Suspension hanging basket for installation of roof surface bottom layer color plate

A color board and bottom layer technology, applied in the direction of scaffolding, house structure support, house structure support, etc., can solve the problems of affecting the completion of the project, insecure safety, and high cost, and improve the accuracy of positioning and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

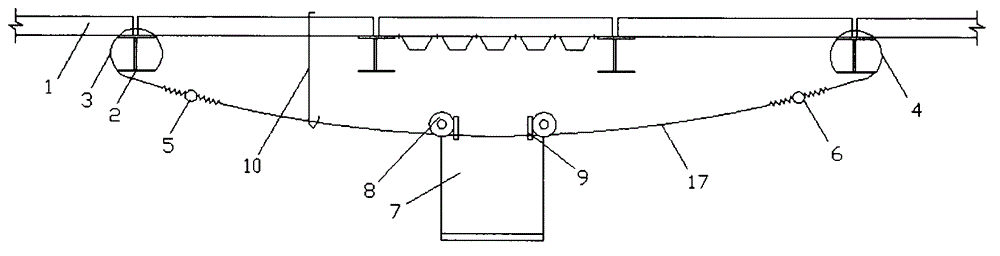

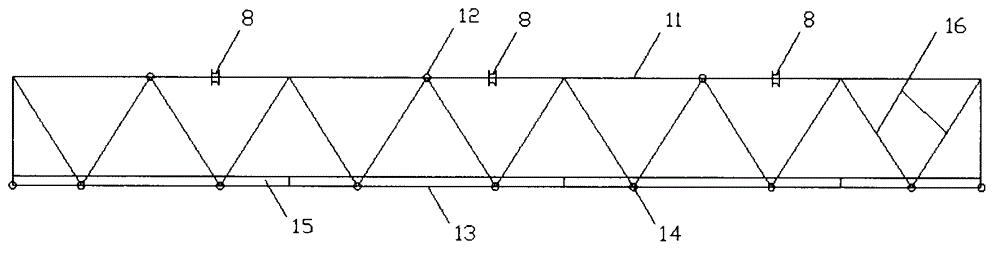

[0017] Example: such as figure 1 As shown, the present invention is a hanging basket for installing the color plate of the bottom layer of the roof. 3 and the second steel wire rope 4, the first steel wire rope 3 is connected to the third steel wire rope 17 through the first hand hoist 5, the second steel wire rope 4 is connected to the third steel wire rope 17 through the second hand hoist 6, and the third steel wire rope 17 is movably connected hanging basket 7 by pulley 8.

[0018] Further, adjustment hooks 10 are provided on the third wire ropes 17 on both sides of the hanging basket 7 . By adjusting the hook 10, the interference degree of the third wire rope 17 itself can be effectively reduced. The number of the third wire rope 17 and the pulley 8 is 3-5, and a self-clamping device 9 is provided on one side of the pulley 8 . A plurality of pulleys 8 are installed on the hanging basket 7, and the third wire rope 17 is passed through the pulleys 8.

[0019] The hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com