Support structure for chimney internal steel cylinders

A supporting structure and steel inner cylinder technology, which is applied in the support field of supporting structures and steel inner cylinders of suspended chimneys, can solve the problems of safety of the supporting structure, reduce the engineering amount, hidden dangers, etc., achieve reasonable force, reduce the engineering amount, The effect of small moment arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

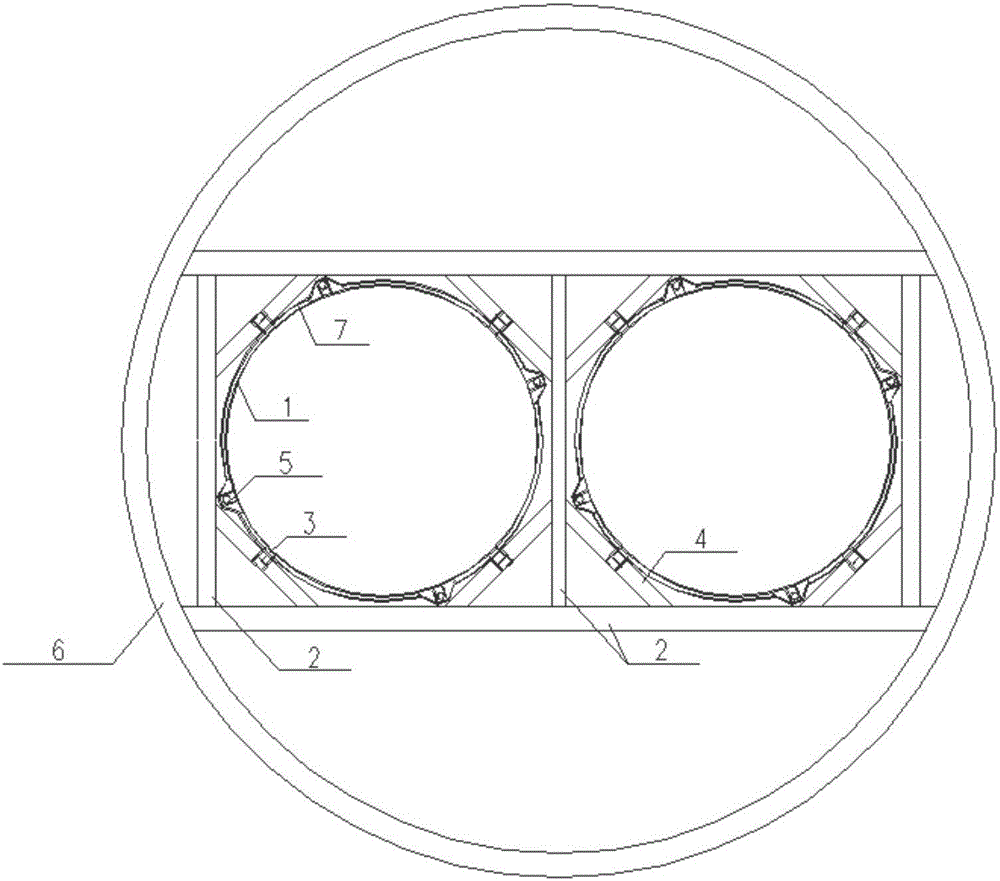

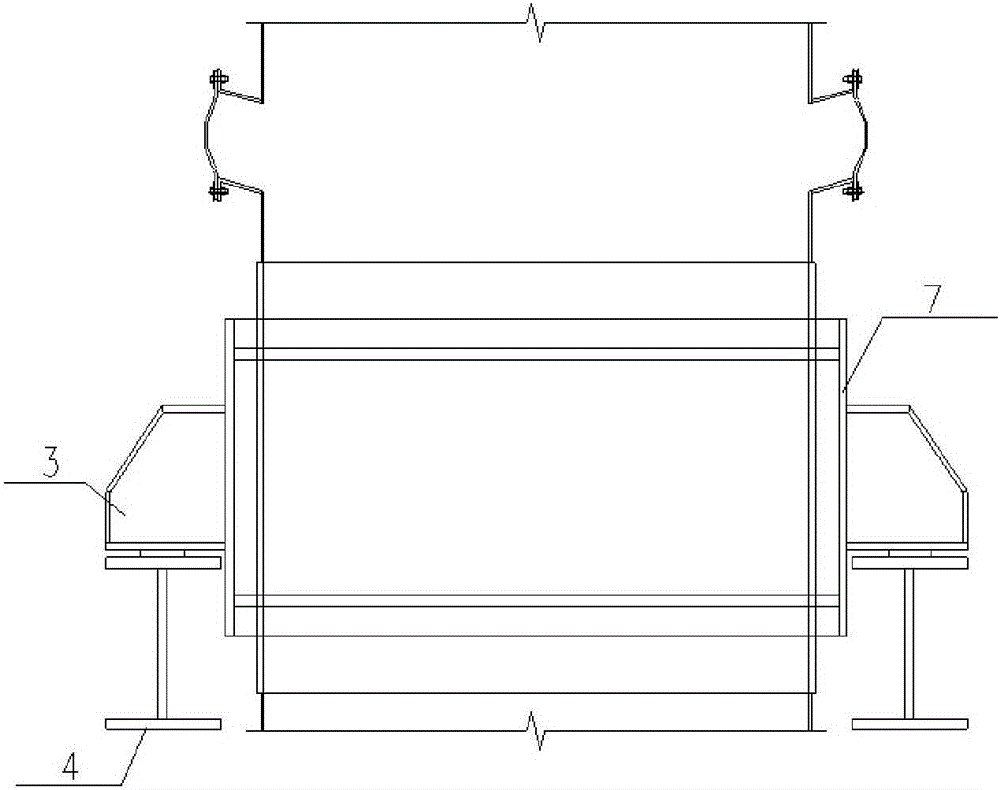

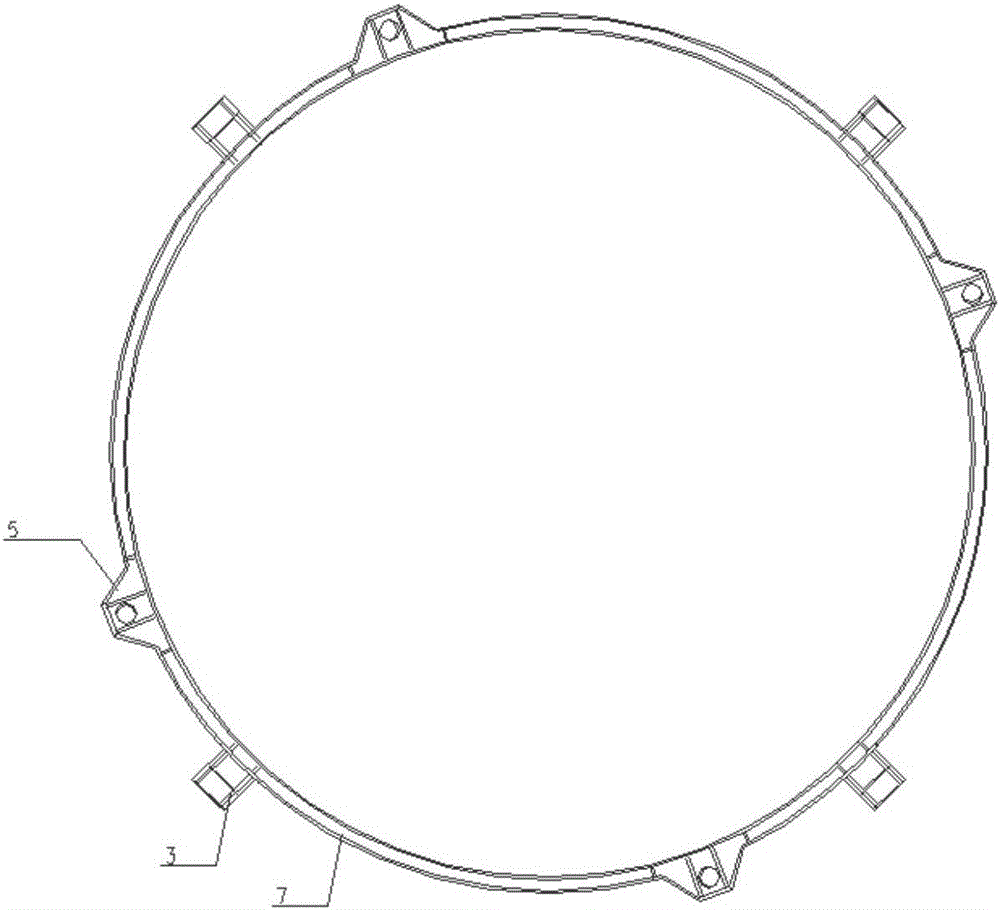

[0031] refer to Figure 1-Figure 6 , the present embodiment includes a chimney concrete outer cylinder 6 and a steel inner cylinder 1, the steel inner cylinder 1 is located in the inner cavity of the chimney concrete outer cylinder 6; a reinforcing ring 7 is sleeved on the outer surface of the steel inner cylinder 1 and several steel corbels are set 3 and several hoisting lugs 5, the inner cavity of the chimney concrete outer cylinder 6 is provided with a square frame body 2 surrounded by several steel beams, the steel inner cylinder 1 is located in the square frame body 2, and the steel inner cylinder 1 Hanging on the square frame body 2 to form a hanging hoisting structure; the steel corbel 3 is located at the top corner of the square frame body 2, and the bottom of the steel corbel 3 is connected with a corbel steel beam 4, and the corbel steel beam 4 The two ends of each are fixedly connected with the adjacent steel beams of the square frame body 2 to form the longitudinal...

specific Embodiment 2

[0044] refer to Figure 5 and Figure 6, The characteristics of this embodiment 2 are: in addition to the structure of the specific embodiment 1, a steel beam stiffener 9 parallel to the longitudinal axis of the steel inner cylinder 1 is provided inside the corbel steel beam 4 . A backing plate 12 is provided at the junction of the steel corbel 3 and the corbel steel beam 4 . Two angle steels 8 are arranged on the longitudinal axis of the corbel steel beam 4 . The overall structure of the angle steels 8 is in the shape of a right angle. A right-angled triangle 11 is arranged on the corbel steel beam 4 , and the right-angled end of the right-angled triangle stiffening plate 11 is arranged correspondingly to the right-angled mouth of the angle steel 8 .

[0045] Principle of this embodiment:

[0046] The limit device is arranged on the corbel steel beam 4, that is, the angle steel 8 is welded on both sides of the steel corbel 3 to limit the lateral displacement of the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com