Middle Motor with Variable Reduction Ratio for Electric Bicycle

A technology of electric bicycles and mid-mounted motors, applied to bicycles, motor vehicles, electromechanical devices, etc., to achieve the effects of strong climbing ability, stable and reliable force transmission, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

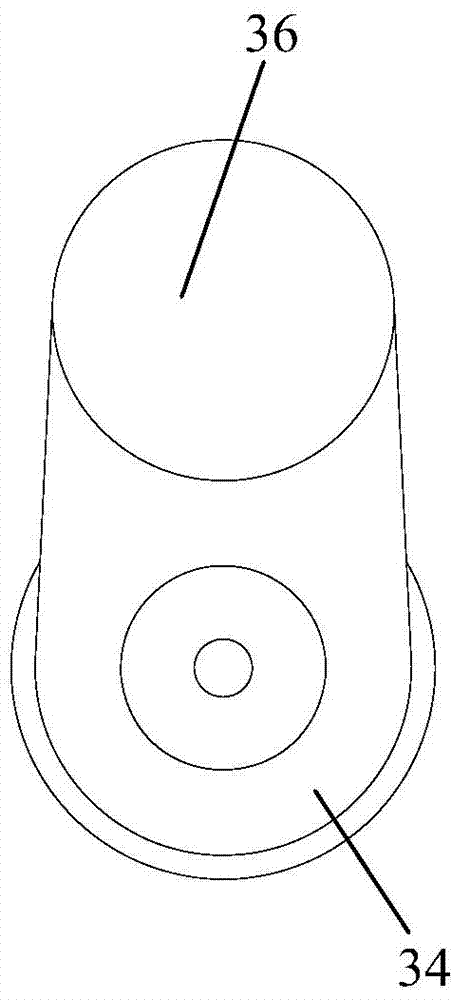

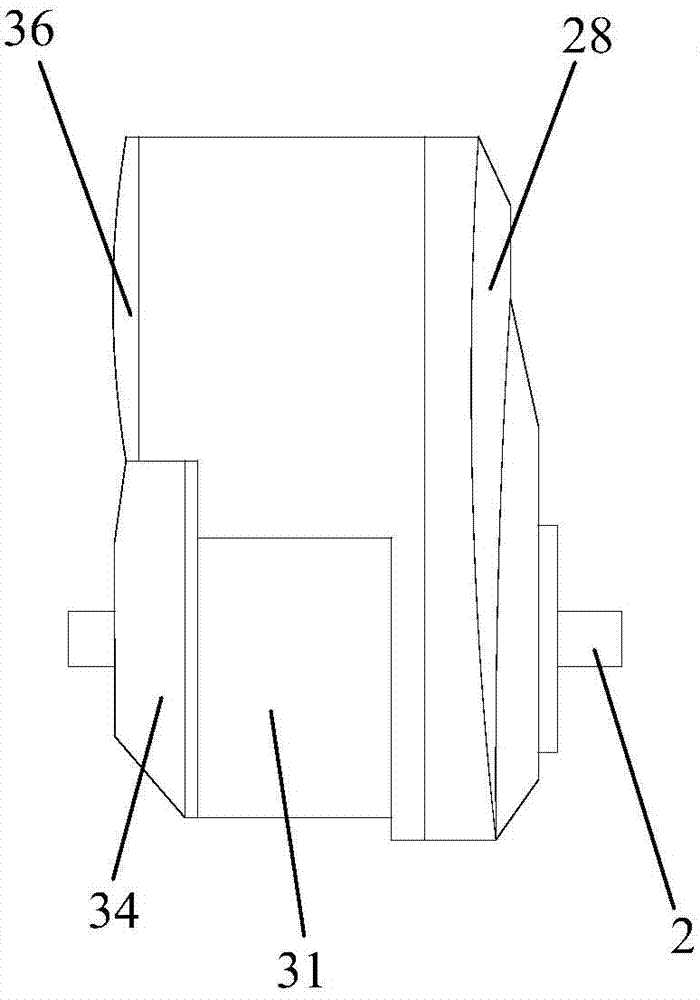

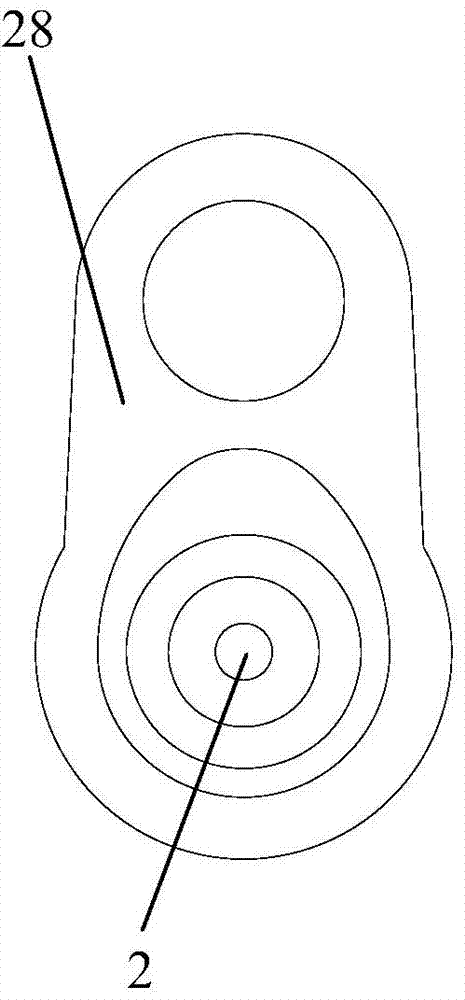

[0024]See the accompanying drawings for details. Compared with the prior art, the present invention provides a middle motor with a variable reduction ratio for an electric bicycle, including a housing, a motor 3, a primary pinion 5, a primary gear 6, two Stage pinion 7, stage two bull gear 8 and power output sleeve 24, described stage one pinion is keyed on the motor output shaft 4, and described stage one pinion meshes with stage one bull gear, and the stage one stage bull gear The secondary small gear of the shaft meshes with the secondary large gear, the primary large gear and the secondary small gear are keyed to the gear support shaft 9, and the gear support shaft passes through the right gear support bearing 10 and the left gear support bearing 10-1 respectively It is supported on the right side case 28 and the middle case 31 . The inner ring of the power output sleeve 24 is supported by the support bearing 30 of the power output sleeve, and its outer ring is supported o...

Embodiment 2

[0027] On the basis of Embodiment 1, a three-stage reduction gear is added, and the housing of the middle motor can be directly inserted into the bottom bracket 51, and the bottom bracket connection part 31-1 of the middle casing runs through the main shaft, and is connected through the bottom bracket of the middle casing. The support bearing 49 on the right side of the part, the support bearing 49-1 on the left side of the five-way connection part of the middle shell, the left support bearing is locked with the bearing lock nut 50, and the middle shell is connected with the five-way lock by the five-way lock nut 52 tight. Embodiment 2 is suitable for existing ordinary bicycles, and ordinary bicycles can be converted into electric bicycles under the condition that the frame structure of the whole vehicle remains unchanged.

[0028] Specifically optimize the structure, the middle output ring of the double-layer one-way overrunning clutch is fixedly connected with a three-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com