Method for aligning rotation position of at least two components and positionging device

A technology of rotating position and positioning device, which is applied in the direction of positioning device, metal processing machinery parts, manufacturing tools, etc., can solve the problems of increasing production cost, high technology, time consumption, etc., and achieve simple implementation, less structural space, and accelerated assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

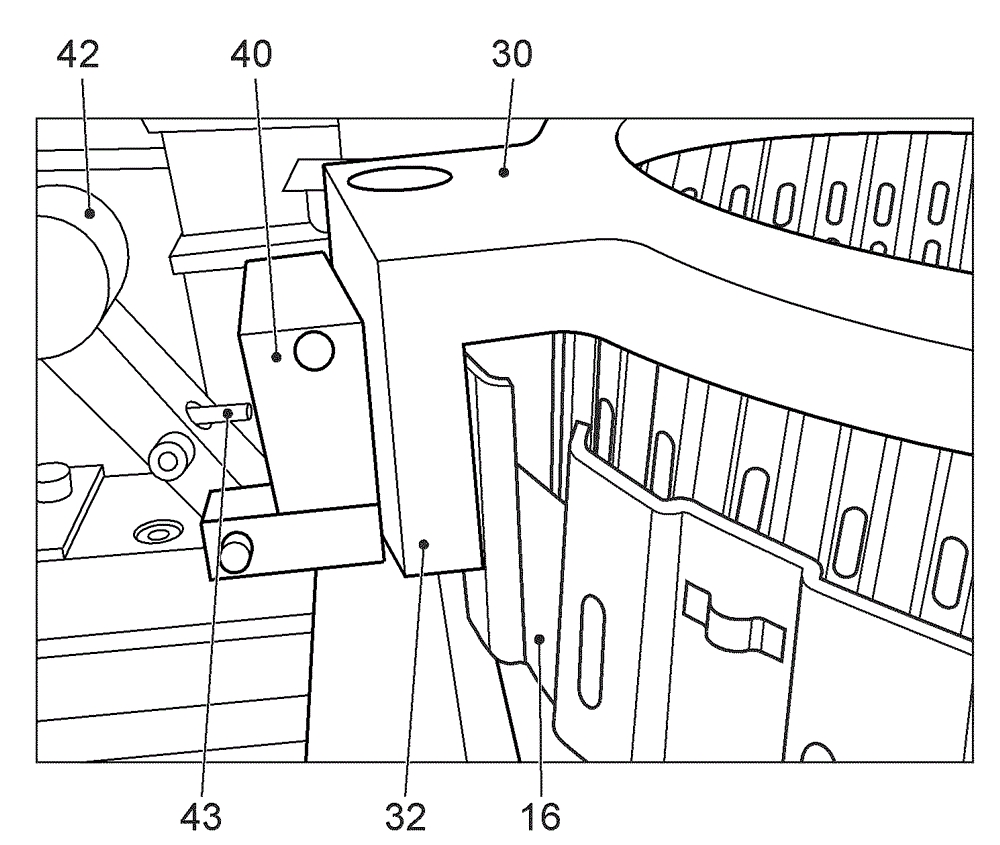

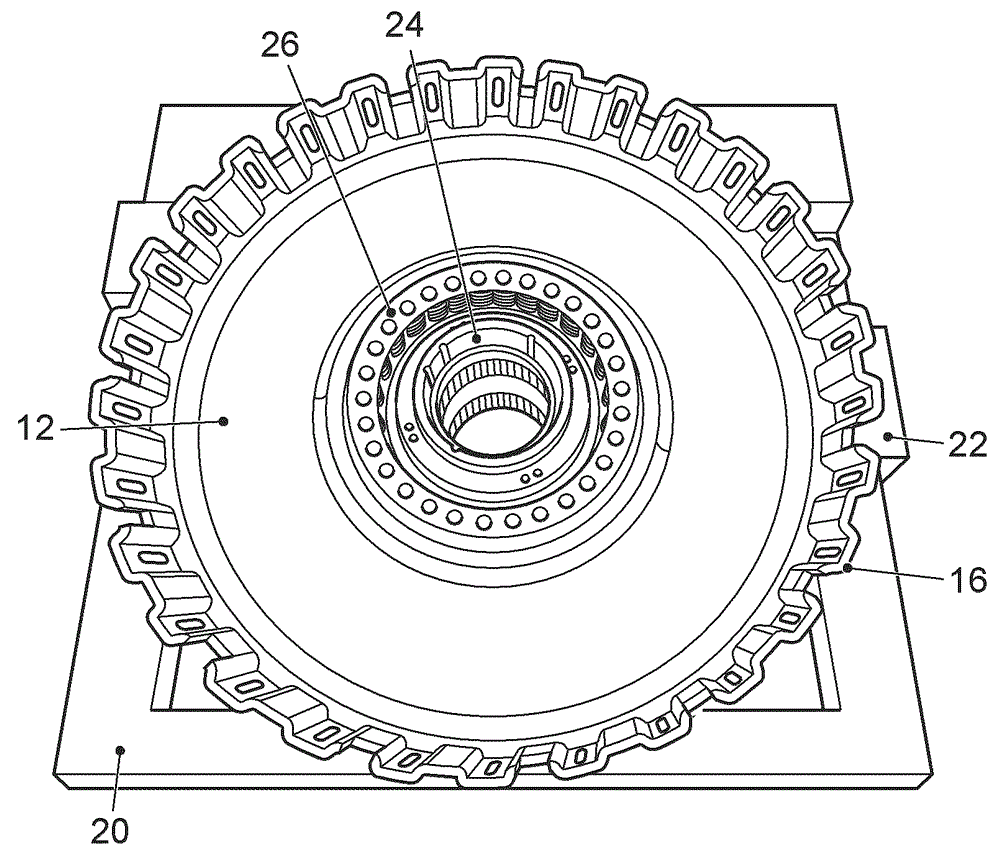

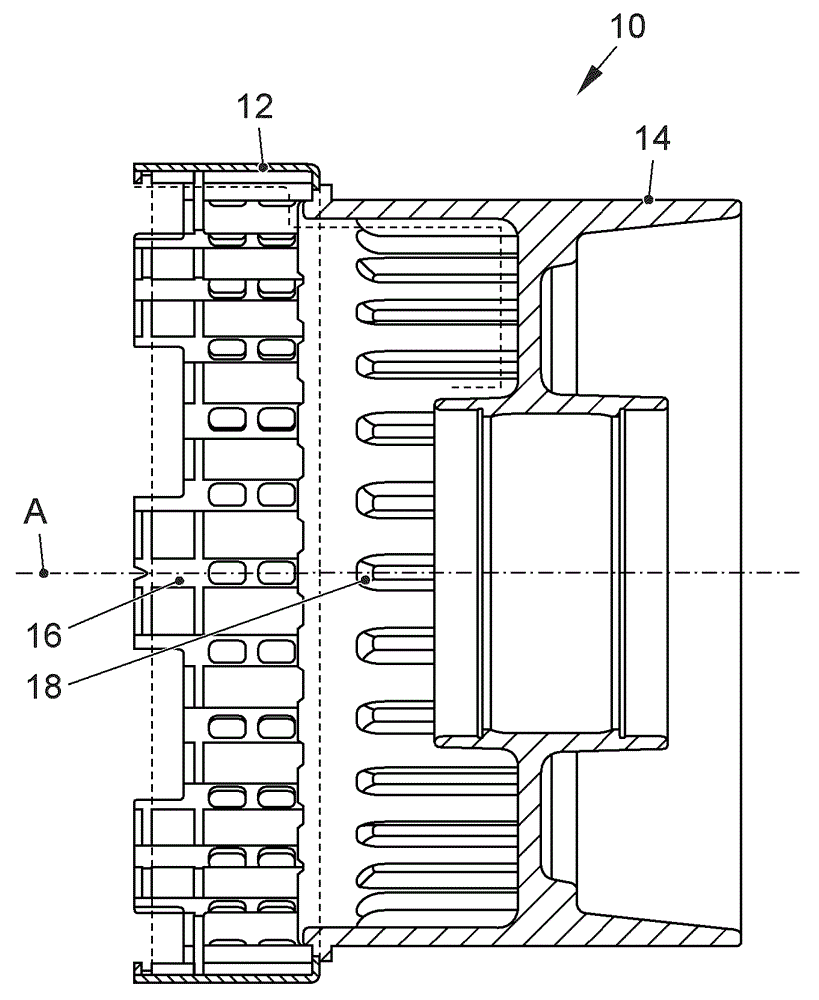

[0055] figure 1 The side view shows a component group 10 which is, for example, a component of a dual clutch transmission. The component group 10 rotates about a common axis A. The component group 10 has a first component 12 and a second component 14 . The two components are rotationally symmetrical with respect to the axis A. Components 12 , 14 are, for example, outer platters of a dual clutch transmission, which rotate about axis A at the rotational speed of the internal combustion engine and transmit the rotational speed to an inner platter (not shown).

[0056]The first component 12 has a first notch 16 or a first toothing with notches, while the second component 14 has a second toothing 18 or a second toothing with notches.

[0057] as in figure 2 As shown in , the toothing 16 , 18 is embodied as peripheral toothing. The toothings 16 , 18 are not designed here as meshing transmission toothings, but serve as carriers for the discs of the clutch. In order to simplify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com