Method for installing or removing high voltage bushing by using C-shaped hoseclamp cross binding strap

A technology of high-voltage bushings and slings, which is applied in the direction of transportation, packaging, and load-hanging components. It can solve problems such as damage to equipment, low work efficiency, and dilemmas, and achieve efficient installation or removal, high-efficiency and safe work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

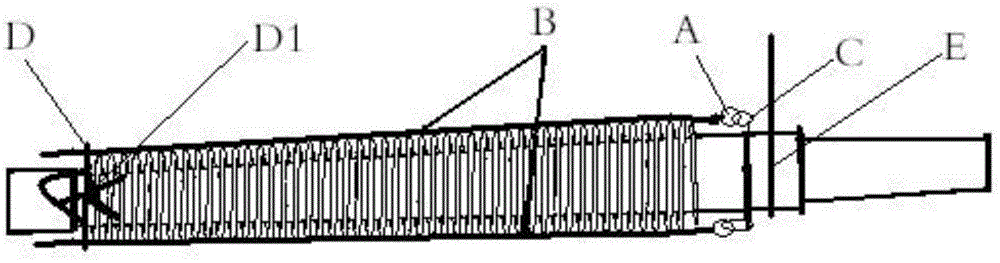

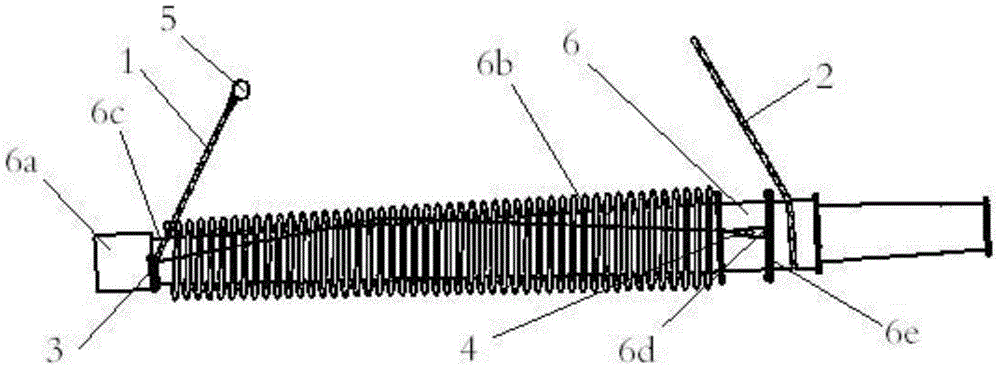

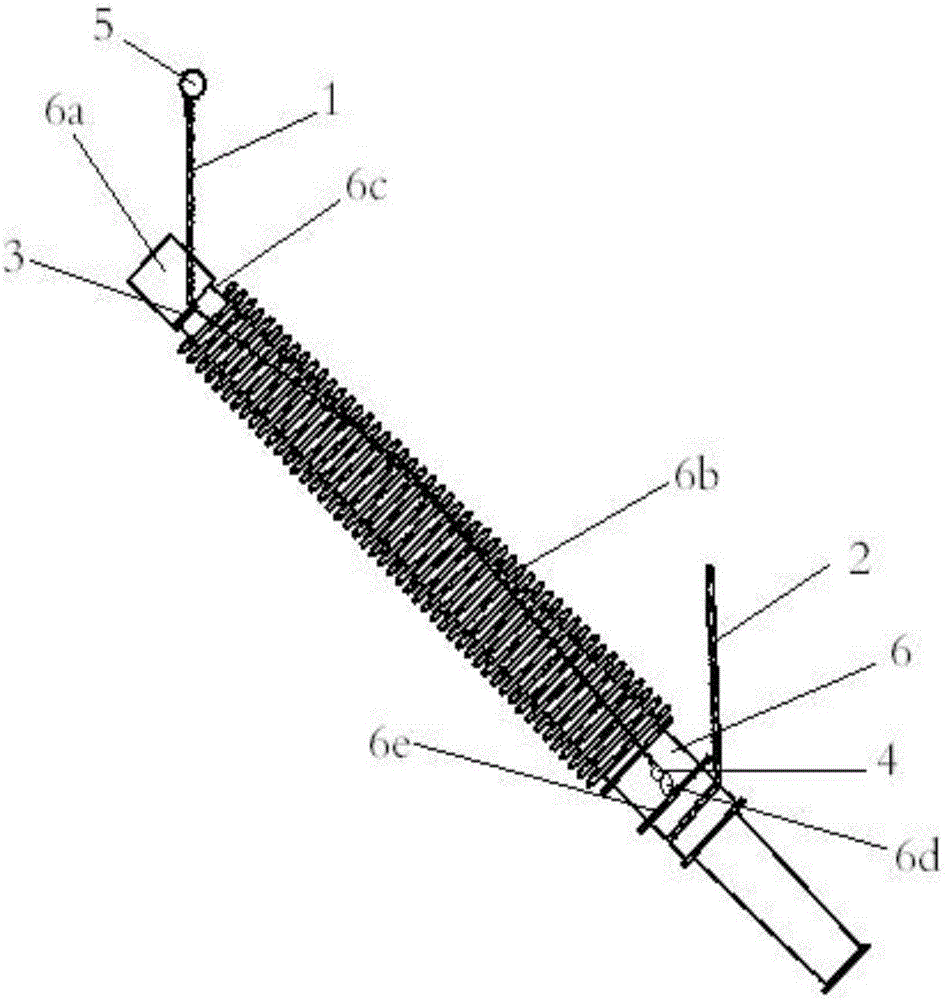

[0031] Such as diagram 2-1 , Figure 2-2 , Figure 2-3 As shown, the C-shaped throat hoop cross-bundling sling used in the method of the present invention includes two equal-length main slings 1, an annular auxiliary sling 2, a throat hoop sling 3 that can be bent into a C shape, and two main slings 1 The two ends of the tool U-shaped ring 4 and special lifting ring 5 are respectively equipped with; the throat hoop sling 3 consists of a image 3 The closed loop shown is folded in half and twisted to form a bend such as Figure 4 the shape shown. The main sling 1, the annular auxiliary sling 2, and the throat hoop sling 3 are all nylon slings. The invention adopts C-shaped throat hoops to cross-bundle suspenders to install or remove high-voltage bushings.

[0032] The operation method of installing the high voltage bushing is as follows:

[0033] a. Measure the outer circumference of the upper oil chamber of the high-voltage casing, and obtain the 1 / 2 circumference value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com