Traction converter for low-floor vehicle

A vehicle traction and inverter technology, which is applied to the output power conversion device, electrical components and other directions, can solve the problems of insufficient installation space on the roof, and achieve the effect of solving the lack of installation space, strong rainproof function, and meeting the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

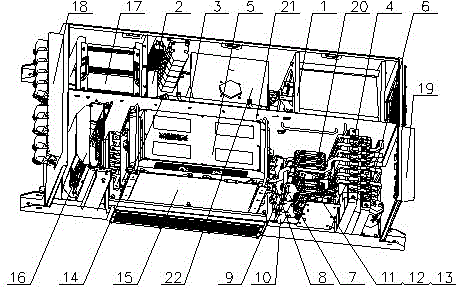

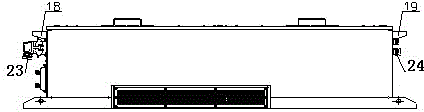

[0015] like figure 1 As shown, an embodiment of the present invention includes a cabinet, and the cabinet is divided into front and rear parts by a middle partition 21, wherein a transmission control unit 16, a converter module 5, and five current sensors are installed on the front of the cabinet. 6, 7, 8, 9, 10 and three voltage sensors 11, 12, 13, charging resistor 3, charging contactor, the installation position of the output contactor 20 is provided at the front of the cabinet; There is a CCU case 17, a fan 22, and a short-circuit contactor 4, and a line reactor 1 is installed at the rear of the cabinet on the outlet side of the fan 22.

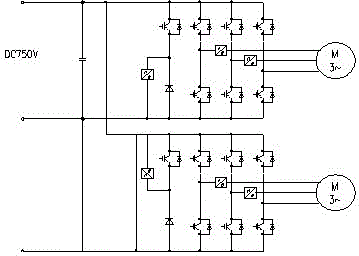

[0016] Under the traction working condition, the DC750V direct current after the high-voltage electrical box is connected to the traction converter cabinet, and enters the converter module 5 after passing through the line reactor 1, the charging contactor 2, the charging resistor 3, and the short-circuit contactor 4. The current converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com