Wheel hub motor with variable reduction ratio for electric bicycle

A technology for electric bicycles and reduction ratios, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of electric bicycle endurance, starting, and climbing ability at the same time, so as to expand the range of optimal efficiency and save power The effect of cruising distance and maintaining battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

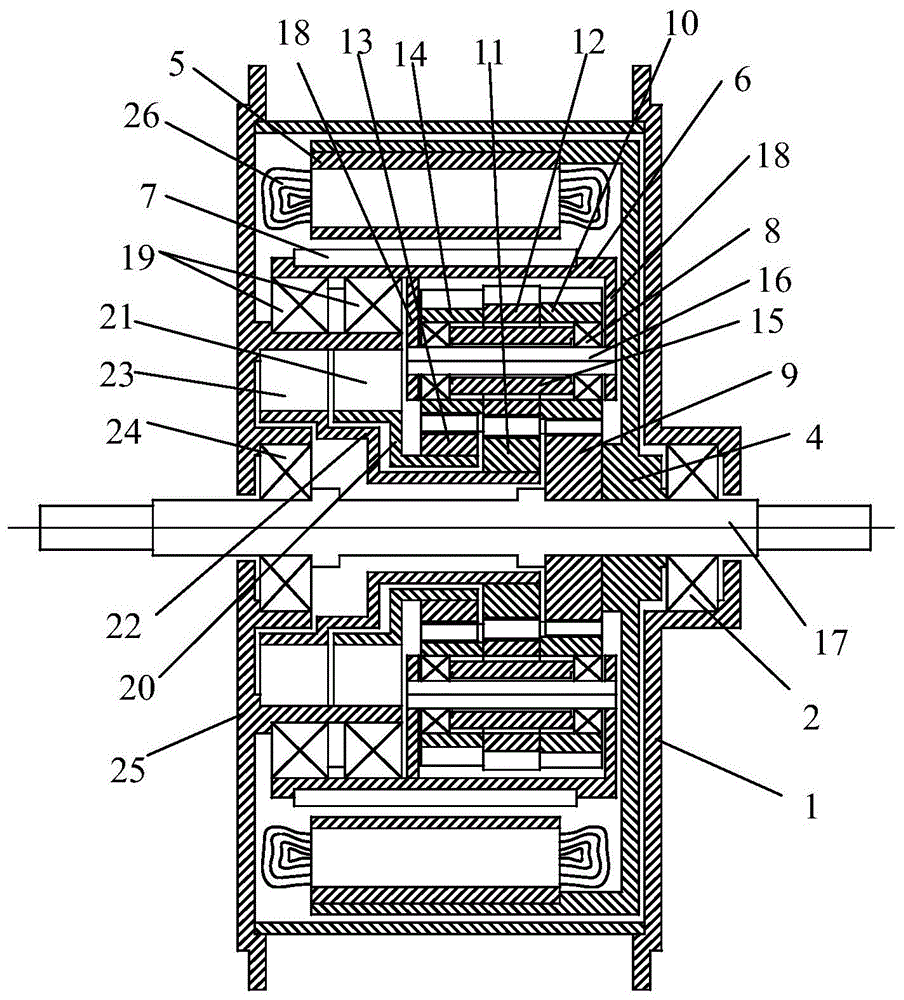

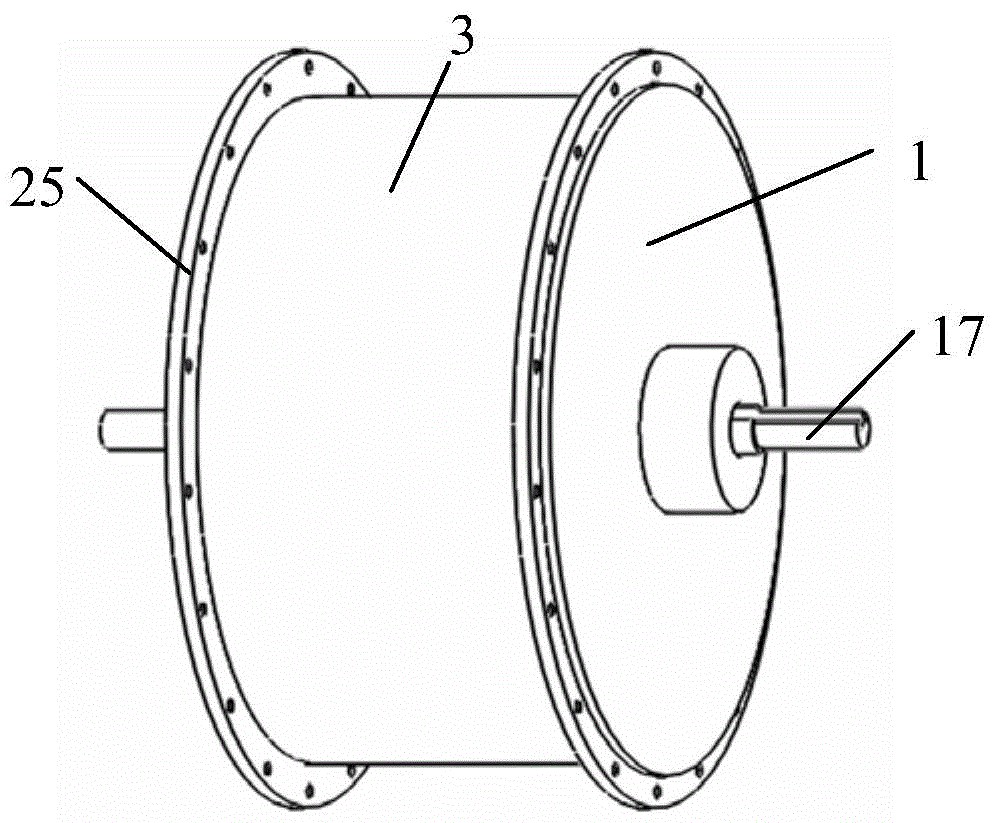

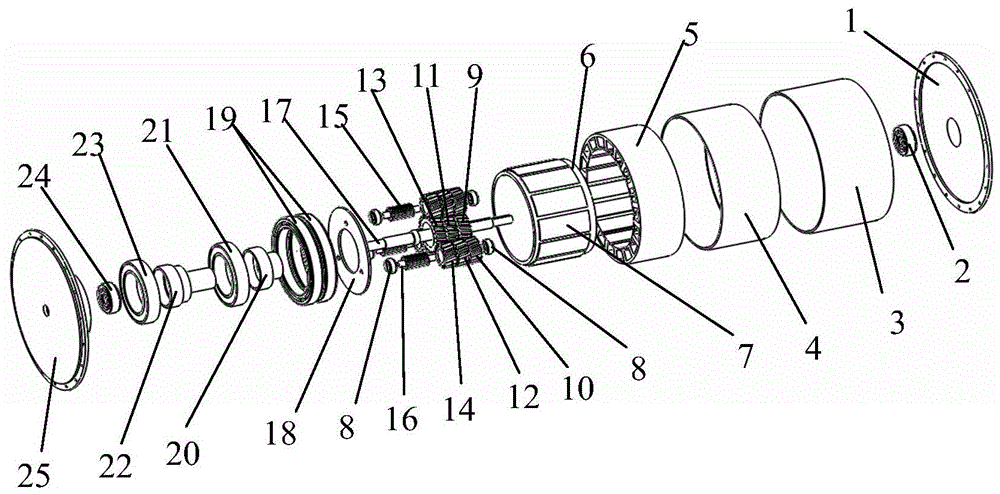

[0031] see attached Figure 4 , attached Figure 11 , the differential planetary gear reduction mechanism includes a rotor 6, a planet carrier 18, several magnets 7, a first sun gear 9, three first planet gears 10, a second sun gear 11, three second planet gears 12, The third sun gear 13, three third planetary gears 14, the second sun gear output sleeve 22, the third sun gear output sleeve 20, the large reduction ratio output one-way overrunning clutch 23, the small reduction ratio output one-way overrunning clutch 21, The first sun gear is keyed to the main shaft, and the main shaft 17 is supported on the left and right hub housings 25, 1 through the left and right hub housing bearings 24, 2 respectively, and the left and right hub housings 25, 1 and the intermediate housing 3 form an integral hub housing . The rotor is supported on the left side hub shell through the rotor support bearing 19, the magnet is fixed on the outer circumference of the rotor, and the planetary wh...

Embodiment 2

[0035] see attached Figure 5 , attached Figure 12, the rotor is supported on the left hub shell through the rotor support bearing, the planetary wheel support shaft is fixedly connected to the rotor and the two planetary carriers fixedly connected to it, and the first planetary wheel, the second planetary wheel are sleeved on the planetary wheel support shaft Two planetary wheels, planetary wheel support bearings, planetary wheel connection spline sleeves, the first planetary wheel and the second planetary wheel are supported on the planetary wheel support shaft through the planetary wheel support bearing, and the first planetary wheel and the second planetary wheel are supported by the planetary wheel The spline sleeve is connected to form an integral body, the inner ring of the first sun gear is keyed to the main shaft, and the outer teeth mesh with the first planetary gear to form the power input assembly of the first planetary gear; the inner ring of the second sun gear ...

Embodiment 3

[0038] see attached Figure 6 , attached Figure 12 The right side of the rotor is supported on the stator fixed frame through the rotor support bearing, and the left side is supported on the left hub shell through the small reduction ratio output one-way overrunning clutch. The planetary wheel support shaft is connected, and the planetary wheel support shaft is covered with the first planetary wheel, the second planetary wheel, the planetary wheel support bearing, the planetary wheel connection spline sleeve, the first planetary wheel and the second planetary wheel through the planetary wheel support bearing Supported on the support shaft of the planetary wheel, the first planetary wheel and the second planetary wheel are keyed together through the planetary wheel connection spline sleeve, the inner ring of the first sun wheel is keyed to the main shaft, and the outer teeth mesh with the first planetary wheel , the inner ring of the second sun gear is keyed to one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com