Cavity tunnel type inflation-free damping tire

A shock-absorbing tire and tunnel-type technology, used in non-pneumatic tires, tire parts, transportation and packaging, etc., can solve problems such as poor heat dissipation, poor shock absorption, and bulkiness, and achieve good shock absorption and easy disassembly. The effect of installing tires and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

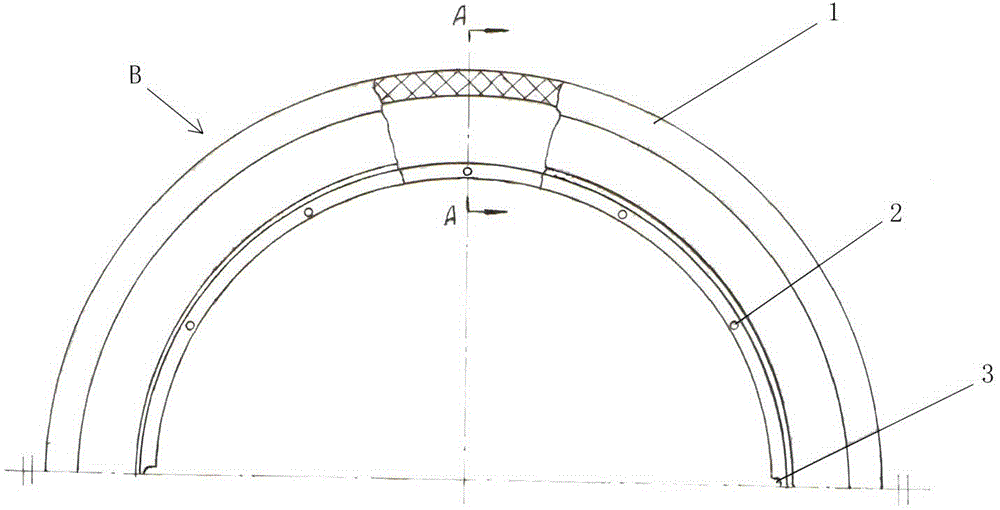

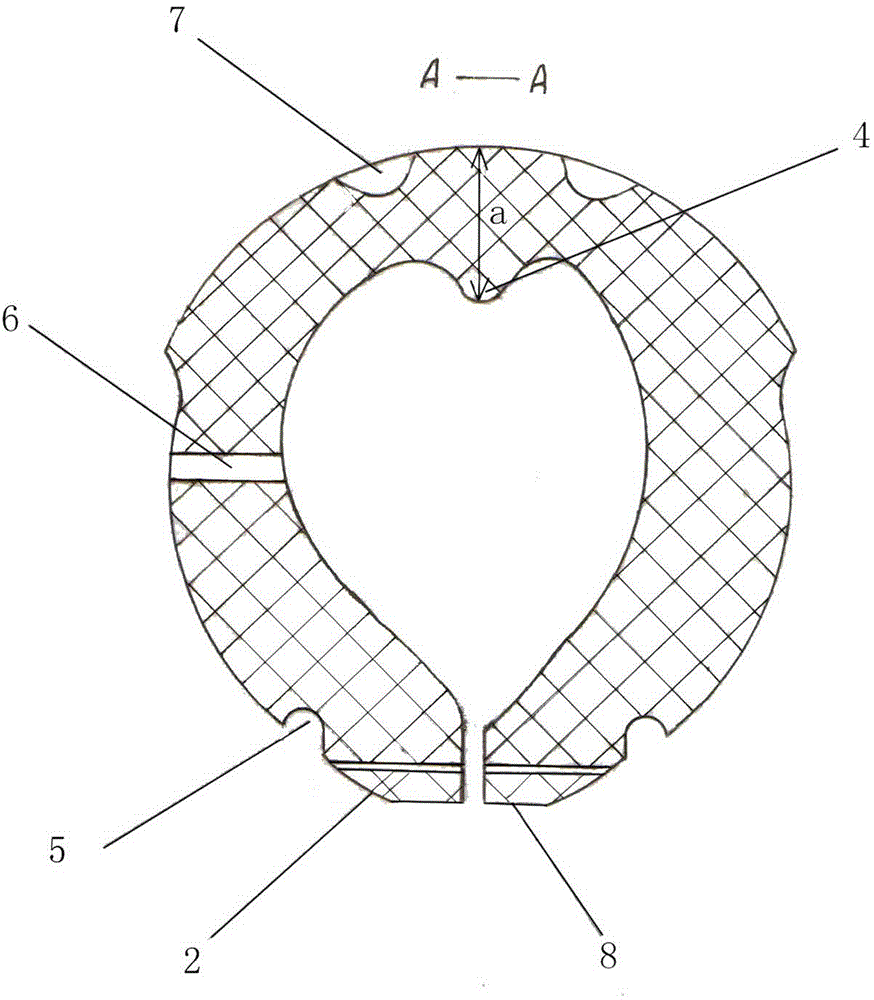

[0026] Depend on Figure 1-3 From the shown embodiment, it can be known that it includes a carcass 1, tire patterns located on the carcass 1 and supporting slots 5 matching the rim edge; It is in the shape of a corrugated plate, and the crest of the corrugated plate on one side of the inner wall corresponds to the trough of the corrugated plate on the other side of the inner wall, and a circular rib is provided at the center of the crown top of the inner wall of the carcass 1 4. The shape of the cross-section of the support slot 5 is a semi-circular arc.

[0027] A tire opening plane 8 is provided at the tire opening of the carcass 1 .

[0028] Vents 2 are arranged below the holder slot 5, and there are more than two vents 2 distributed uniformly.

[0029] The distance a from the apex of the outer edge of the carcass 1 to the apex of the annular rib 4 is more than twice that of a conventional tire of the same size.

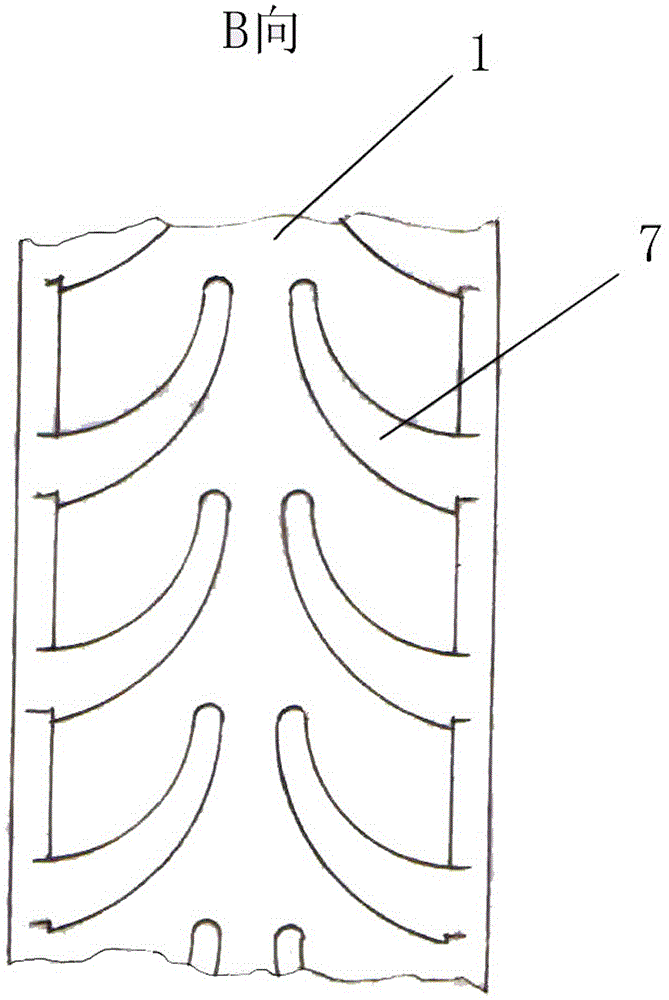

[0030] The tread pattern is a splayed pattern 7 located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com