Balance chain automatic tensioning guiding device for elevator balance chain vanning equipment

A guiding device and chain packing technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem of not meeting the requirements of high-quality balanced chain packing, manual auxiliary workload and high work intensity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

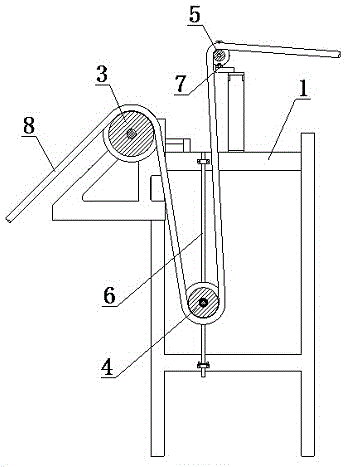

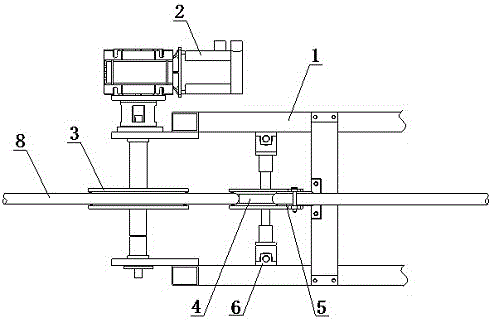

[0012] An automatic tensioning guide device for a balance chain used in elevator balance chain packing equipment, such as figure 1 , figure 2 As shown, it includes a frame 1, the frame 1 is provided with a traction wheel 3 driven by a servo motor 2, and a lifting tension pulley 4 and a guide pulley 5, and the two ends of the axle of the lifting tension pulley 4 are slidably Assembled on a pair of self-driving guide rails 6, the self-driving guide rails 6 are vertically installed on the frame 1. The lifting tensioning wheel 4 can self-adaptively slide up and down on the self-driving guide rail 6 under the action of the self-driving guide rail 6, thereby realizing the automatic tensioning effect on the balance chain 8.

[0013] Near the upper and lower ends of the self-driving guide rail 6, a proximity switch for the lifting tension wheel 4 is provided to avoid the failure of the subsequent packing process of the packing equipment due to poor feeding of the packing equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com