Plate feeding machine

A technology of sheet metal and feeding machine, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of slow loading and low efficiency, and achieve the effect of high loading efficiency, stable performance, flexible and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

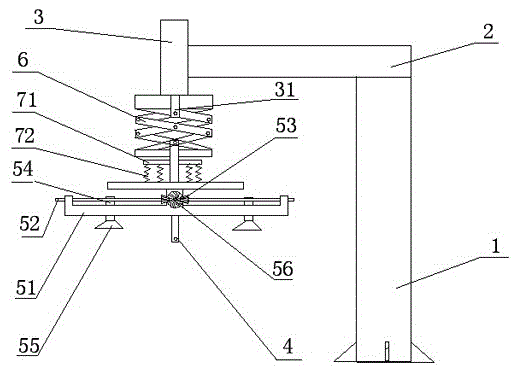

[0013] Such as figure 1 As shown, a plate loading machine includes a column 1, a cross arm 2, a vertical oil cylinder 3, a suction cup mechanism, a stroke mechanism, and a position sensor 4,

[0014] The top of the column 1 is connected to one end of the cross arm 2 through a rotating mechanism, the cross arm 2 rotates 360 degrees around the column, and the other end of the cross arm 2 is fixedly connected to the vertical cylinder 3,

[0015] The suction cup mechanism comprises a suction cup frame 51, a suction cup motor, and two ball screw screws 52. Two ball screw screws 52 are installed inside the suction cup frame, and an umbrella wheel 53 is installed at one end of the ball screw screw 52, and two umbrella wheels 53 are connected with the suction cup motor shaft. The umbrella wheel 56 of the motor cooperates, and the sucker 55 is installed on the bottom of the screw nut 54,

[0016] The stroke mechanism is a scissor-type lifting frame 6, the upper end is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com