AGV elastic support driving device with hub motor

A technology of in-wheel motor and drive device, which is applied to power devices, casters, wheels, etc., can solve the problems of automatic adaptation and adjustment of multi-stage reducers, oversize and shrinkage, etc., to improve accuracy and stability, reduce vibration, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

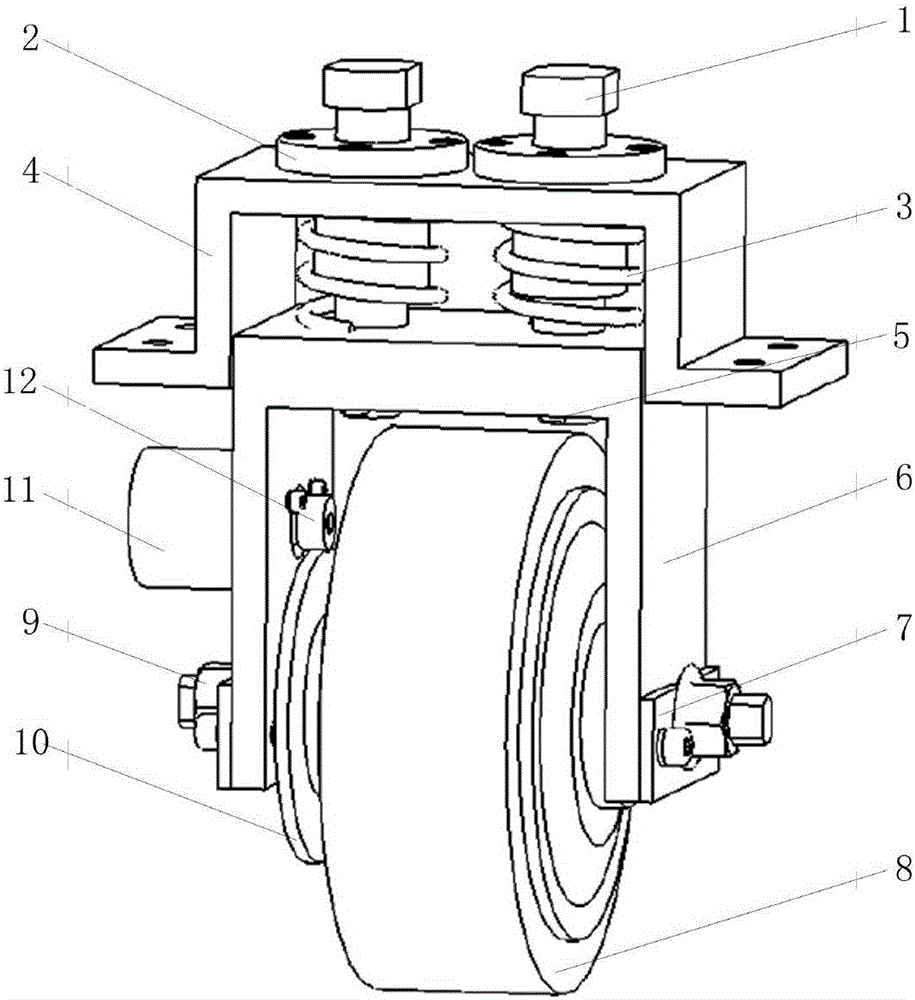

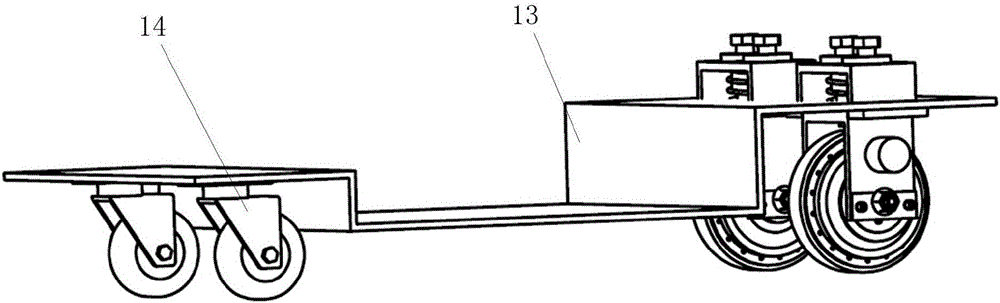

[0018] An AGV elastic support drive device using hub motors, such as figure 1 As shown, the linear sliding bearing 2 with flange is fixed on the supporting frame 4, the threaded end of the guide rod 1 passes through the linear sliding bearing 2 with flange, the cylindrical coil spring 3 is placed on the lower part of the guide rod 1, and the end of the lower part of the guide rod 1 Be threaded and be connected and fixed with the driving wheel bracket 6, the lower end of the guide rod 1 is drilled with a through hole and place the cotter pin 5, and the cotter pin 5 is close to the driving wheel bracket 6 to prevent the guide rod 1 from loosening during the movement of the car body. The two ends of the main shaft of the hub motor driving wheel 8 are set on the U-shaped groove of the driving wheel bracket 6, and the U-shaped groove of the anti-loosening piece 7 is sleeved on the overhanging part of the main shaft of the hub motor driving wheel 8 and fixed on the driving wheel brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com