Alcohol-soluble ink for white board marker

A pen-ink and whiteboard technology, applied in the field of ink, can solve problems such as bad smell, strong smell of alcohol-soluble ink, difficult to erase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The preparation method of the present invention may further include a shearing dispersion step, specifically, the shearing dispersion step is also performed after the above-mentioned sanding composition is discharged to obtain the whiteboard pen ink.

[0086] Those skilled in the art can understand that the composition is fed at one time or in batches, both of which belong to the scope of the present invention. When feeding at one time, for example, all the components of the composition are subjected to a sanding step, and the shear dispersion step is performed after discharge; when feeding in batches, for example, part of the solvent component and the matting agent of the composition are added during shear dispersion .

[0087] In a specific embodiment of the present invention, the preparation method is as follows:

[0088] Formula: 1-10% of pigment, 60-95% of lower fatty alcohol (including polyol), 2-10% of resin, 1-10% of auxiliary agent (including dispersant, plast...

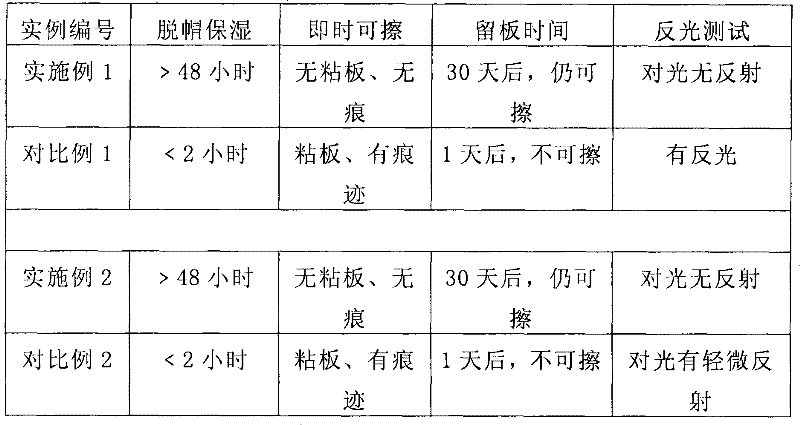

Embodiment 1

[0102] According to the formula, 10g of carbon black, 40g of ethanol, 18g of propylene glycol, 10g of resin polyvinyl butyral, 4g of dispersant CH-10S, 4g of plasticizer sebacate, 3g of humectant decaglyceryl laurate, peeling 5g of liquid paraffin, 4g of wetting agent W-9700, 18g of water and other materials were added, pre-mixed for 2 hours, and then subjected to ultra-fine sanding. Material; according to the requirements, use 30g of isopropanol and 66g of ethanol as a solvent, add 4g of matting agent to prepare, and obtain the finished whiteboard pen ink after shearing and dispersing for 1 hour.

Embodiment 2

[0104] According to the formula, 10g of pigment, 30g of ethanol, 10g of isopropanol, 10g of glycerol, 10g of resin carboxymethyl cellulose, 4g of dispersant CH-10S, 4g of plasticizer adipate, and humectant ten polyglycerol lauryl Add 3g of acid ester, 5g of stripping agent liquid paraffin, 4g of wetting agent HX-5810, and 10g of water, pre-mix for 1 hour, and then perform ultra-fine sanding. The temperature is controlled at 40-60°C, and the pressure is about 7 After 1 hour, the material is discharged; according to the requirements, use 95g of ethanol as a solvent and 5g of a matting agent to prepare, and after shearing and dispersing for 5 hours, the finished whiteboard pen ink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com