Light portal type engraving and milling machining center

A machining center, gantry-type technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize centralized processing of multiple processes, low engraving and milling efficiency, etc., to save costs, improve production efficiency, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further described:

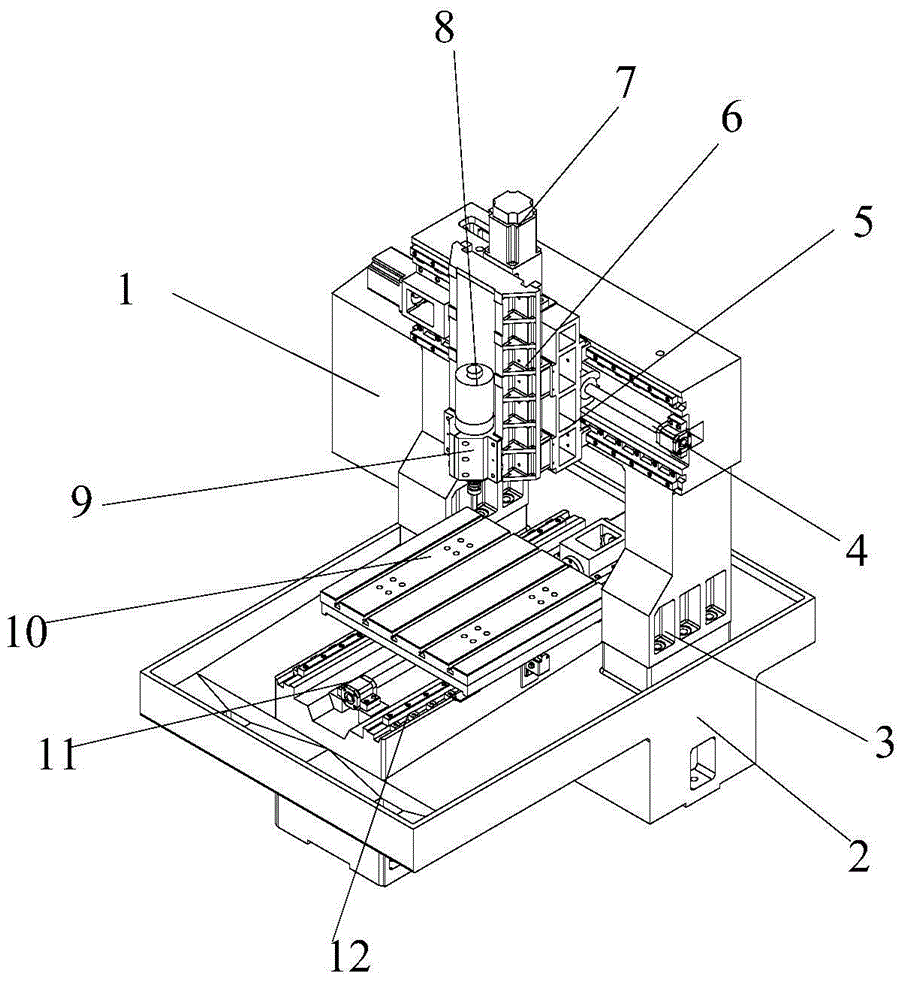

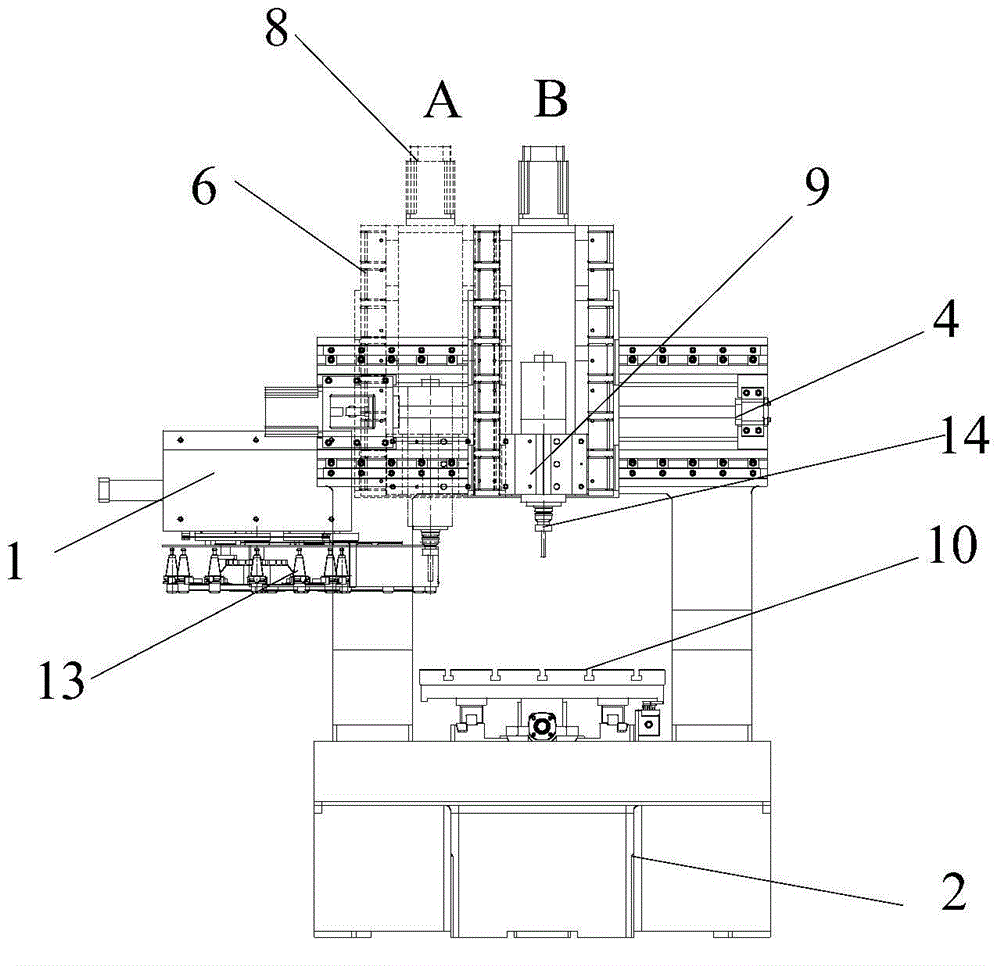

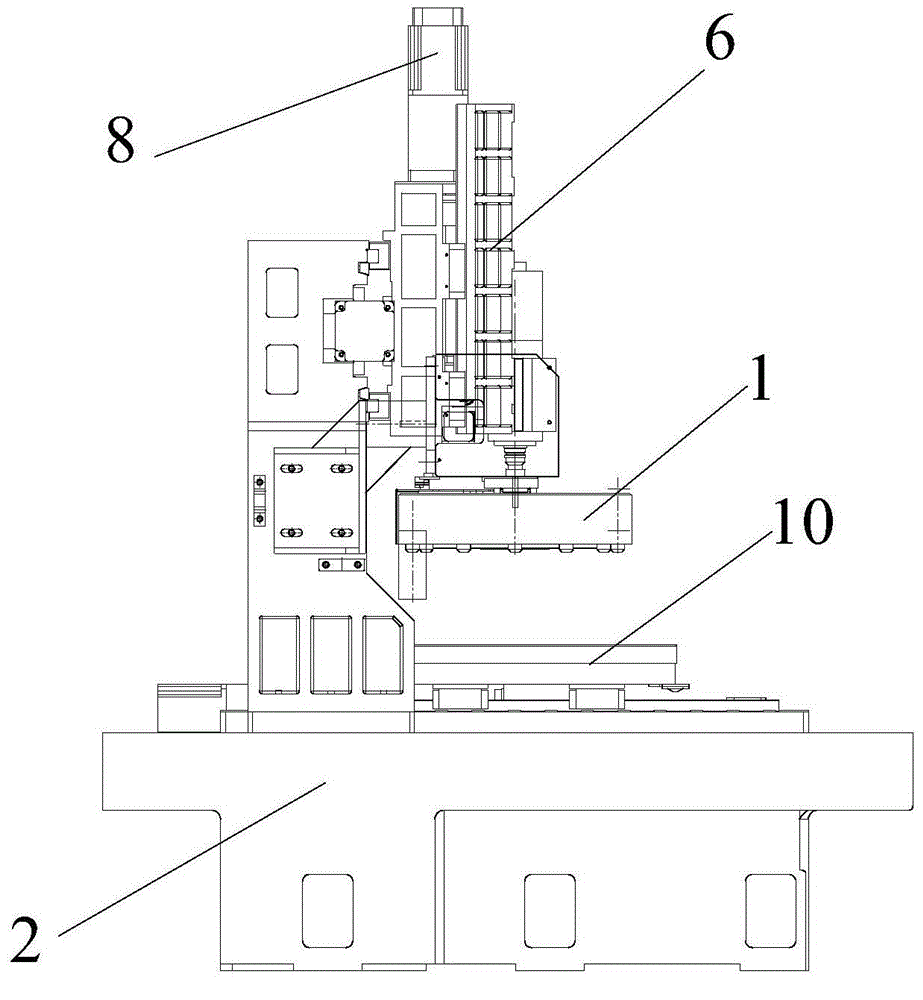

[0019] A light-duty gantry-type engraving and milling machining center, which is composed of a PC, a control system, and a machine tool body. The machine tool body includes a bed 2, a column 3, an X-axis screw rod 4, an X-axis carriage 5, a Z-axis slide plate 6, and a Z-axis Servo motor 7, workbench 10, Y-axis screw rod 11, tool magazine 1, tool changing device 13 and tool 14, the X-axis screw rod 4 is arranged on the column 3, and the X-axis carriage 5 can be slidably arranged on On the X-axis screw 4, the tool magazine 1 and the tool changing device 13 are arranged on one side of the bed 2, and the bed 2 is also provided with a line rail 12, and the workbench 10 passes through the Y-axis screw 11 It can be slidably arranged on the line rail 12, and the X-axis carriage 5 is provided with a Z-axis slide plate 6 and a Z-axis servo motor 7, and the Z-axis slide plate 6 is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap