Prefabricated cabin temperature control method, prefabricated cabin temperature control system and prefabricated cabin

A temperature control method and temperature control system technology, applied in the direction of temperature control using electric methods, can solve the problems of high failure rate and high maintenance frequency of the temperature control system, achieve the effect of reducing failure rate and maintenance frequency, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

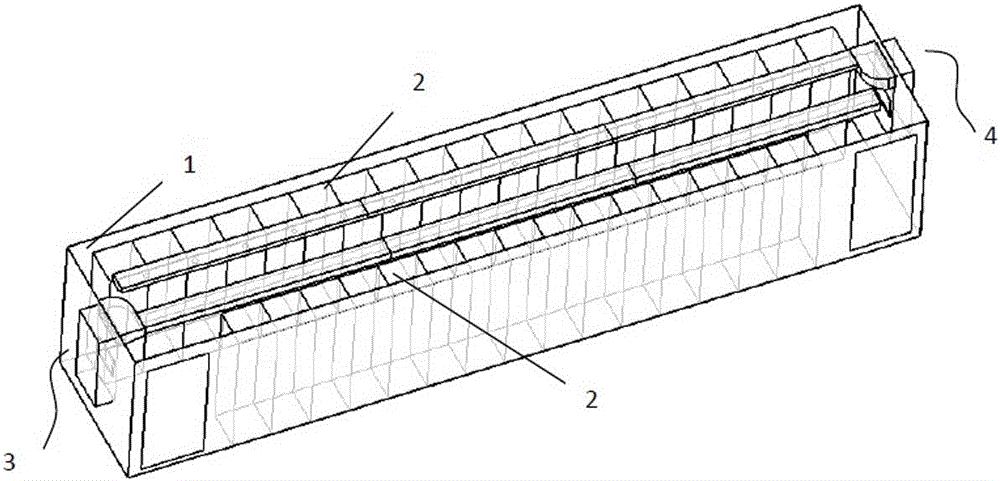

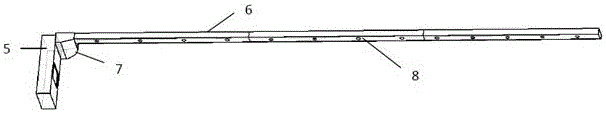

[0021] An example of the prefabricated cabin in the present invention is Figure 1~Figure 2 As shown, it includes a cabin body 1 , two rows of cabinets 2 arranged on both sides of the cabin body 1 in the width direction, and a temperature control system for adjusting the temperature of the air in the cabin body 1 . The temperature control system includes a first air conditioner 3 and a second air conditioner 4 respectively arranged on the bulkheads at both ends of the cabin body 1 in the longitudinal direction. The first air conditioner 3 and the second air conditioner 4 have the same structure and performance , that is, the cooling capacity and heating capacity of the two air conditioners are the same. Each air conditioner all comprises air conditioner 5, main air channel 6 and the connecting air channel 7 that is connected at the air outlet of main air channel 6 and air conditioner 5, and connecting air channel 7 forms closing structure, can improve main air channel 6 entran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com