Inner diameter detection device of the fixed tapered hole in the center of textile spinning frame

A textile spinning frame and testing device technology, applied in mechanical measuring devices, measuring devices, using mechanical devices, etc., can solve the problems of wear, inability to detect or calibrate, and decrease in the accuracy of regular inspections, and achieve fast and accurate detection, reliable guarantee, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

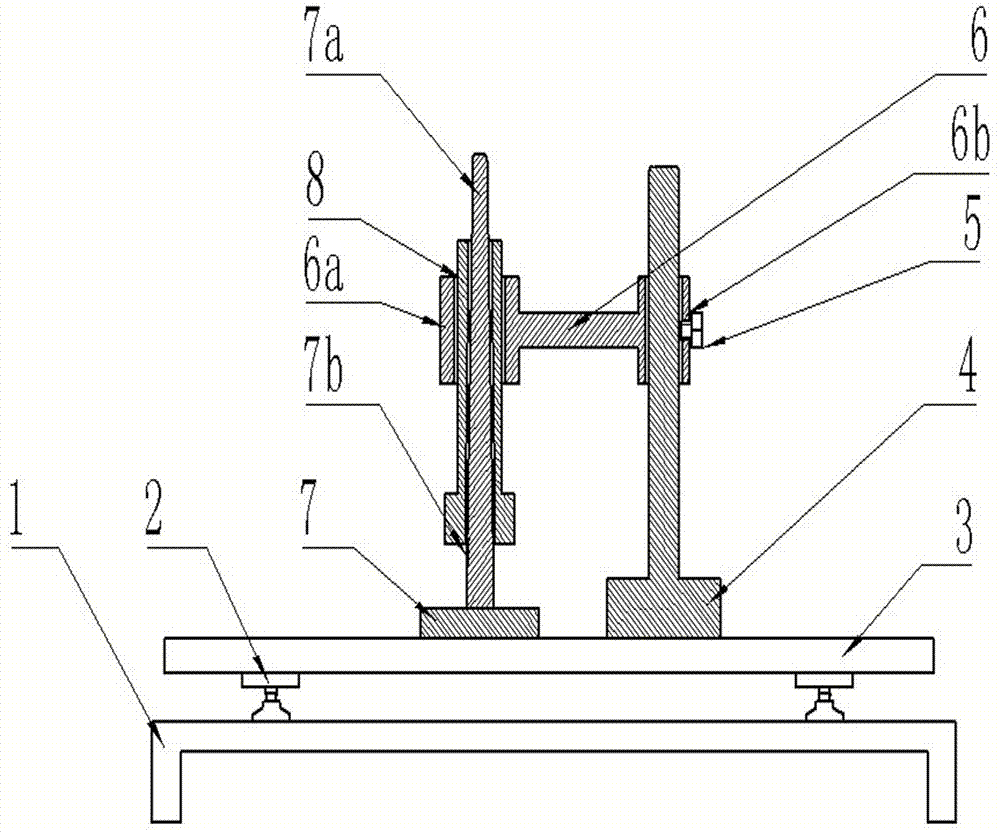

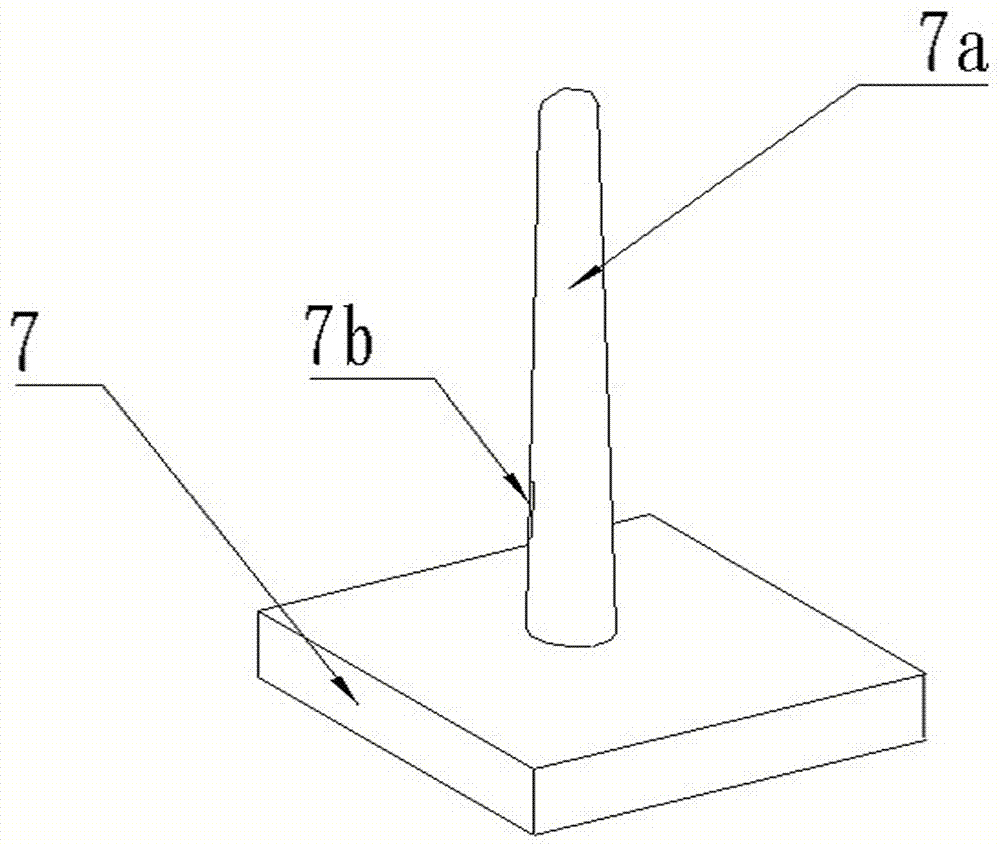

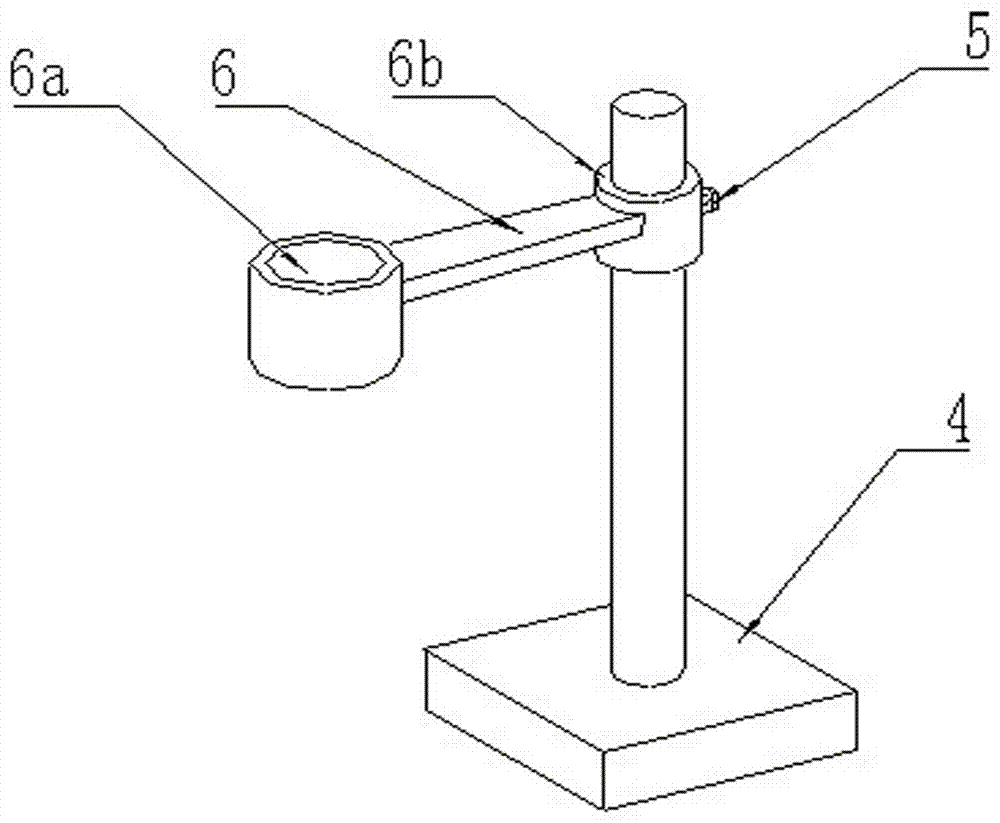

[0011] Such as figure 1 , figure 2 , image 3 As shown in the present invention, a device for detecting the inner diameter of a fixed cone hole in the center of a textile spinning frame comprises a base 1, an operating platform 3 is arranged on the base 1, and several leveling mechanisms 2 are arranged between the base 1 and the operating platform 3, The operating platform 3 is provided with a square base 7, the square base 7 is provided with a tapered rod 7a in the center, and a scale 7b is provided below the tapered rod 7a; one side of the square base 7 is provided with a "⊥" shaped Bracket 4, above the "⊥" shaped bracket 4 is movably connected with an "H" shaped connecting rod 6 through an adjusting bolt 5, and the "H" shaped connecting rod 6 is provided with a left positioning sleeve 6a and a right positioning sleeve 6b.

[0012] The tapered rod 7a and the "⊥"-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com