Ink-sucking pipe equipped with stopper device for ink cartridge

A limit device and ink suction tube technology, which is applied in the field of ink suction tubes, can solve problems such as nozzle blockage or damage, poor image quality, and print nozzle damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will now be described in conjunction with the accompanying drawings.

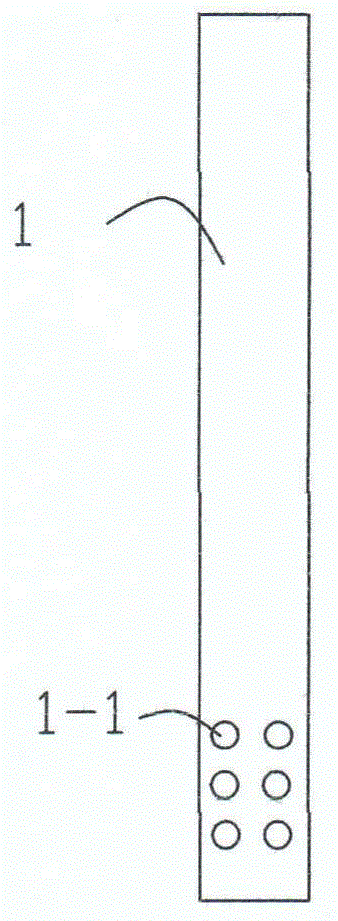

[0014] figure 1 It is a schematic diagram of the first preferred embodiment of the ink suction tube of the present invention. Such as figure 1 As shown, one end of the ink suction tube 1 is provided with a limiting mechanism 1-1.

[0015] Such as figure 1 As shown, the position-limiting mechanism is made up of several small holes 1-1. In this way, when the ink level drops to be flush with the uppermost aperture 1-1, the pressure inside and outside the ink suction tube reaches a balance, and the ink suction tube 1 can no longer suck ink, thereby ensuring that the ink will not be sucked dry.

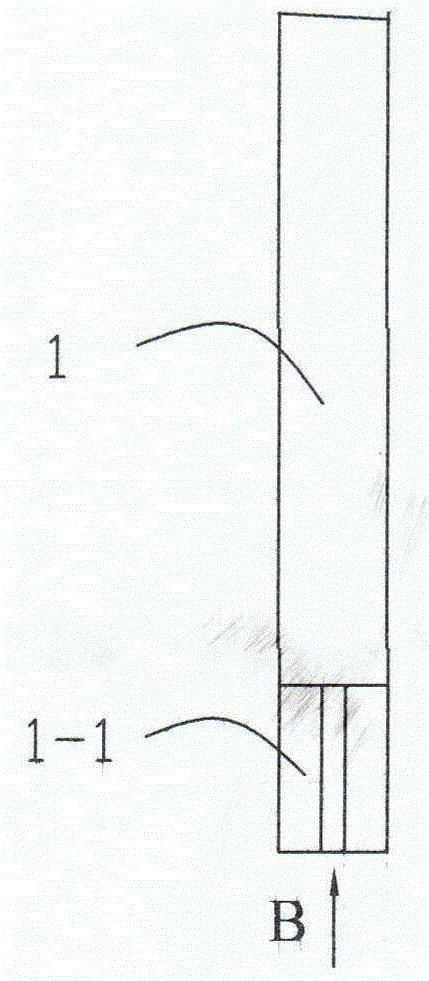

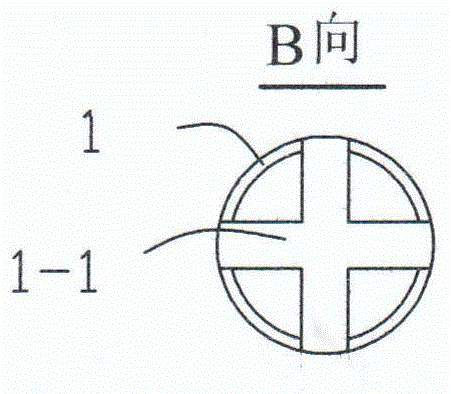

[0016] figure 2 and image 3 It is a schematic diagram of the third preferred embodiment of the ink suction tube of the present invention. This embodiment provides another structure of the limiting mechanism. Such as figure 2 and image 3 Shown, the position-limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com