Method for making press-in-place gaskets

A technology of gasket components and sample pads, which is applied in the field of press-in-place gasket manufacturing, can solve problems such as modification or discarding, and parts that cannot be matched accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

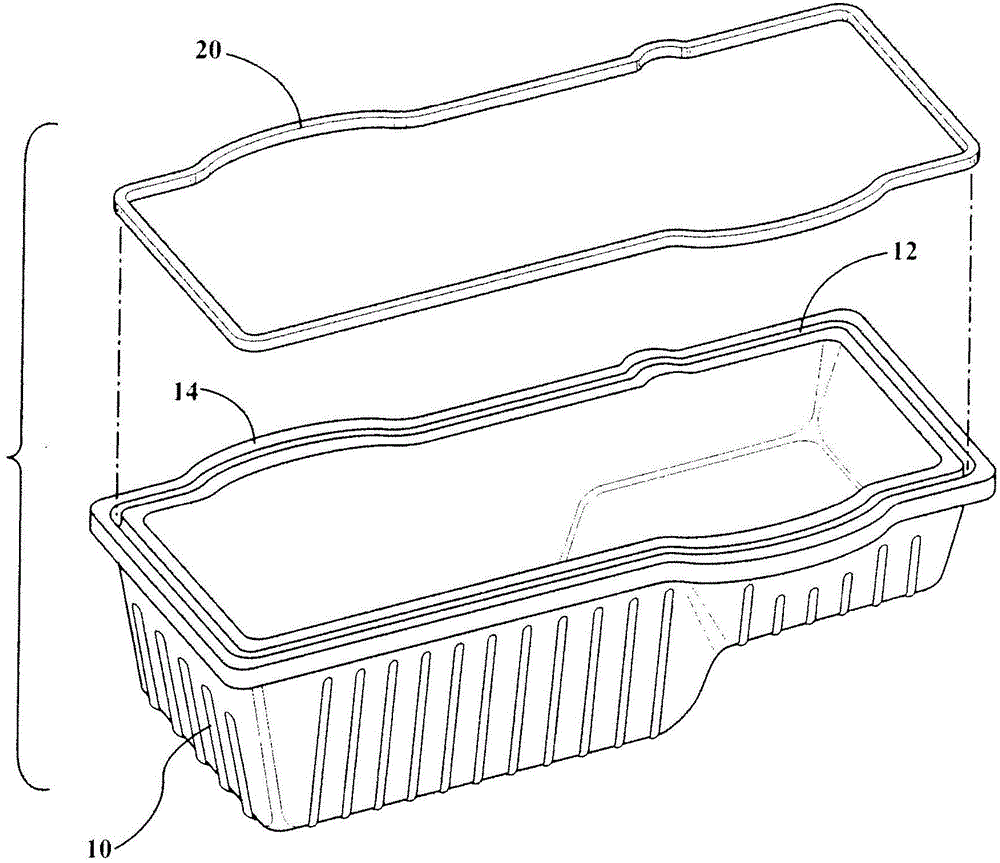

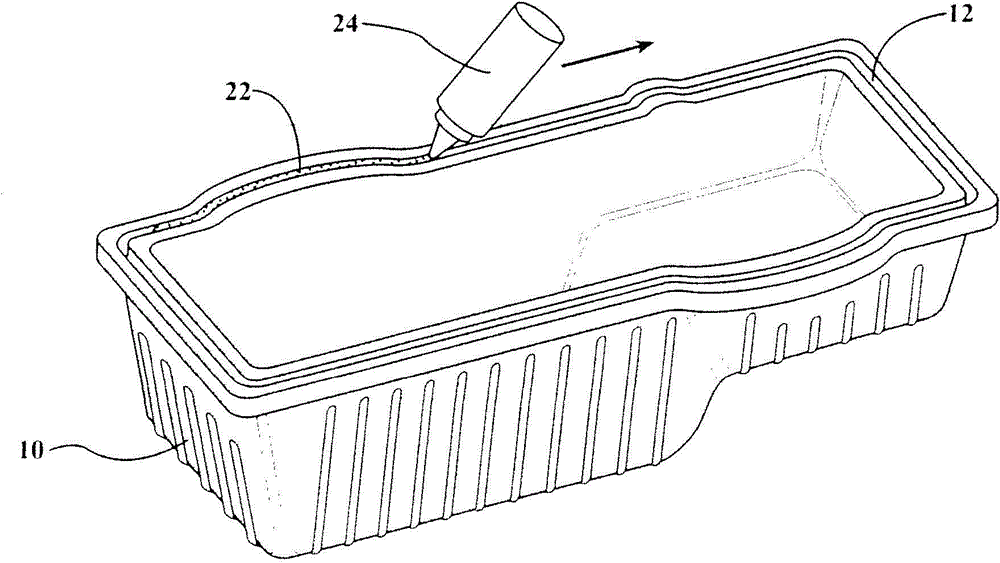

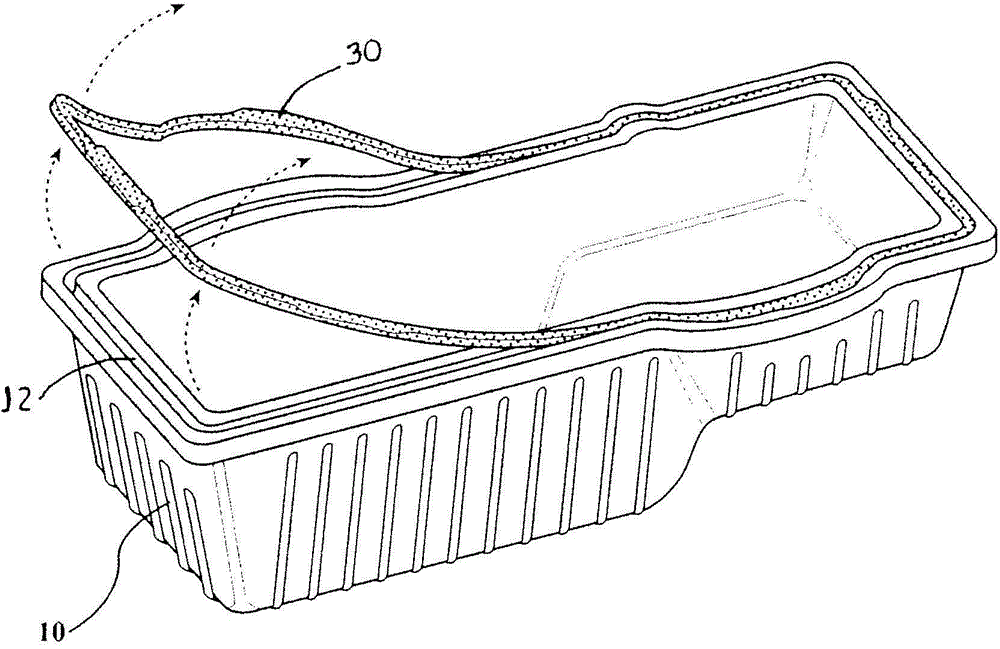

[0019] The manufacturing process of the present invention is shown in Figures 1-6. Figure 7 is a flowchart of an exemplary embodiment. This process is used to produce press-in-place (PIP) gasket components in a more precise and faster manner. A rigid sample of the shim is made by the process of the present invention, the rigid sample being the same size and shape as the original shim included in the original part.

[0020] Problems can arise if the sample replacement gasket is not laid out and manufactured exactly like the original gasket received in the groove of the engine component. In this regard, PIP gaskets are used in different engine and vehicle components such as oil pans and valve covers. Other products that commonly use PIP gaskets include water pumps, intake manifolds, etc.

[0021] To illustrate the invention in detail, the process will be described in conjunction with an oil pan cover. It should be understood, however, that the process of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com