Collaborative fault simulation system of high-speed train information control system

A technology for information control and high-speed trains, applied in the general control system, control/regulation system, test/monitoring control system, etc., can solve the problems of unsatisfied, affected and isolated effective control, and cannot approach the occurrence, development, and evolution of the evolution environment problems such as the complex space-time change characteristics, and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples.

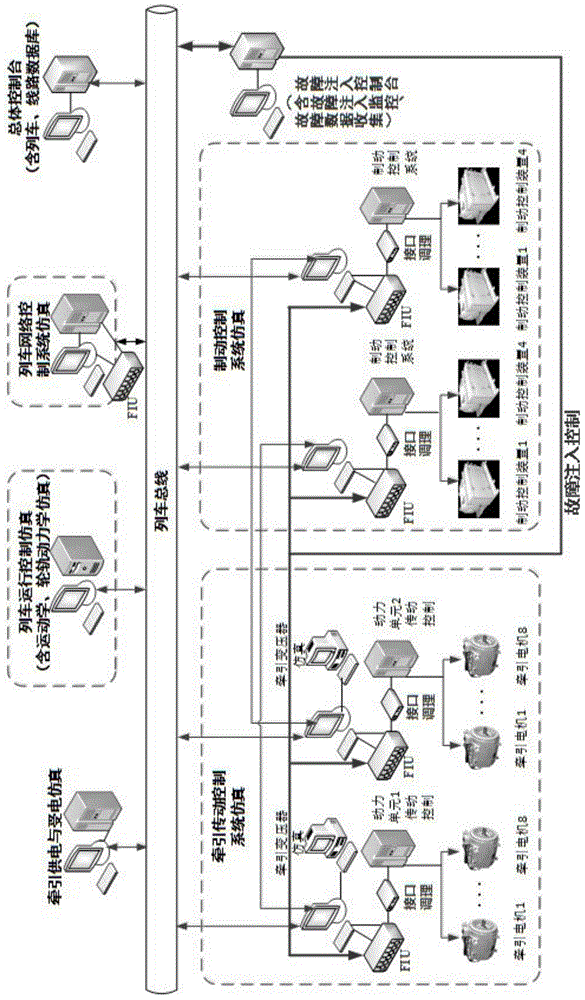

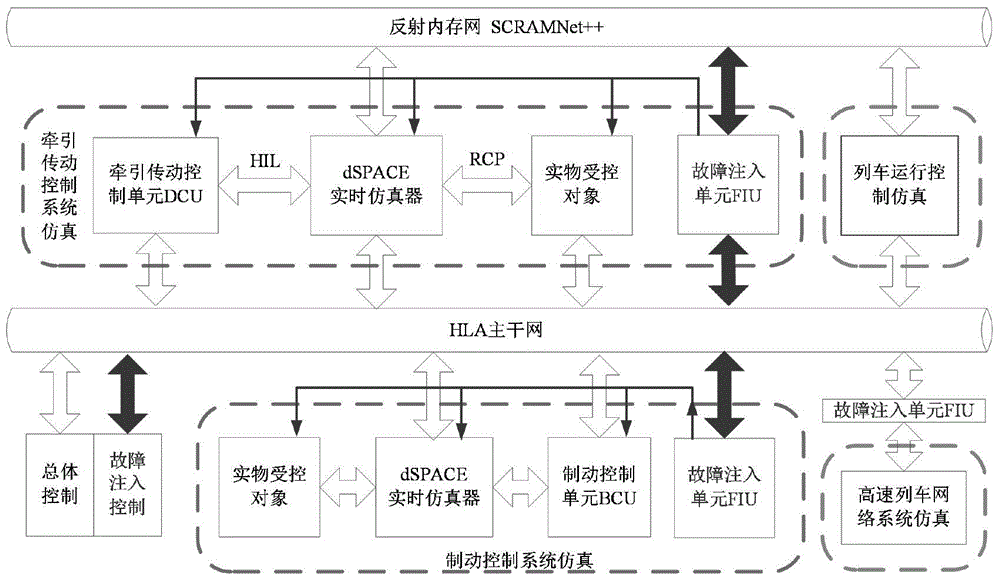

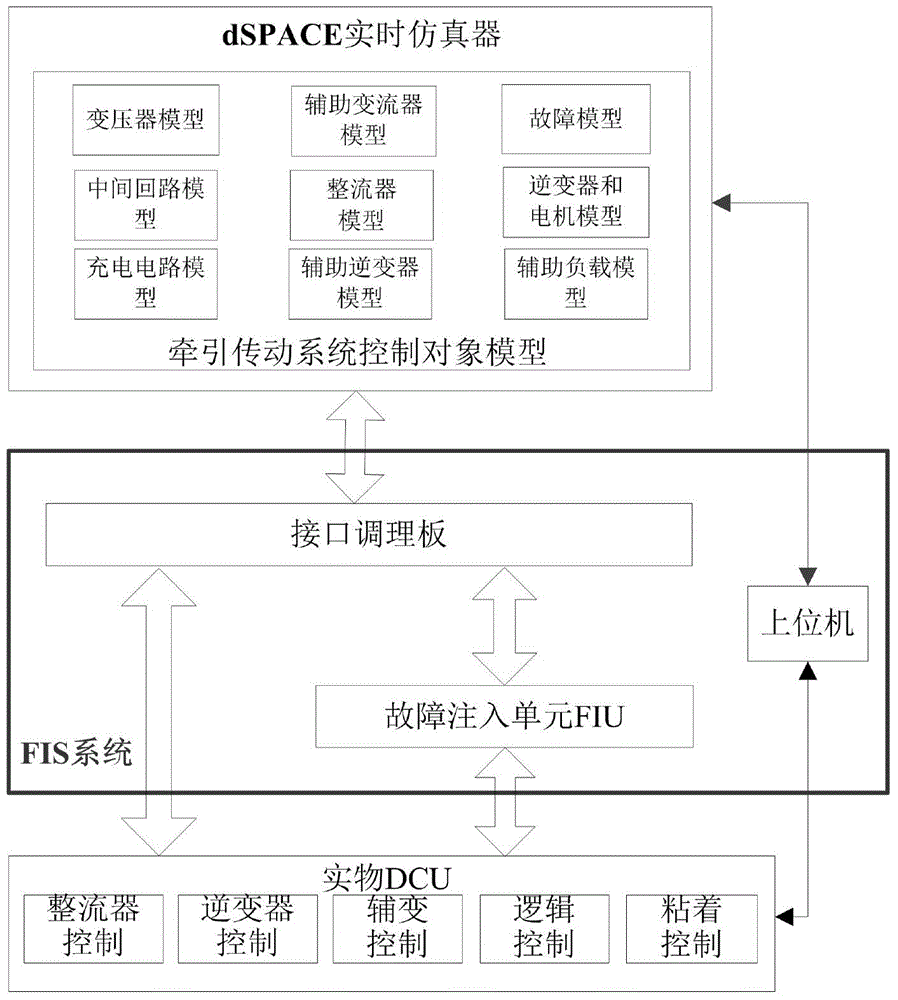

[0025] The high-speed train information control system includes traction drive control system, network control system, brake control system, train operation control system and other systems. The collaborative fault simulation system can realize the simulation analysis and verification of fault modeling, fault injection / simulation, fault propagation impact and isolation, fault diagnosis and simulation credibility evaluation of high-speed train information control system. figure 1 A schematic diagram of the collaborative fault simulation system of the high-speed train information control system is given. The collaborative fault simulation system includes a real-time simulation computer, a real-time simulation control network, and system physical effect simulation equipment.

[0026] The real-time simulation computer includes the overall console, the fault in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com