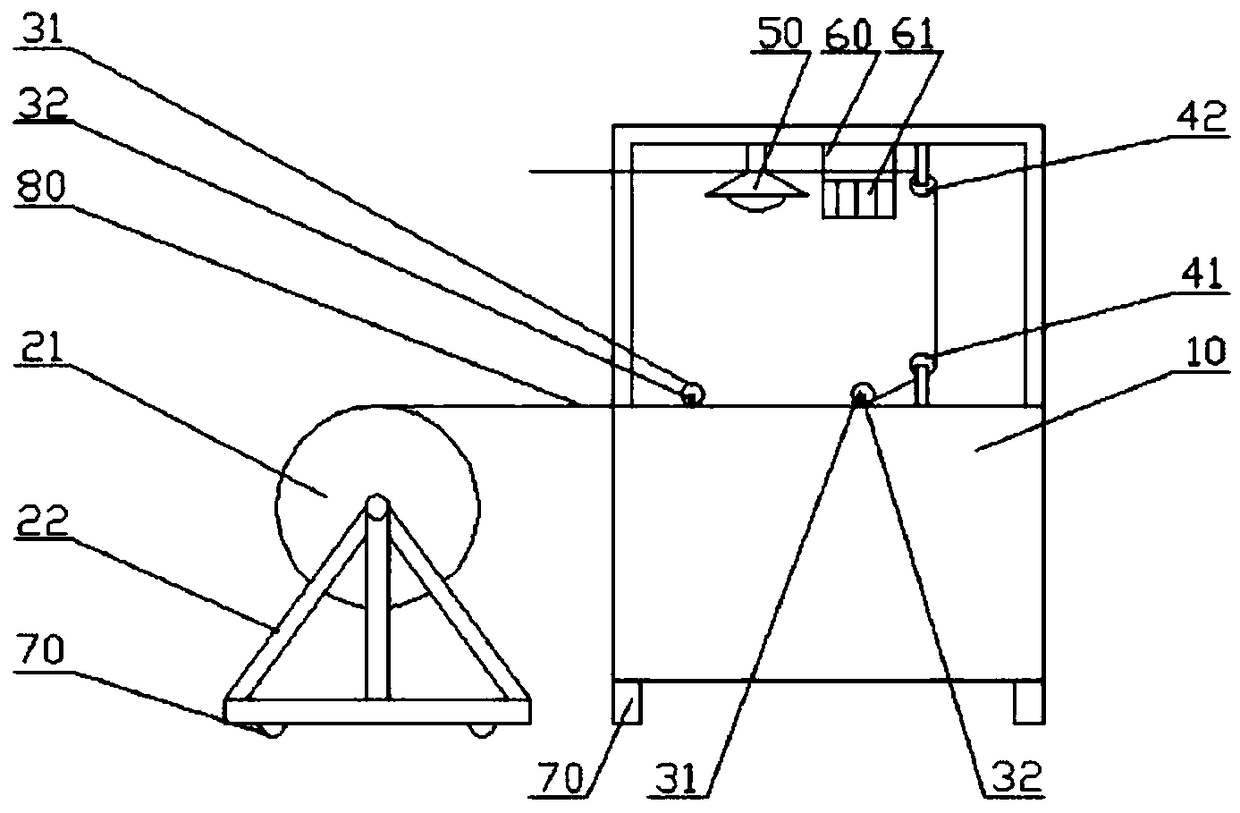

[0030] A safety belt manual inspection device for vehicles, which includes a frame, a conveying mechanism for transporting seatbelts to it, a lighting lamp and a label box, and the conveying mechanism, lighting lamp and label box are all arranged on the frame, and the The conveying mechanism is used to wind up the safety belt, the lighting lamp is used to provide a light source, and the label box is used to provide a label for identifying the position of the defect, and the conveying mechanism includes an intermittent transmission mechanism, and the intermittent transmission mechanism is used for Intermittent driving force is provided to realize the rotation state and stop state of the conveying mechanism within one rotation cycle.

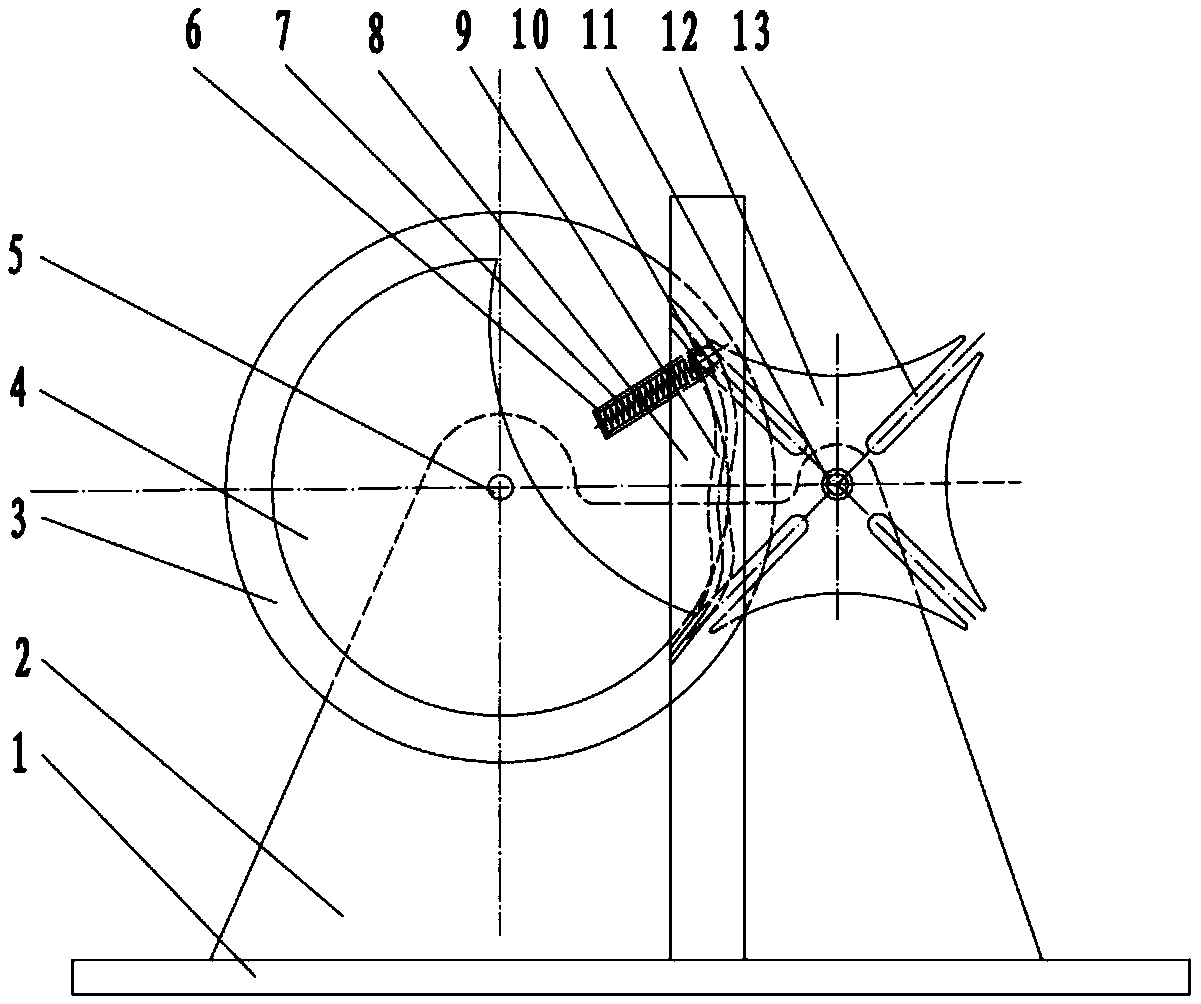

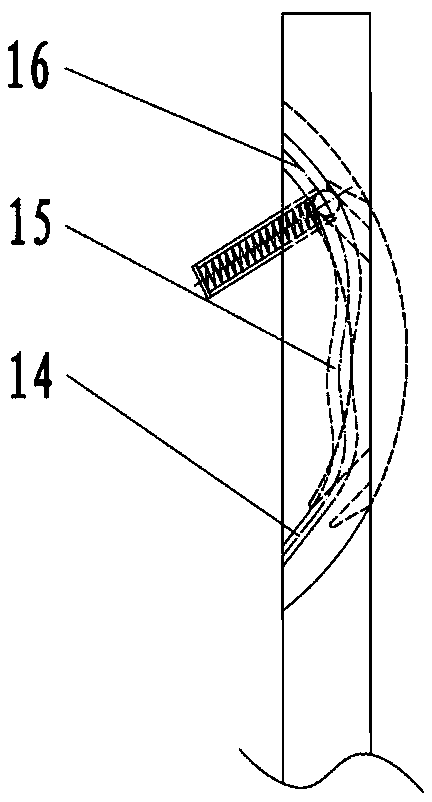

[0031] Such as Figure 2-3 As shown, the intermittent transmission mechanism includes a base plate 1, a bracket 2, a driving turntable 3, a positioning turntable 4, a first rotating shaft 5, a spring support frame 6, a spring 7, a guide frame 8, a...

Embodiment 2

[0042] A safety belt manual inspection device for vehicles, comprising a frame and a conveying mechanism for transporting seat belts thereto, lighting lamps and label boxes, the conveying mechanism, lighting lamps and label boxes are all arranged on the frame, the The conveying mechanism is used to wind up the safety belt, the illuminating lamp is used to provide a light source, and the label box is used to provide labels for identifying defect positions. The conveying mechanism includes an intermittent transmission mechanism, and the intermittent transmission mechanism is used to provide Intermittent driving force is used to realize the conveying mechanism having two rotation states and two stop states within one rotation cycle.

[0043] Such as Figure 2-3 As shown, the intermittent transmission mechanism includes a base plate 1, a bracket 2, a driving turntable 3, a positioning turntable 4, a first rotating shaft 5, a spring support frame 6, a spring 7, a guide frame 8, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com