Magnet detecting device of magnet automatic assembling machine

A technology of inspection device and assembly machine, applied in measuring device, electric/magnetic exploration, manipulator, etc., can solve the problems of affecting the use effect of products, low work efficiency, difficult process of installing magnets, etc., so as to facilitate detection and timely troubleshooting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments, and similar reference numerals in the drawings represent similar components.

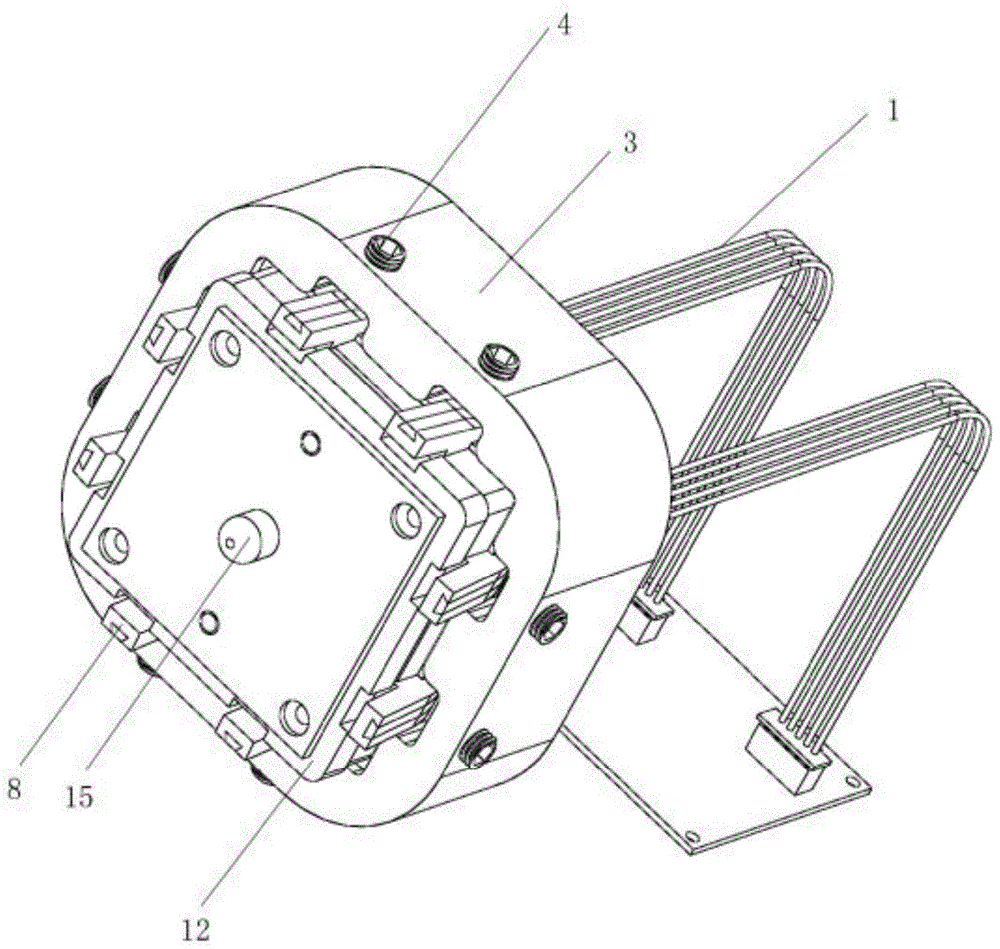

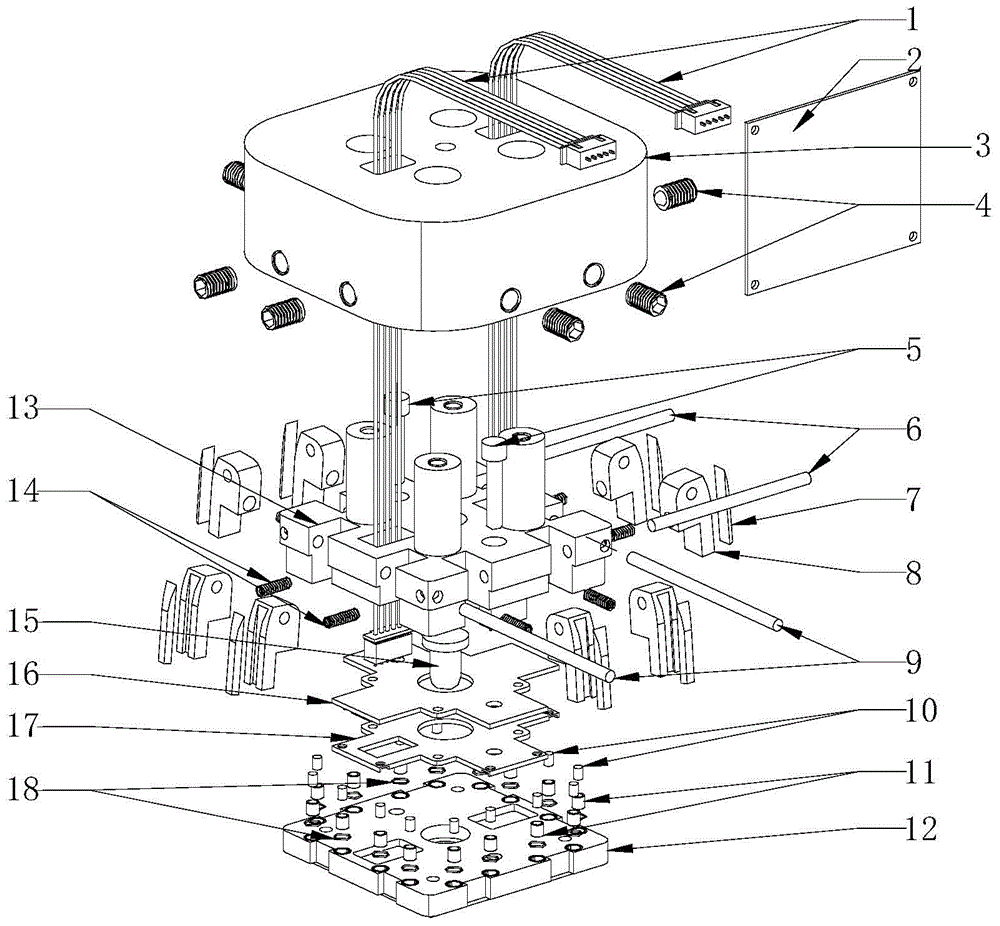

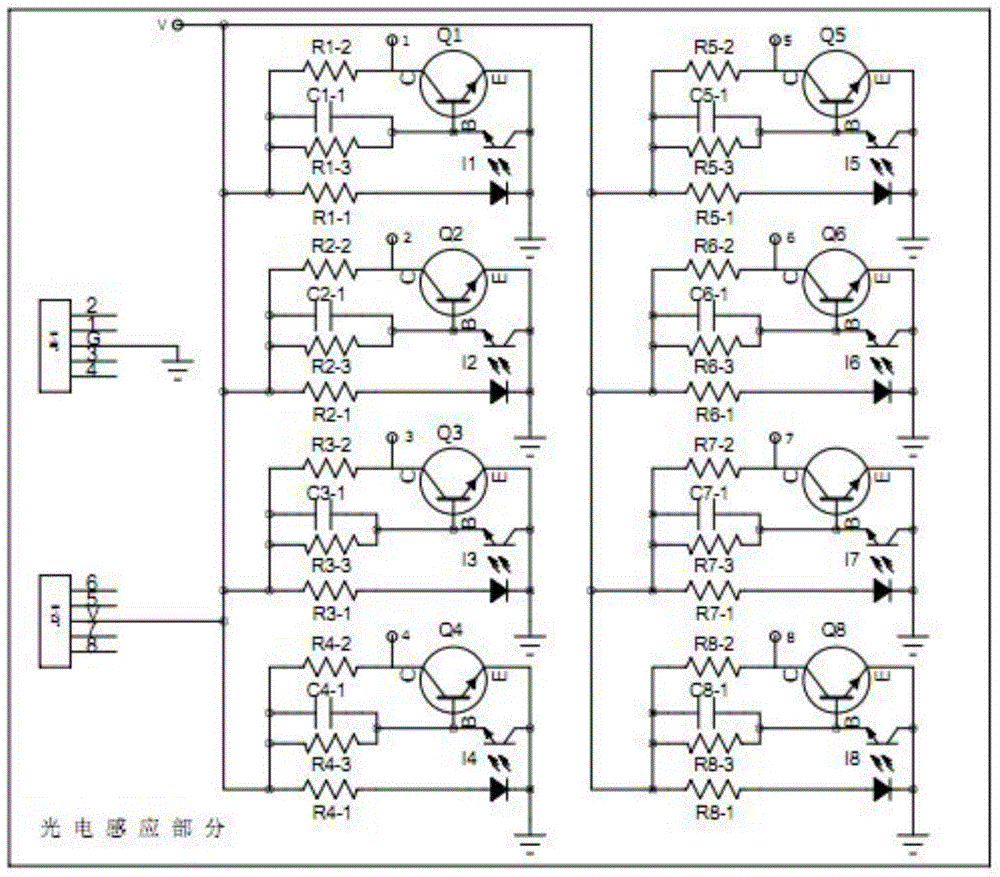

[0014] Such as Figure 1-2 As shown, the magnet inspection device of the magnet automatic assembly machine of the magnetic toy disclosed in the present invention, the magnet inspection device is installed on the assembly manipulator of the magnet automatic assembly machine, and the assembly manipulator magnet inspection device is provided with gripper limit block 3, gripper Fixing seat 13, gripper 8, gripper hinge pin 6 and magnet limit block 12, gripper hinge pin 6 hinges gripper 8 on gripper holder 13, and magnet stopper is installed at gripper holder 13 lower ends 12. A plurality of magnet limit slots are provided on the magnet limit block 12. The magnet inspection device is installed between the gripper holder 13 and the magnet limit block 12 of the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com