White board calibration target of material separation equipment

A sorting and equipment technology, which is applied in the field of whiteboard calibration targets, can solve the problems of time-consuming and complicated operation, and achieve the effect of short time-consuming and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

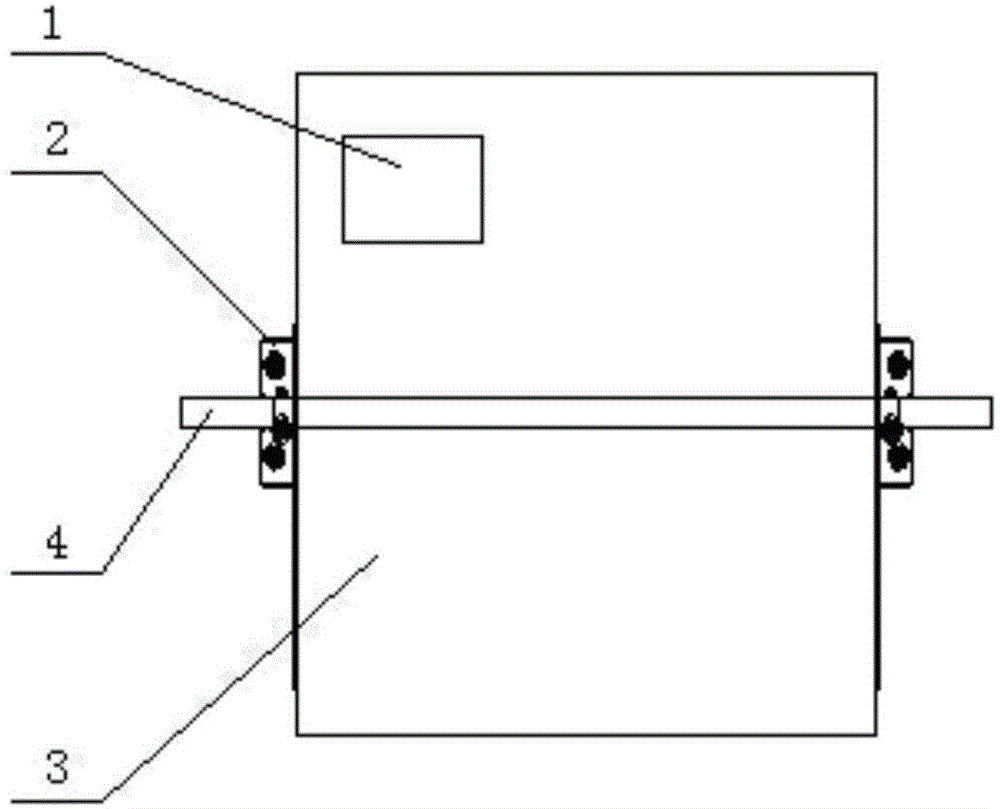

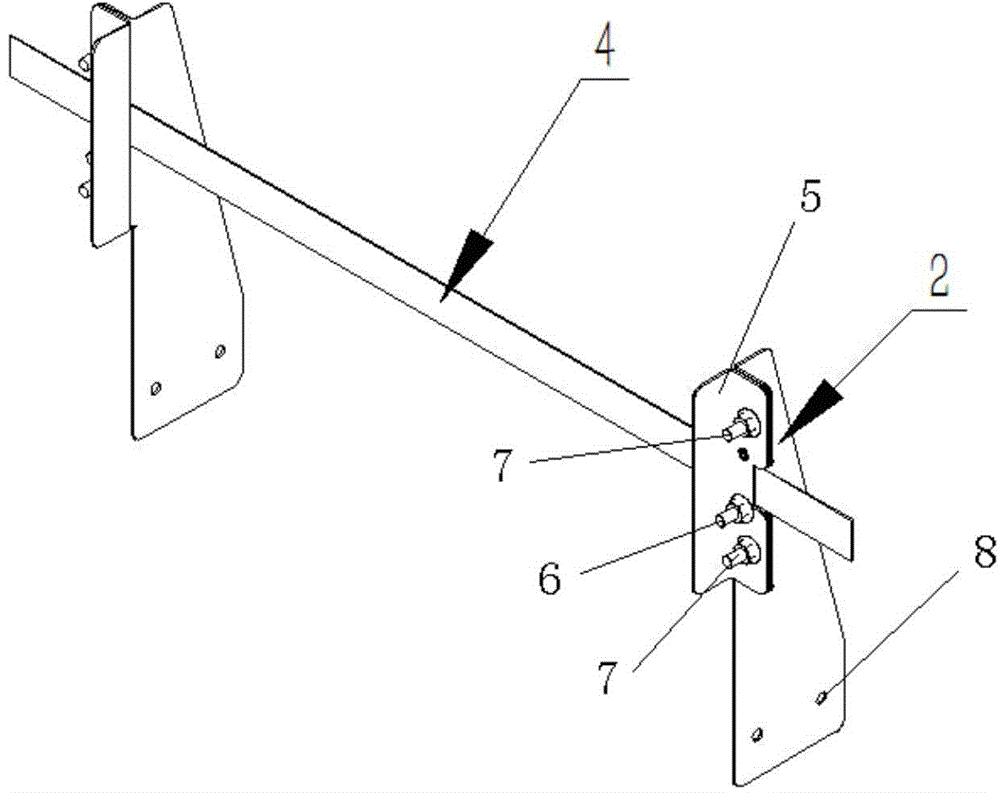

[0016] Such as figure 1 , 2 Shown: a whiteboard calibration target for material sorting equipment, including a positioning module 2, a calibration white bar 4, and a buckle 5, and the two ends of the calibration white bar 4 are installed on the positioning module 2 through the buckle 5 when in use, The positioning module 2 is installed on the material sorting equipment 3, and the positioning module 2 is used to adjust the precise position of the calibration white bar 4, so that the centerline position of the calibration white bar 4 is consistent with the point of view of the material sorting equipment 3. Consistent; the material sorting device 3 is also provided with a storage box 1, and the storage box 1 is used to store the calibration white strip 4 when not in use, so as to ensure that the surface of the calibration white strip 4 is clean. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap