A support system for subway foundation pit and its construction method

A technology for supporting systems and subways, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as low construction efficiency, large safety hazards, and limited working space, and achieve low-carbon environmental protection, stability and safety assurance, and large machinery. The effect of work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

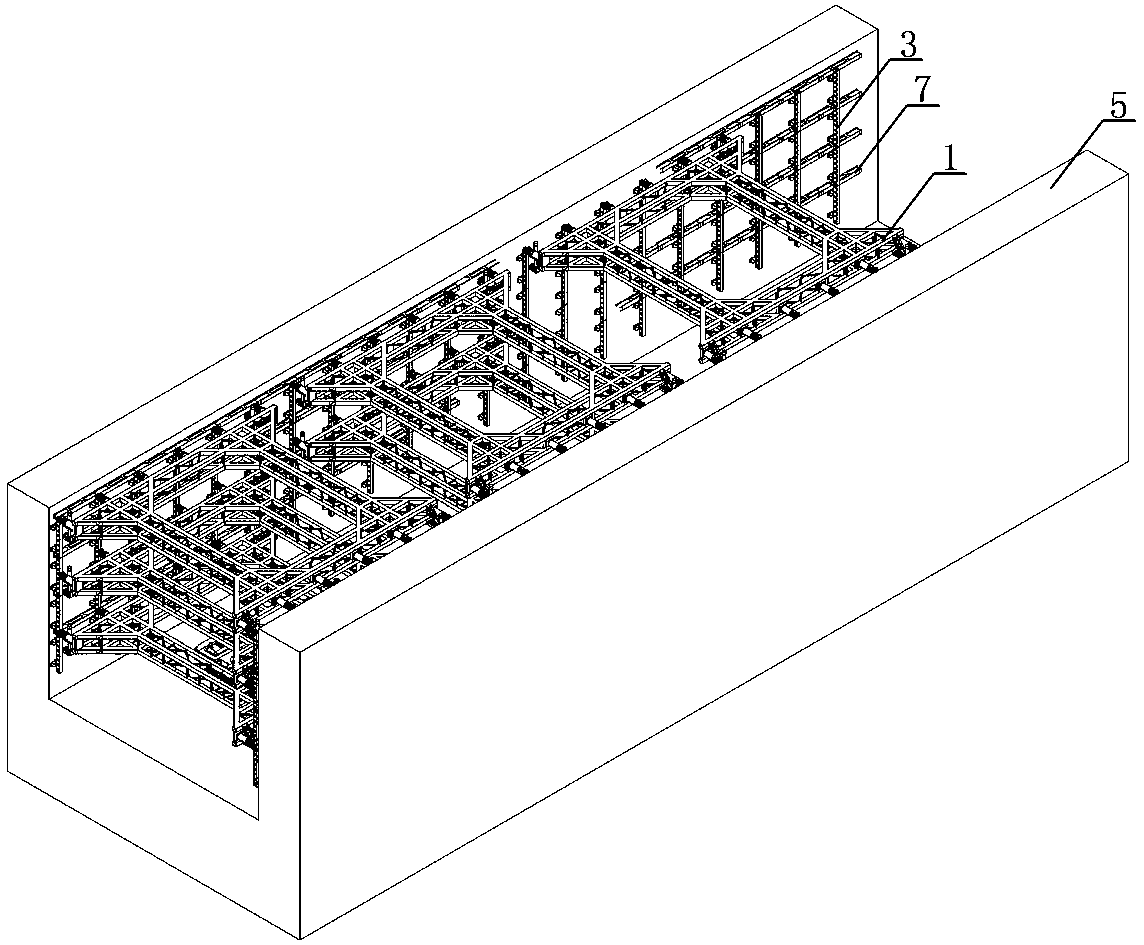

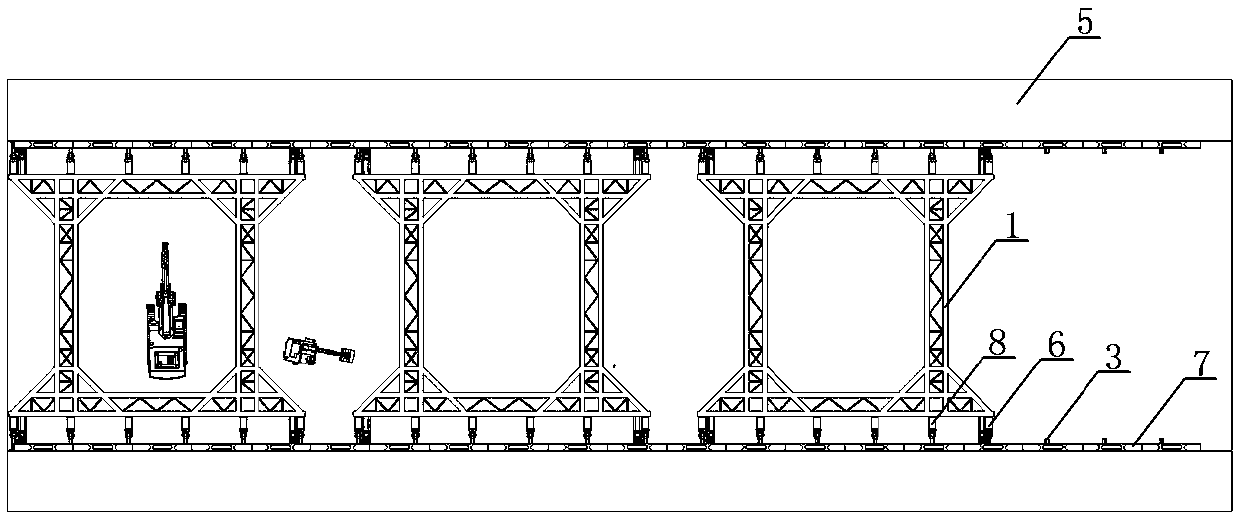

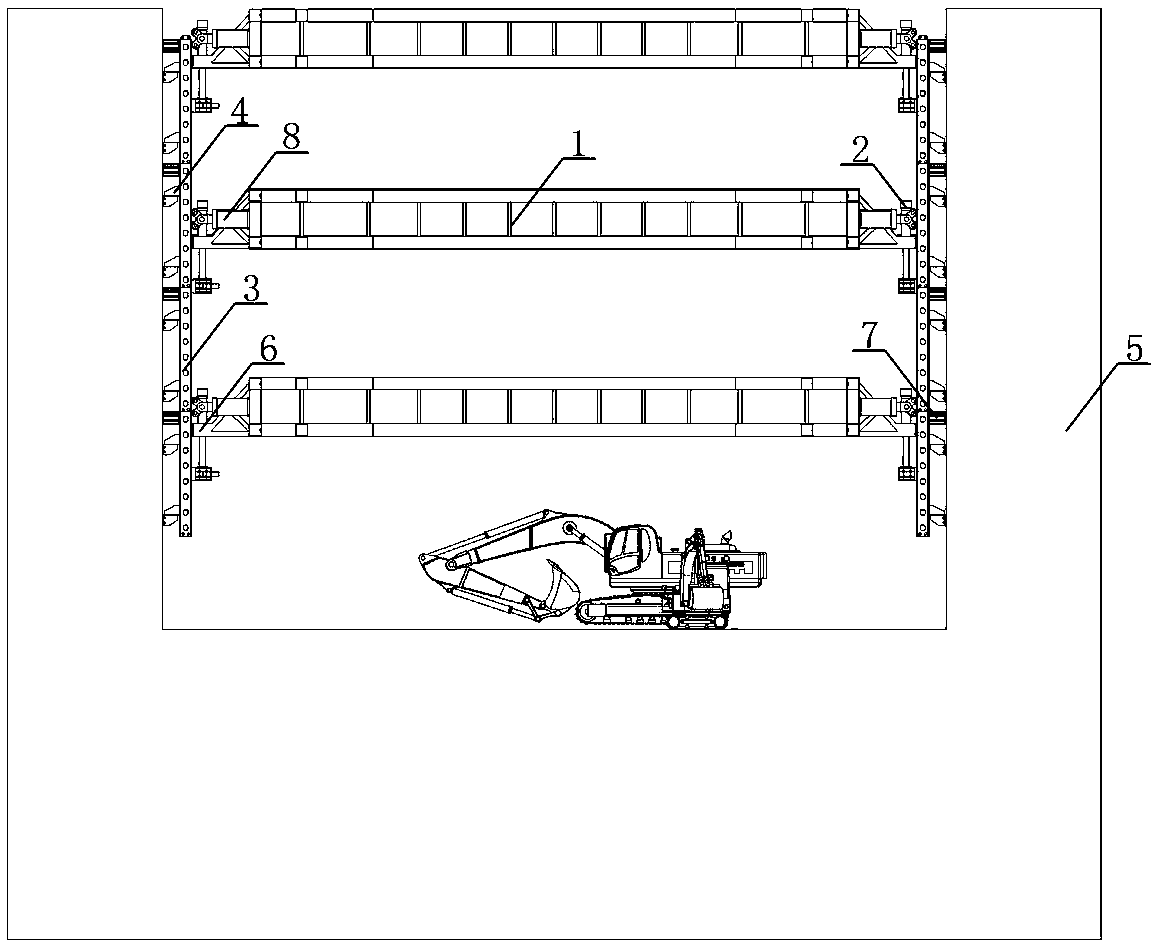

[0045] Examples see figure 1 , figure 2 , image 3 As shown, this support system for subway foundation pits includes horizontal support platforms that are horizontally supported between foundation pit enclosure structures 5, and the horizontal support platforms 1 are evenly distributed at parallel intervals along the length and height directions of the foundation pit , is characterized in that: it also includes a guide rail 3, a lifting power unit 2 and a force transmission mechanism 8; the guide rail 3 is arranged in parallel and at intervals along the length direction of the foundation pit enclosure structure 5; the lifting power unit 2 is connected to the horizontal support platform 1 Between the guide rail 3; the force transmission mechanism 8 is connected between the horizontal support platform 1 and the guide rail 3; the guide rail unit 3.1 is connected with the foundation pit enclosure structure 5 through the adjustable support assembly 4, and the unit bracket 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com