A compression spring automatic separation device

A technology of automatic separation and compression of springs, applied in centrifuges and other directions, can solve the problem that springs cannot be separated and discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

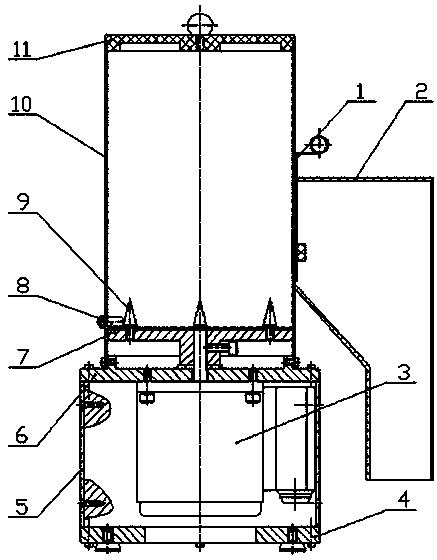

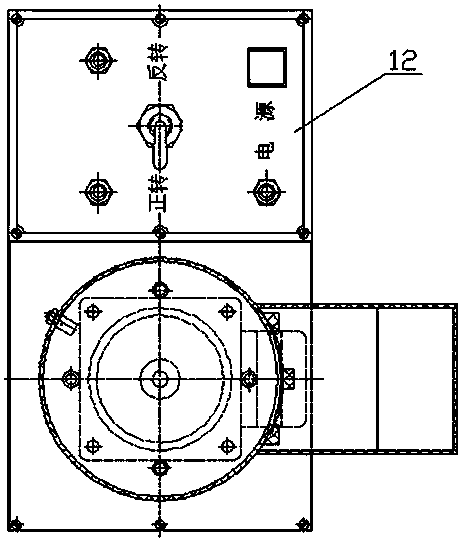

[0013] As shown in the figure, the mounting base 6, the side plate 5, and the bottom plate 4 form the installation space of the motor 3. The material cylinder 10 is installed on the mounting base 6, and the bottom of the material cylinder 10 is provided with a turntable 7. The turntable 7 is connected to the motor, and four agitators are installed on the upper surface. Cone 9. A stop pin 8 is also installed on the side wall of the barrel 10, and the stop pin 8 is slightly higher than the upper surface of the turntable 7, and the distance between the two is no more than 0.5 mm. There is a cylinder cover 11 on the top of the barrel 10, and a discharge hole is set on the side wall. A discharge adjustment door 1 and a discharge port 2 are installed outside the discharge hole. The discharge adjustment door 1 can move up and down to adjust the size of the discharge hole. It is suitable for Springs of different sizes.

[0014] Mounting seat 6 side is provided with electrical control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com