Power transmission device for omni-directional mobile platform

A technology of power transmission device and all-round movement, which is applied in the direction of control devices, transportation and packaging, vehicle parts, etc., can solve the problems of the omni-directional mobile platform not being able to drive normally, and achieve the advantages of convenient assembly, ensuring the strength of cooperation, and ensuring the strength of connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

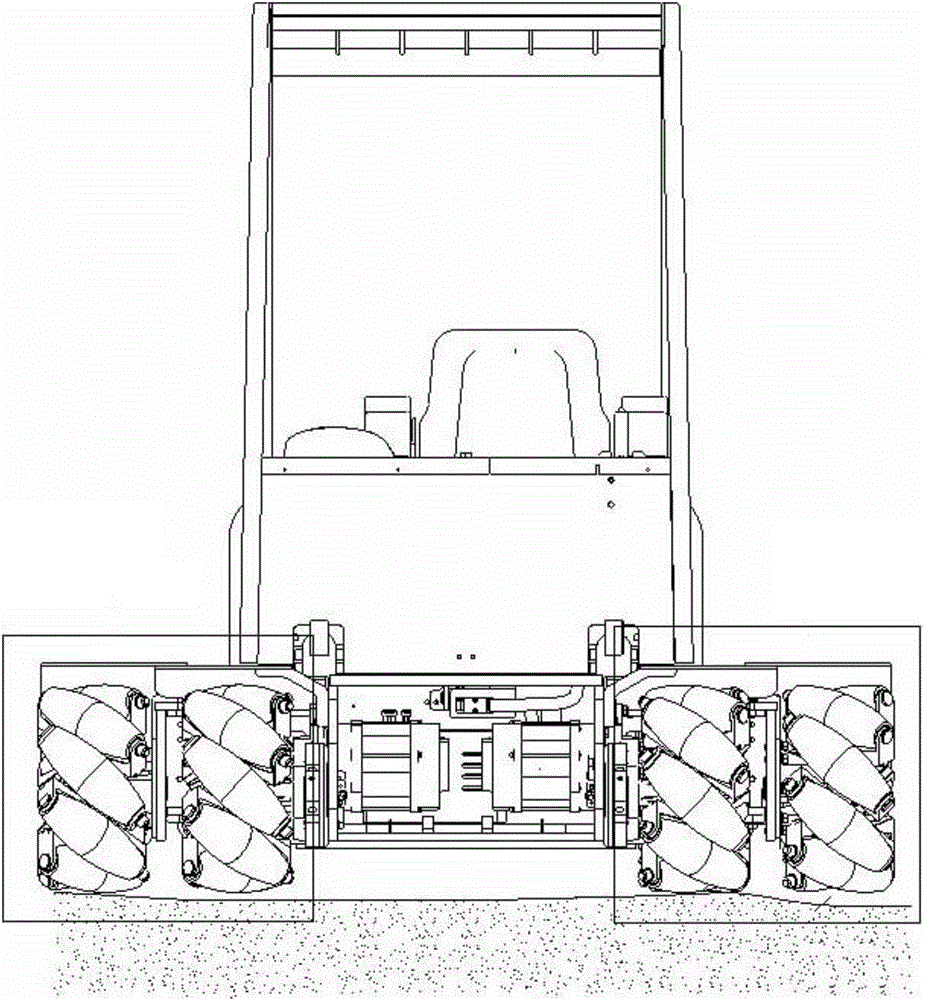

[0020] This embodiment provides a power transmission device for an omnidirectional mobile platform, which can be used in the arrangement structure of the front double wheels and the front double wheels of the omnidirectional mobile platform.

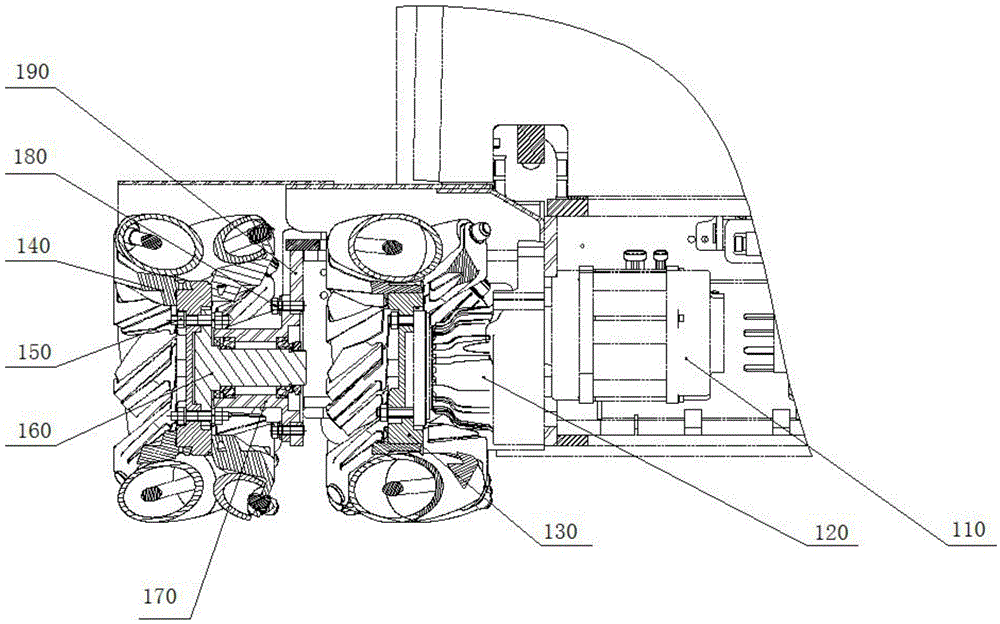

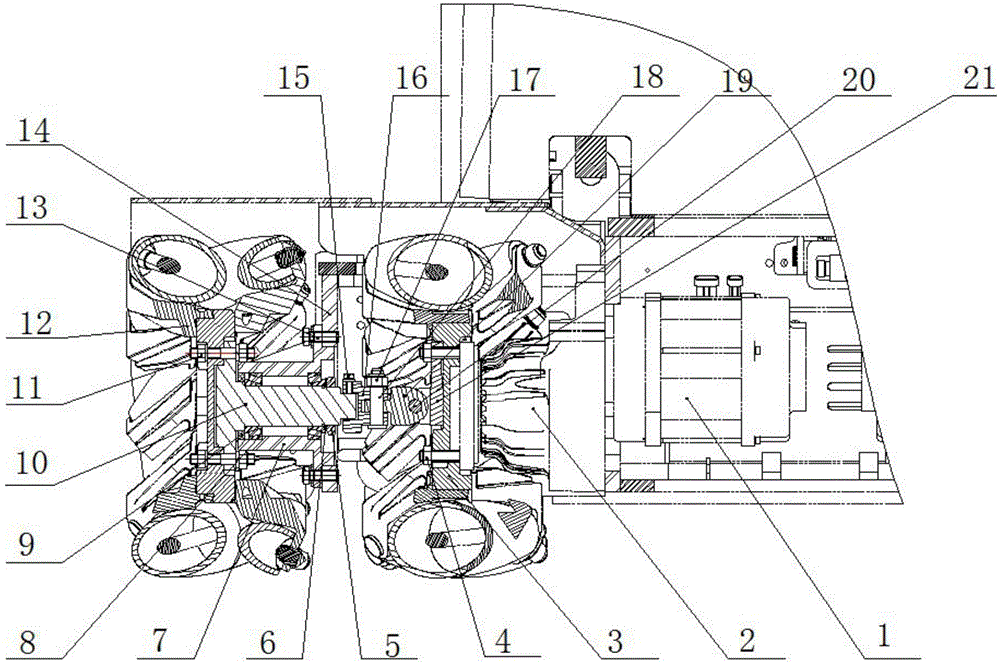

[0021] Such as image 3 As shown, a power transmission device for an omnidirectional mobile platform in this embodiment includes an inner omnidirectional wheel 3 and an outer omnidirectional wheel 12 . Wherein, the power of the inner omni-directional wheel 3 is input by the power source 1 through the gearbox 2, and the inner omni-directional wheel 3 is provided with a support seat 21 through the connecting bolt 4, and the support seat 21 is rotatably connected with a connecting shaft 19. The outer omnidirectional wheel 12 includes a hub 10 configured to be rotatably connected to the support frame 7 fixed on the vehicle frame 14 . The two ends of the connecting shaft 19 are respectively constructed with a shaft hole whose axes are orthog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com