Water-jet textile motor

A textile machine and motor body technology, applied in the field of water-jet textile motors, can solve the problems of loose equipment parts, reduced equipment life, no waterproof effect of the motor, etc., to achieve good stability, reduce motor life, and solve the problem of unreliable motor bases. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

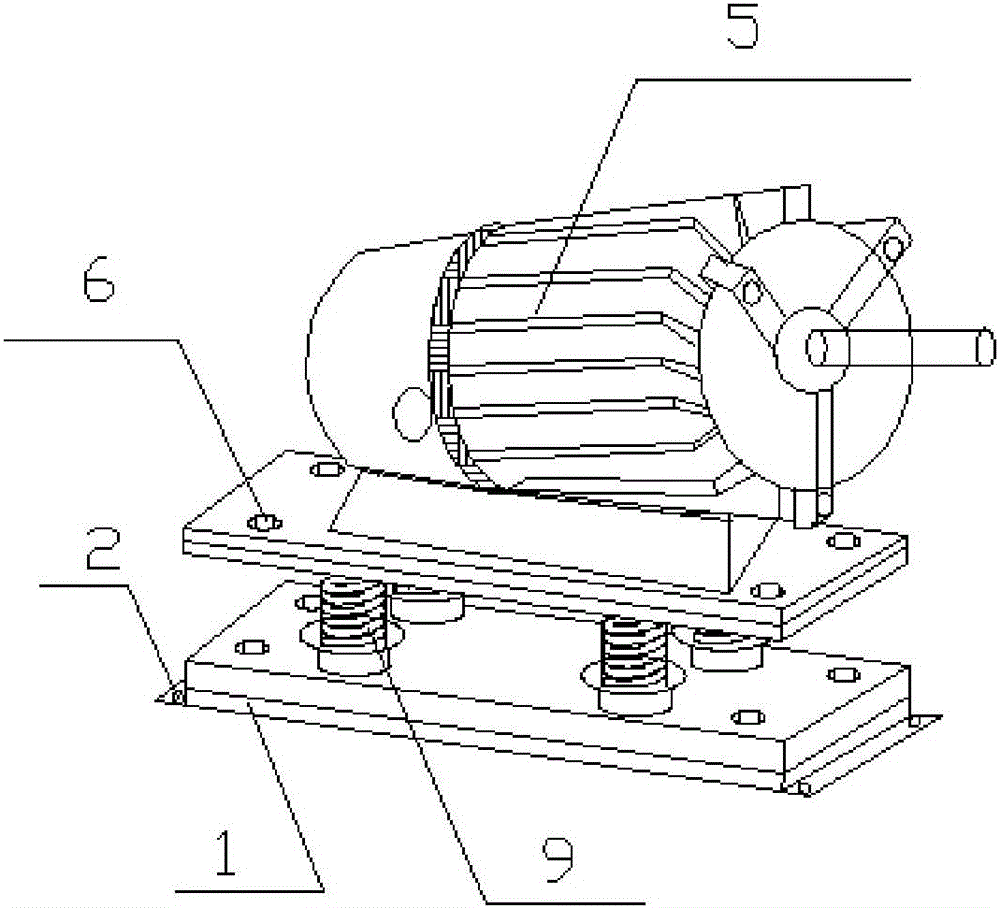

[0011] refer to figure 1 and figure 2 A water jet textile motor shown includes a fixed base and a motor body, the fixed base includes a fixed base 1, a bolt hole 2 and a buffer component 4, and the motor body includes a motor 5 and a waterproof cover (not shown), The buffer component 4 is arranged between the fixed base 2 and the motor 5, the fixed base 1 is fixedly arranged on the water jet textile machine or other table tops through the bolt holes 2, and the waterproof cover is arranged on each side seam of the motor 5 and connected place.

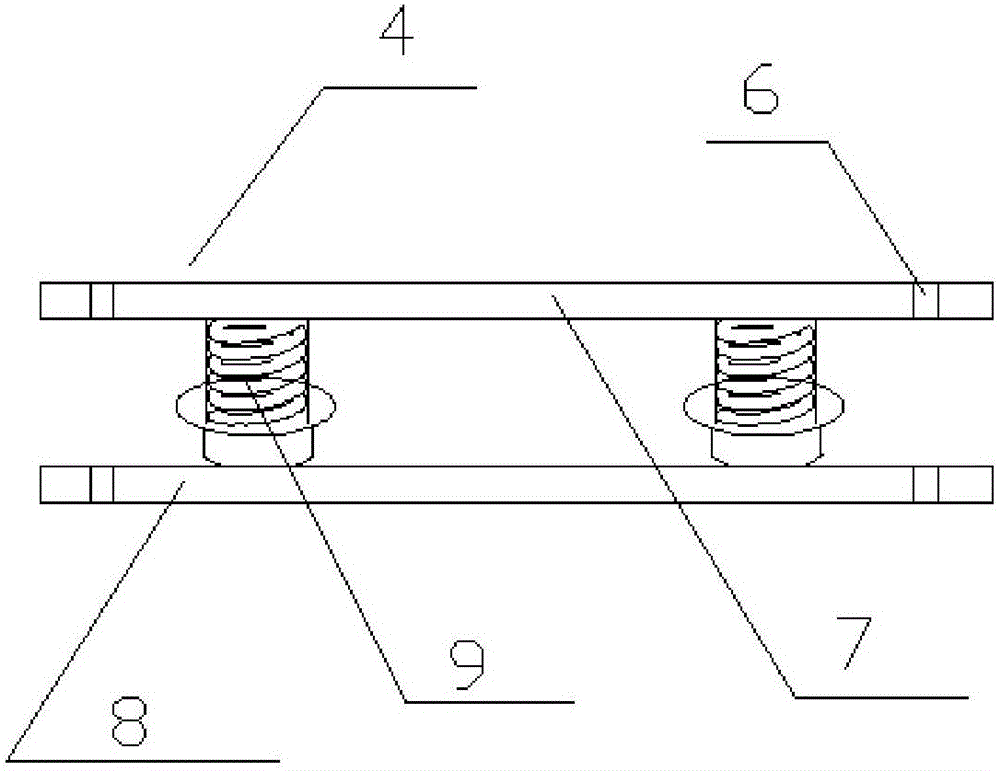

[0012] Described buffer member 4 comprises eight fixing holes 6, four springs 9, an upper support 7 and a lower support 8, and four of the eight fixing holes 6 are arranged on the four corners of the upper support 7, in addition Four are arranged on the four corners of the lower support 8, and corresponding steel-plastic combination sleeves (not shown) are arranged in each of the fixing holes 6 .

[0013] The waterproof cover is a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com