Fastening device for fastening a measuring pressure sensor, in particular tyre pressure sensor

A technology for measuring sensors and fastening devices, applied in fixing devices, detachable fasteners for friction clamping, tire measurement, etc., can solve problems such as damage to tire pressure sensors, and achieve the effect of reducing imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

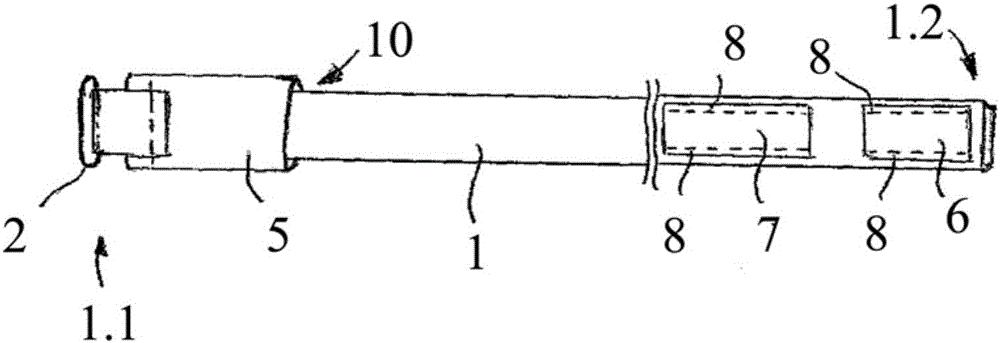

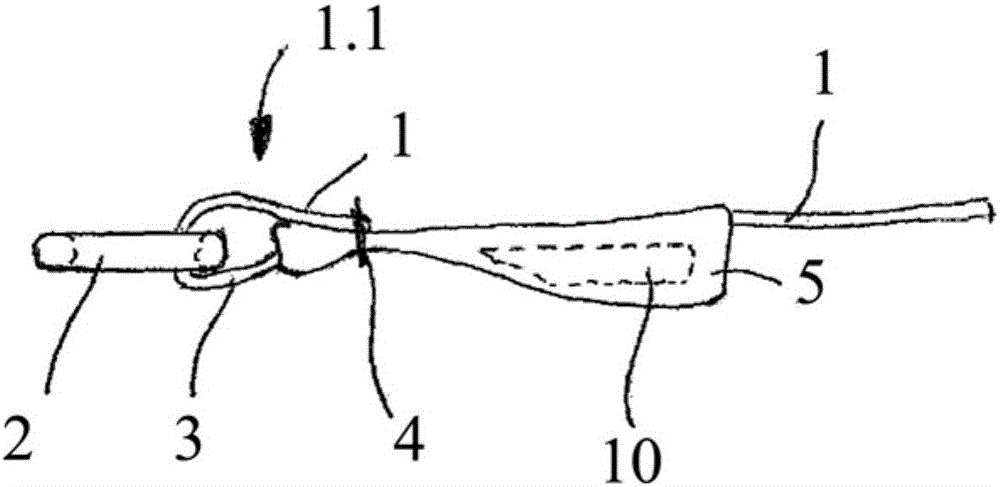

[0029] exist figure 1 shows a top view of a fastening device according to the invention with a band-shaped clamping band 1 which at a first end 1.1 carries an eye 2 through which a second end 1.2 can pass. eyelet 2 as in figure 2 At the first end of the clamping strap 1 shown in is accommodated in the loop 3, wherein the loop 3 is folded by the clamping strap 1 at its first end 1.1 and sewn in the region of the first end 1.1 Formed by folded sections on adjacent sections in , see seam 4. This seam 4 secures the receiving means 5 in the form of a tubular bag, preventing the bag from sliding in the longitudinal direction of the clamping band 1 . At the same time, the first end of the receptacle 5 is closed by the seam 4 , whereas the second end is designed as an open end through which the measuring sensor 10 , in particular a tire pressure sensor, is inserted into the receptacle. 5 and can be removed from it.

[0030] exist figure 1 , the measuring sensor is positioned in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com