Glass bottle combined inspection gauge of bottle making machine production anti-fake bottle mouths

A technology for inspecting gauges and glass bottles, applied in the field of bottle mouth inspection tools for glass bottles, can solve the problems of a large number of glass bottle inspections, the inability of glass bottles to enter in time, and the waste of production costs, so as to eliminate the phenomenon of missed inspection and avoid quality risks. , avoid the effects of manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

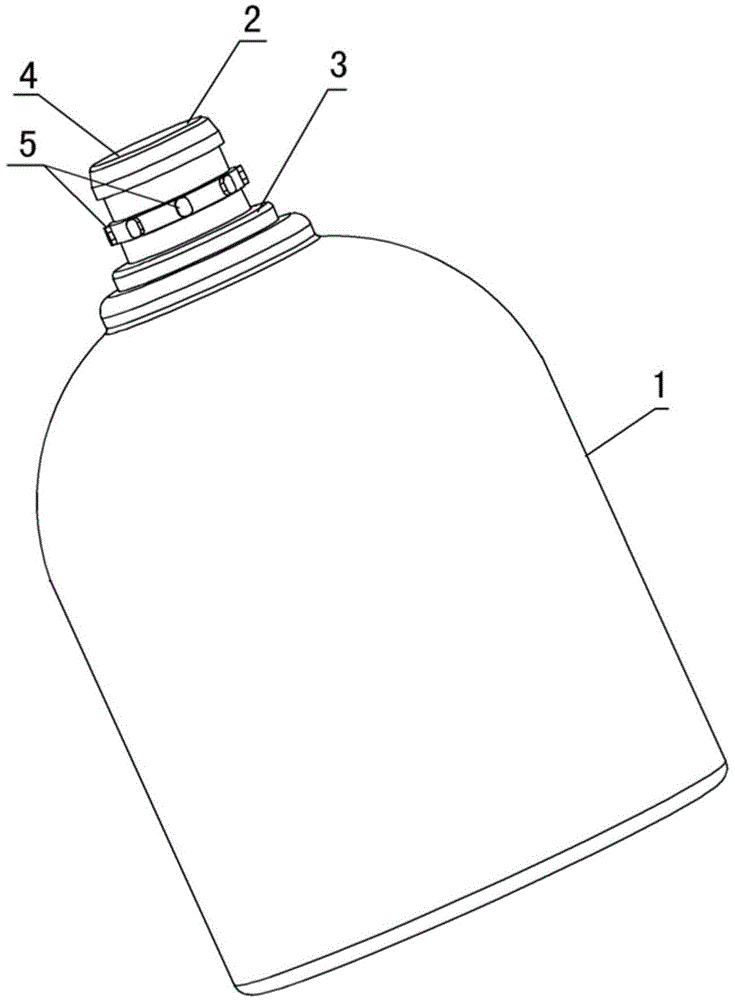

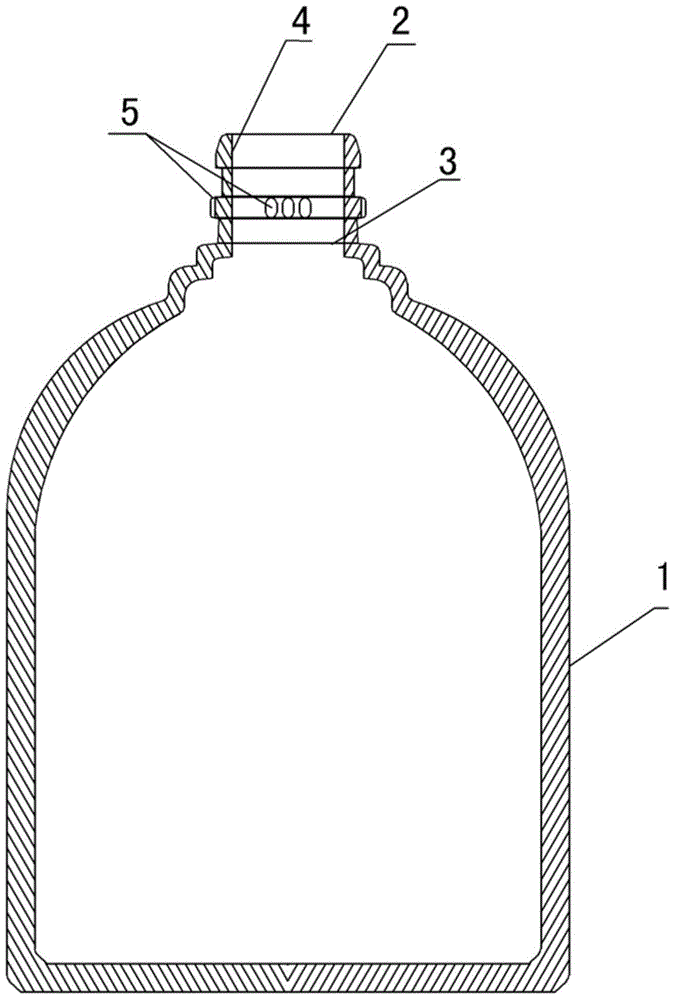

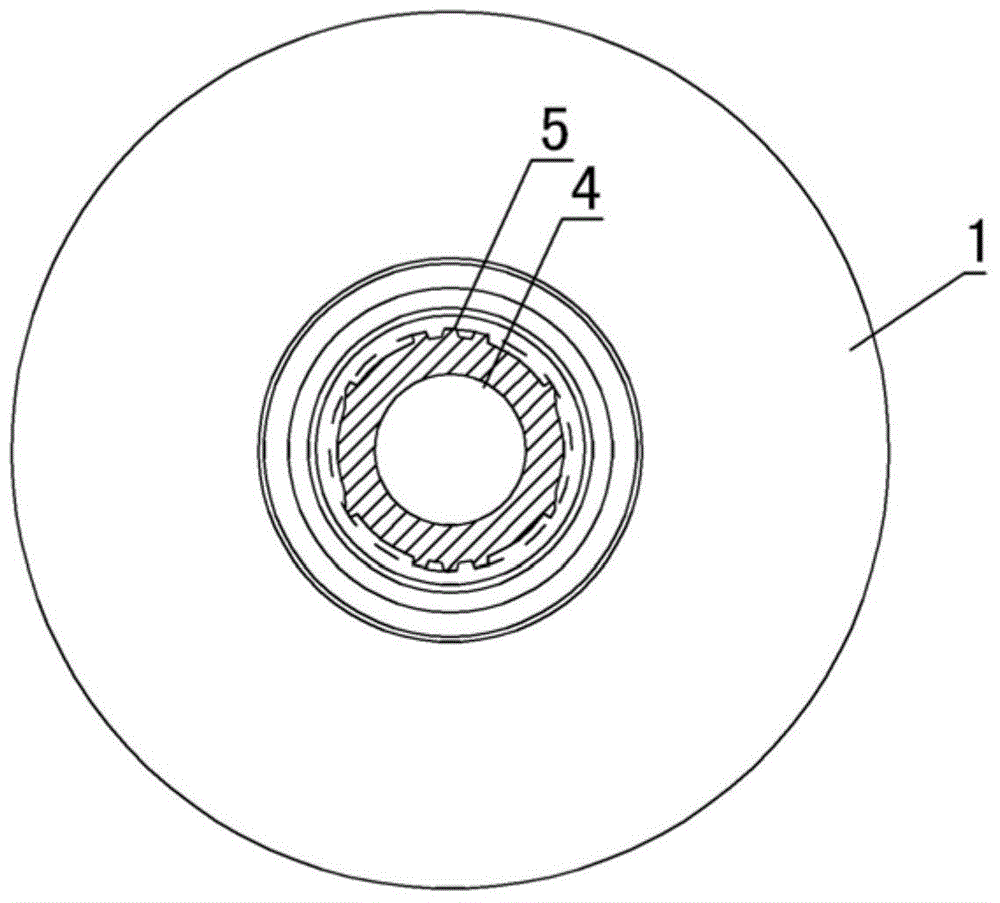

[0040] Such as figure 1 , Figure 1a with Figure 1b As shown, the bottle mouth anti-counterfeiting teeth 5 are arranged between the bottle mouth end face 2 and the bottle table end face 3 of the anti-counterfeiting bottle mouth of the glass bottle 1, in order to check the height between the bottle mouth end face 2 of the glass bottle 1 and the bottle table end face 3, the bottle The upper and lower limits of the diameter of mouth anti-counterfeit tooth 5, have designed a kind of as image 3 Shown test gauge 10; In order to check whether the bottle mouth inner wall 4 can be inserted as figure 2 The needle head 9 of shown liquor filling needle 6 has designed a kind of as Figure 4 The inspection plug gauge 15 shown;

[0041] Such as image 3 , Figure 3a with Figure 3b As shown, the interior of the test gauge 10 is provided with a cylindrical "convex" cavity, and the upper cavity of the cylindrical "convex" cavity is a connecting part of the internal thread structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com