A high-precision die-casting mold with a local pressurization mechanism and its casting method

A die-casting mold, local pressurization technology, applied in the field of die-casting molds, to reduce or eliminate shrinkage defects, reduce porosity and shrinkage defects, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

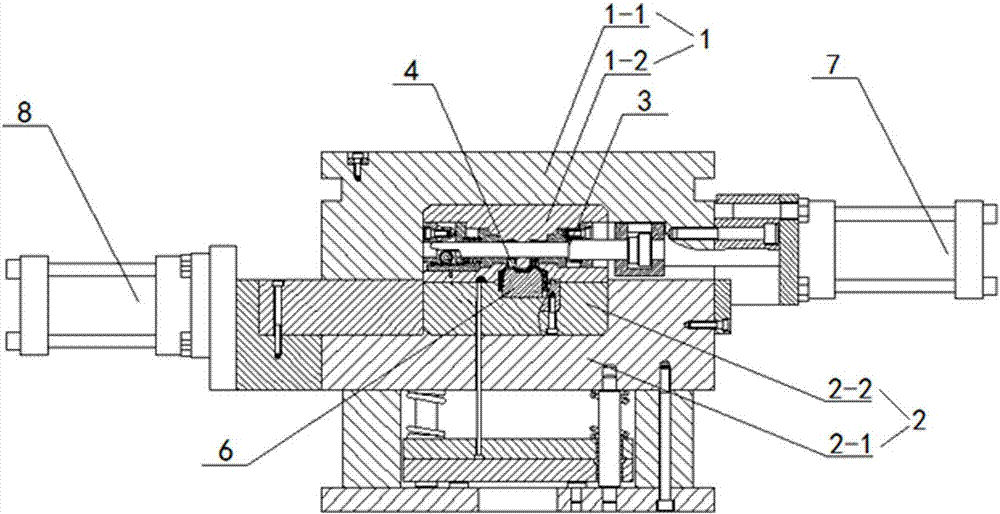

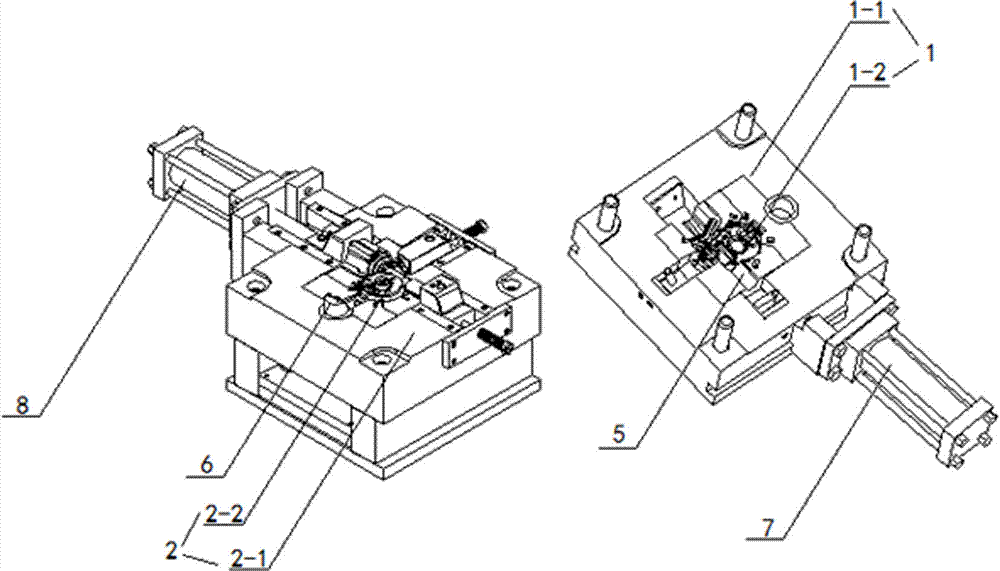

[0031] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with reference to the embodiments and accompanying drawings.

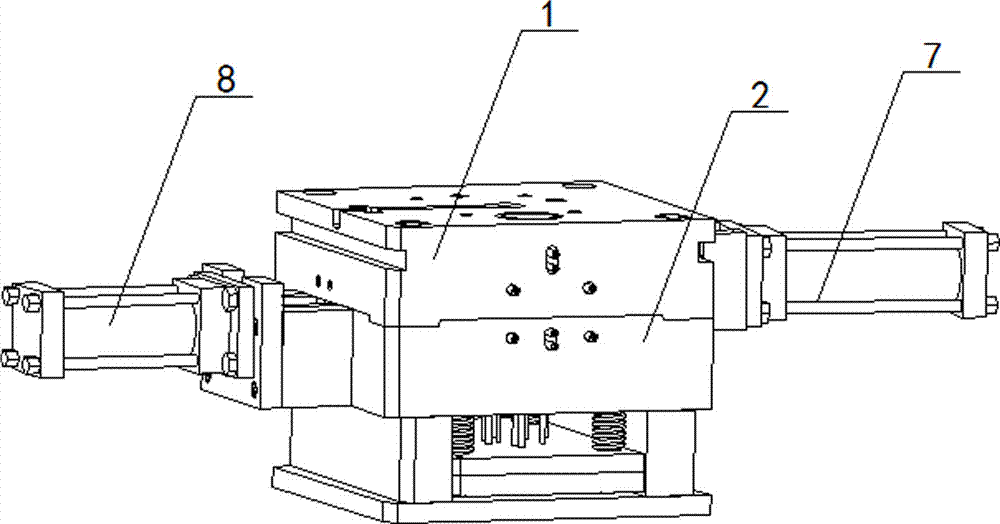

[0032] refer to Figure 1-5 , a high-precision die-casting mold provided with a local booster mechanism, comprising an upper mold 1, a lower mold 2 and a booster mechanism 3, the booster mechanism 3 is arranged on the upper mold 1, and the upper mold 1 and the lower mold 2 are provided with a workpiece cavity 4, and the upper mold 1 is provided with an installation cavity 5 for installing a booster mechanism 3, and the installation cavity 5 passes through the workpiece cavity 4; the booster mechanism 3 includes a The gear 3-1, rack 3-2, booster rod 3-3 in the installation cavity 5 and the left booster block 3-4 and the right booster block 3-5 that can move inward relative to the workpiece cavity 4 at the same time, so One end of the booster rod 3-3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com