A composite machining method of electric spark discharge ablation and electrolysis of atomized medium with adjustable conductivity

An atomizing medium and compound machining technology, applied in the field of EDM, can solve the problems of low machining efficiency, singleness, low energy input, etc., and achieve the effects of low relative loss, cost reduction, and accelerated erosion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following structural drawings and embodiments further illustrate the present invention.

[0028] Such as figure 1 -2 shown.

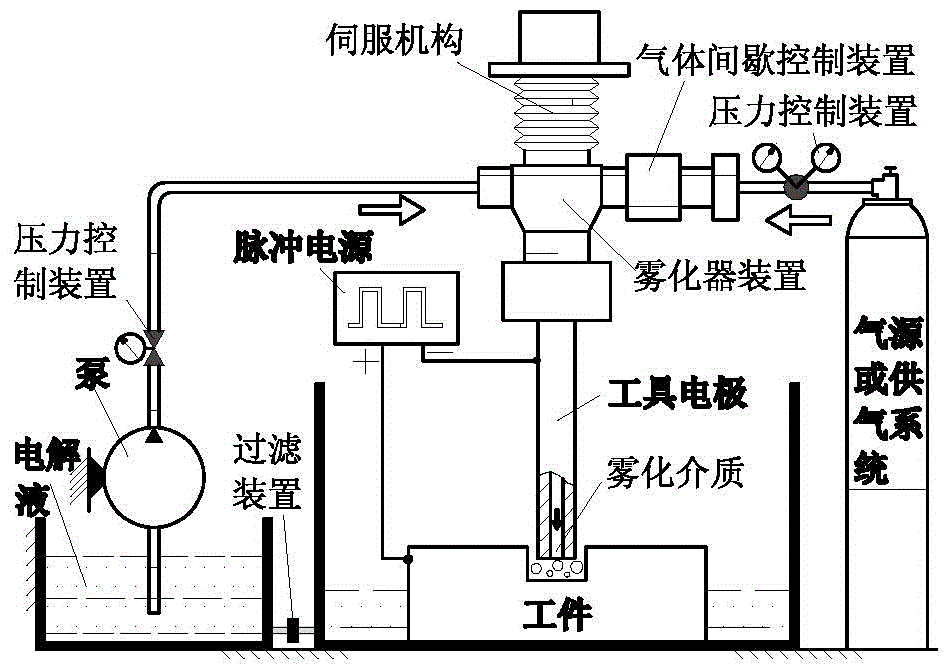

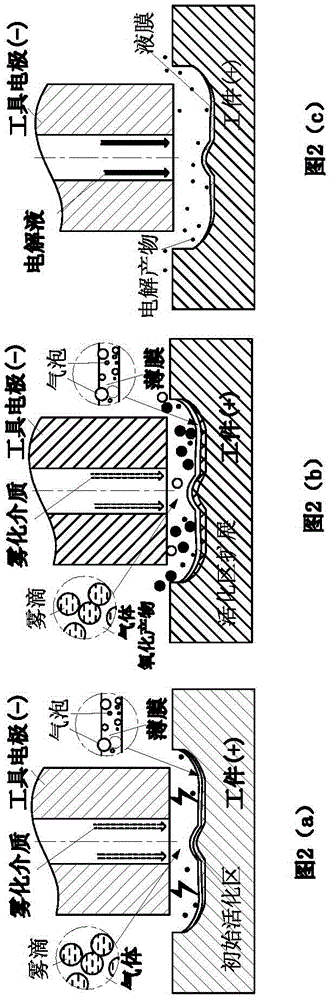

[0029] An atomized medium electric spark discharge ablation and electrolysis composite processing method with adjustable conductivity, the processing device used is such as figure 1 As shown in Figure 2, a typical processing process is shown in Figure 2. The essence is that in the process of EDM-induced ablation, the electrolyte is used to replace the insulating working medium used in EDM, and it is compatible with the flammable (supporting) flammability Gas (such as oxygen) forms an atomized medium and is sprayed into the processing area. During the processing, the ratio of gas to electrolyte is adjusted to control the conductivity of the atomized medium, so as to achieve the following in different stages of the entire processing process according to processing requirements or stages. Discharge-induced ablation as the main method, or disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com