Parallel disk material properties experiment device

A technology of material properties and experimental devices, applied in the direction of measuring devices, analyzing materials, strength characteristics, etc., can solve the problems of small range of materials and the initial stage of smart materials, and achieve the effects of large range of changes, accurate changes, and diverse functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

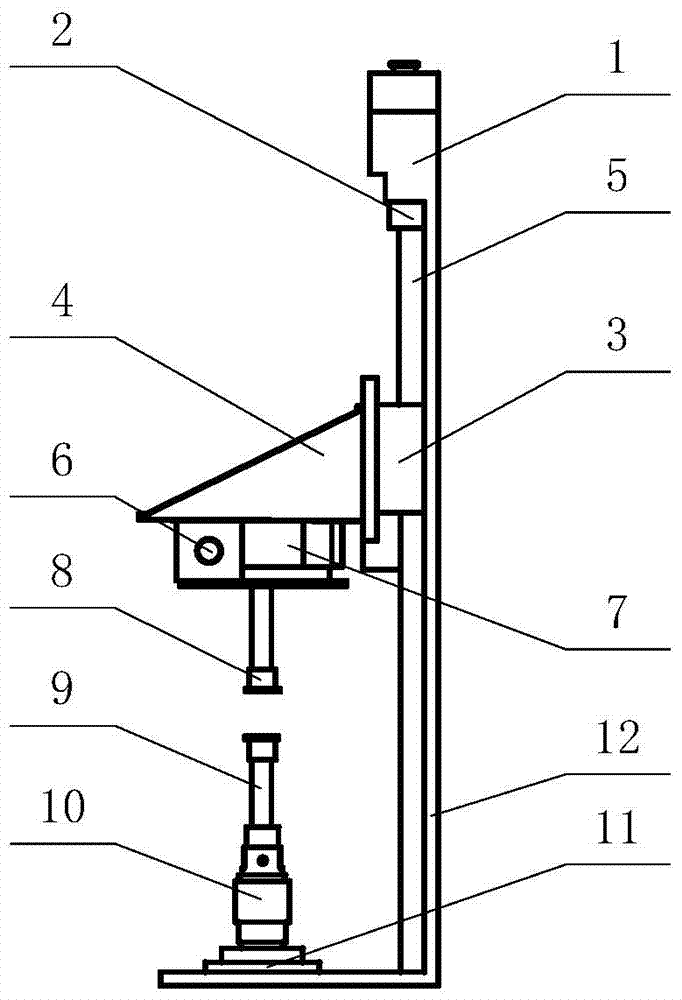

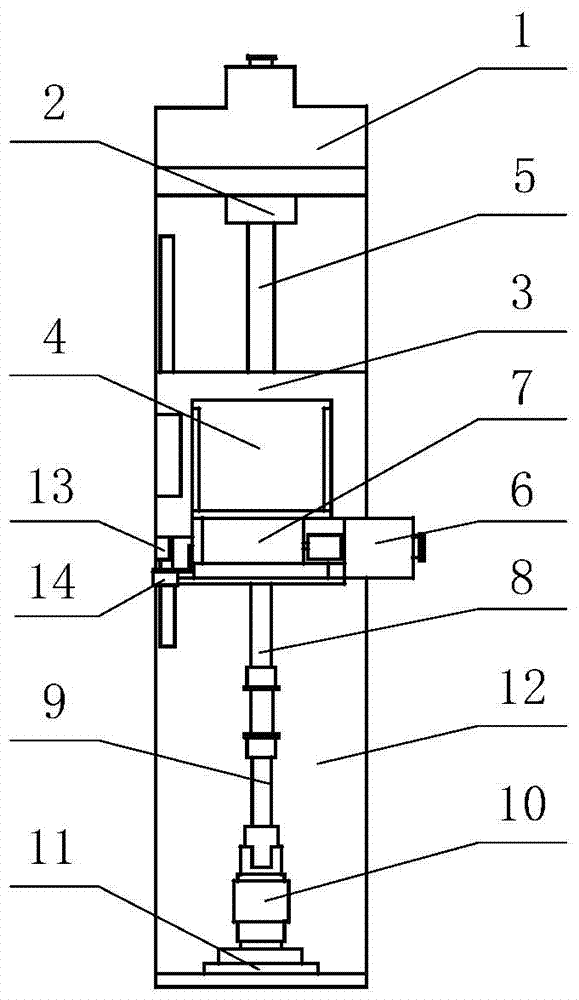

[0027] refer to figure 1 and 2 , a kind of parallel disc type material property experiment device, comprises a group of corresponding upper parallel disc 8, lower parallel disc 9 and pc machine; An extrusion loading motor 1 is fixedly installed on the upper end of an L-shaped frame 12, and is fixedly located on The vertical guide rail 5 of frame 12 is provided with the slide block 4 that can move along this guide rail, and the output shaft of extrusion loading motor 1 is connected with slide block 4 by coupling 2 and lead screw nut pair 3; The lower end of the lower end is fixed with a speed reducer 7 driven and connected by the shear loading motor 6, the output shaft of the speed reducer 7 is fixedly connected with the upper parallel disk 8, and the lower end of the lower parallel disk 9 passes through the torque sensor 10 in turn. and the pressure sensor 11 are fixed on the base of the L-shaped frame 12;

[0028] A linear displacement sensor 13 is provided on the slider 4,...

Embodiment 2

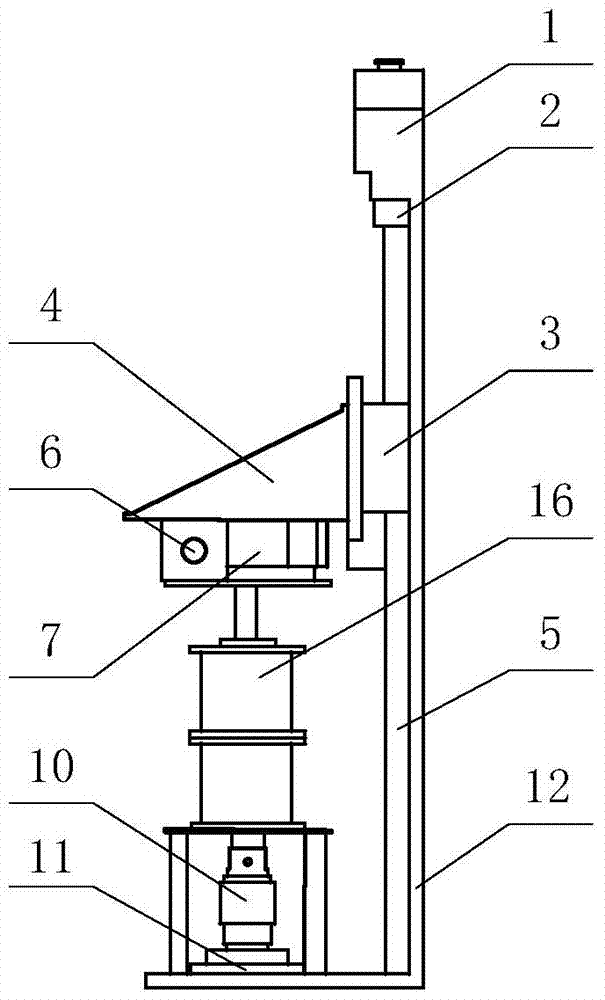

[0048] refer to image 3 , 4, adding the following settings to the structure of Example 1, material property experiments of smart materials such as magnetorheological fluids and magnetorheological elastomers can be realized. That is, it includes a linear Hall sensor 15 embedded on the surface of the lower parallel disk 9 and two excitation coils 16 that are respectively sleeved on the outer circumference of the upper parallel disk 8 and the lower parallel disk 9 and are respectively electrically connected to a DC power supply. The linear Hall sensor 15 communicate with the PC through the data acquisition card. The upper and lower parallel disks are made of magnetically permeable material.

[0049] Under this structural device, through the driving of the extrusion loading motor 1, the upper parallel disk 8 moves up and down to realize the extrusion of the measured material sample placed between the upper and lower parallel disks; through the shear loading motor 6 Driven to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com